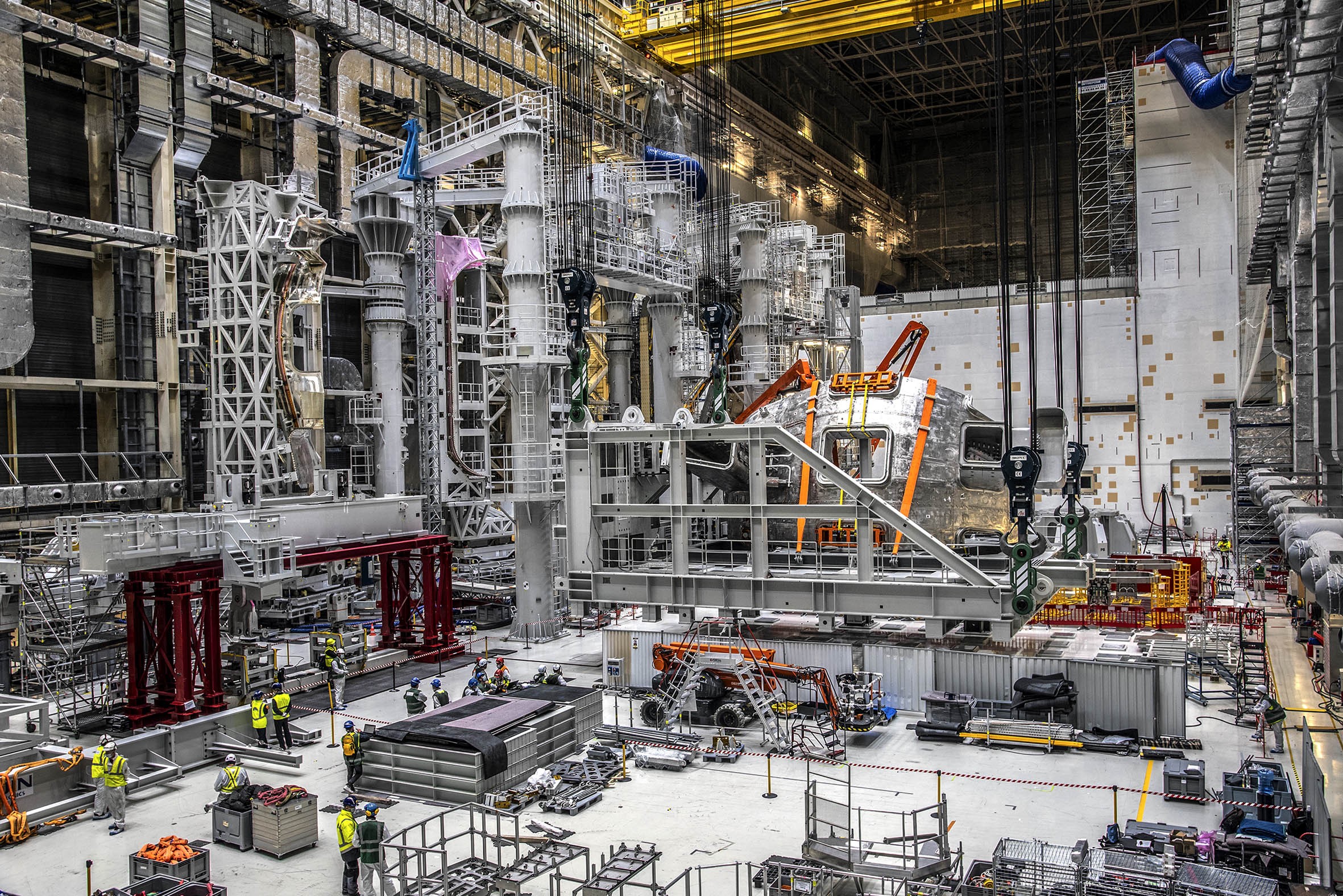

650 tonnes upended in mid-air

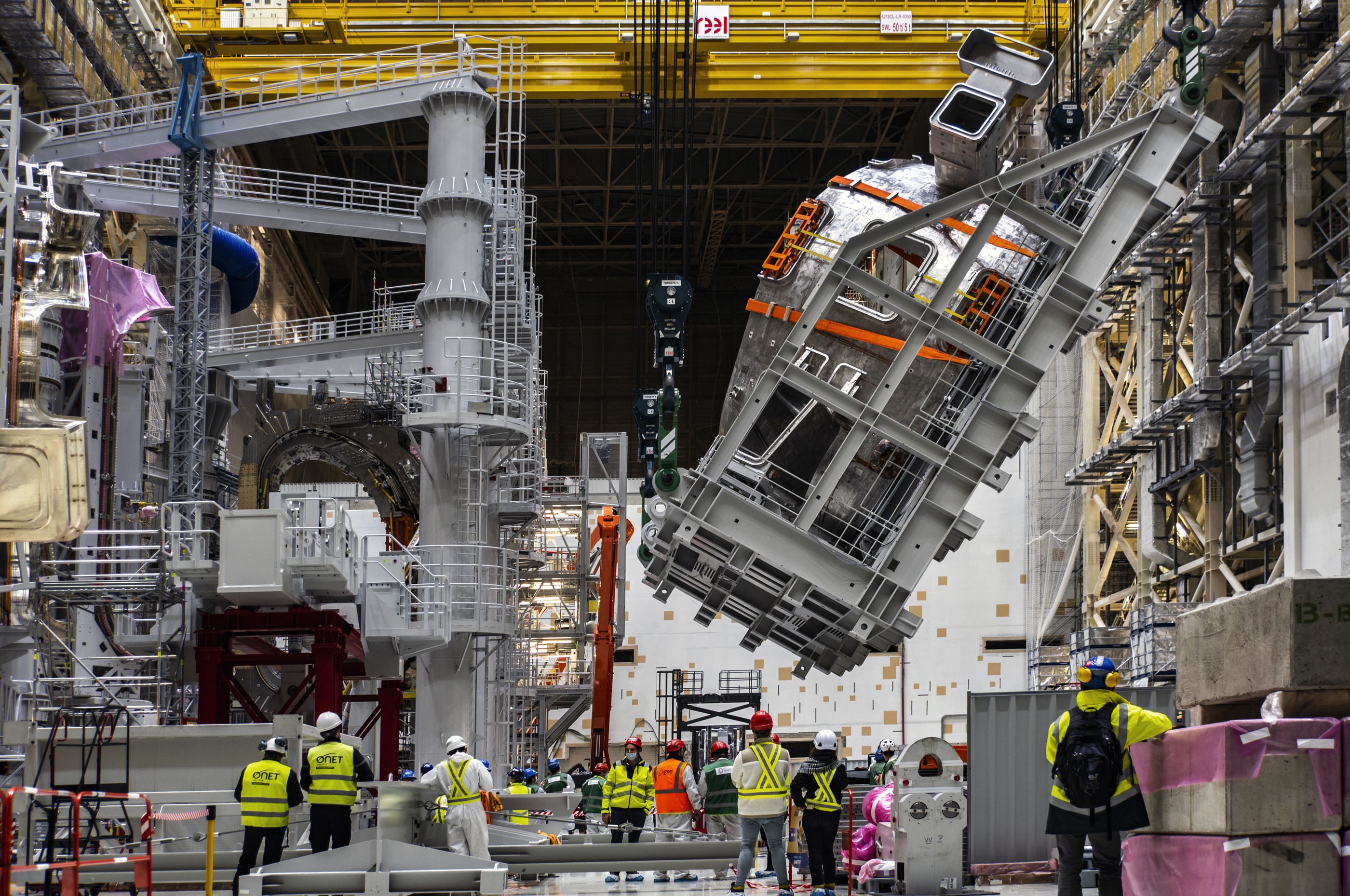

The upending of a vacuum vessel sector is one of the most spectacular of all pre-assembly operations. Not only is it a challenge to lift an extremely heavy and delicate load, but it also requires utmost precision to balance and tilt the load in mid-air.

