Science to resume at Wendelstein 7-X

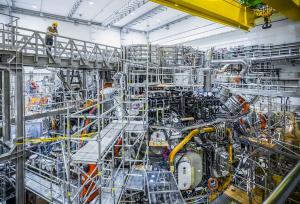

Improved equipment on Wendelstein 7-X will permit the stellarator device to achieve new scientific heights in a campaign planned to begin this autumn.

Science at the Wendelstein 7-X stellarator at the Max Planck Institute for Plasma Physics (IPP) in Greifswald, Germany, is progressing step by step in its quest to prove that the quality of the plasma confinement in a stellarator can reach the level of competing tokamak-type systems.

In the first two operational campaigns (2015/2016 and 2017/2018), scientists achieved significant milestones on the machine, obtaining a first plasma in helium in December 2015, a first plasma in hydrogen a few months later, and a record "triple product" value for stellarators in 2018. In the multiyear shutdown phase that followed, the goal was to transition to actively water-cooled components in the vacuum vessel to allow for a doubling of input heating and, in turn, improved performance.

Now, with 6.8 kilometres of cooling pipes (feeding 657 independent cooling circuits to in-vessel components), upgraded or new heating systems, and 40 new diagnostics, the fusion facility is ready, within a few years, to attempt plasma operations lasting for up to 30 minutes. The first experimental period of the new campaign is expected to last until March 2023

"With the improved equipment, we want to be able to keep high-performance plasmas with