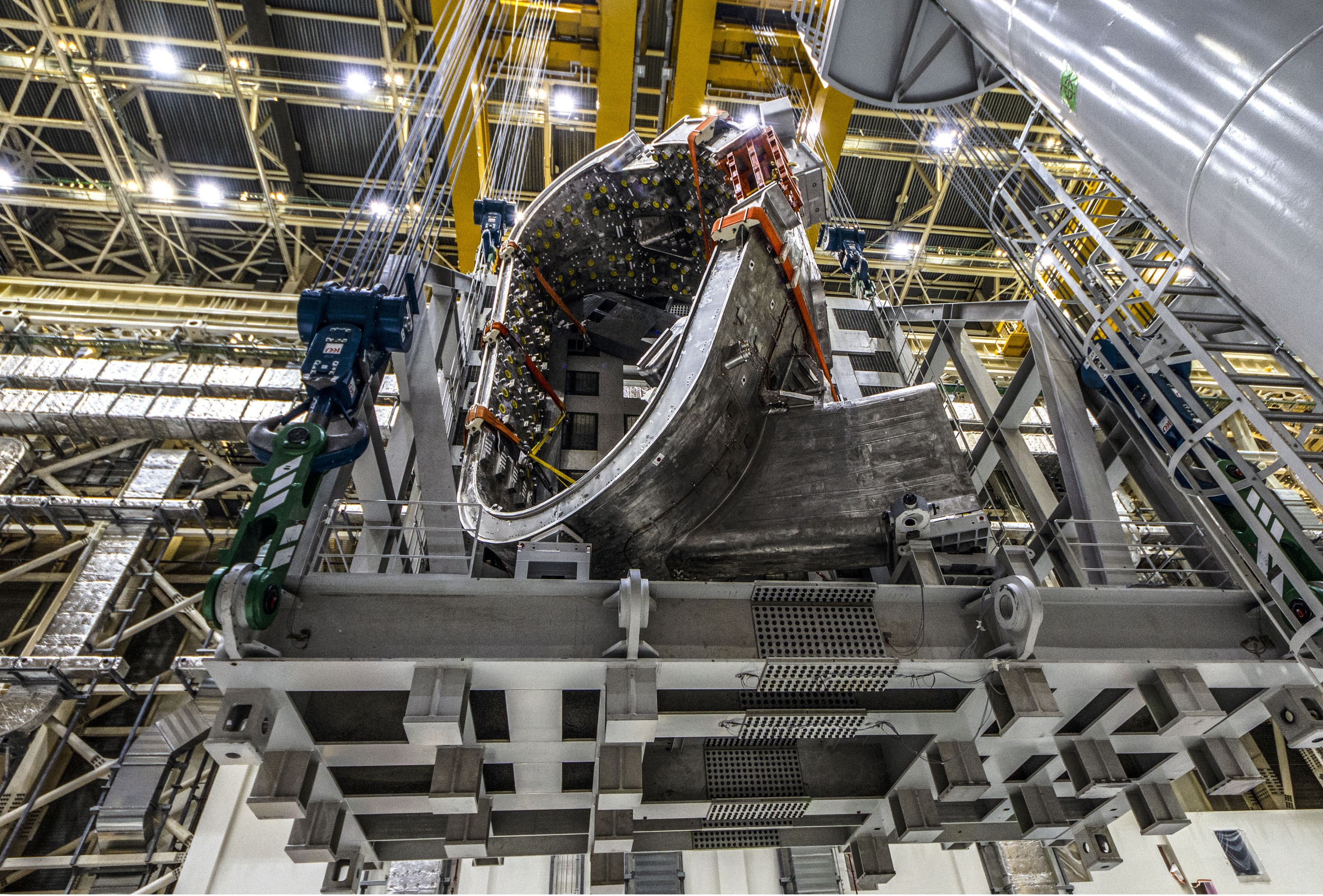

During the upending operation, the 40-degree section of the vacuum vessel—safely lashed to a bespoke frame called the upending tool—is slowly lifted from the horizontal to the vertical position. The move is required in order to align the component's lifting hooks to the complex crane rigging that will carry it across to the giant tool where the sector will be pre-assembled with other major components such as its thermal shield and associated vertical magnets, as well as many smaller items like linking structures and clamps.

In March 2021, the first vacuum vessel sector (#6) was successfully upended and positioned in the sub-assembly tool closest to the Tokamak Building. Since then, work has been underway to achieve the 27 "steps" required before the new sub-assembly can be transferred into the Tokamak pit. (The sub-assembly, or "module," forms the basic building block of the vacuum vessel's torus shape. Nine 40-degree modules are required to achieve the closure of the torus.)

On Thursday 9 December, as the first module was reaching the last stages of completion, a second vacuum vessel sector, #1(7), was upended and positioned facing the second standing tool, where it will transferred to follow the same sub-assembly steps as the first.

As the 650-tonne* load was slowly lifted and tilted, the atmosphere in the Assembly Hall was one of business as usual. Although an operation of this scope and complexity is never routine, the teams have now accumulated enough experience to feel perfectly confident in the face of the challenge.

* 440 tonnes for the component, and approximately 200 tonnes for the upending tool.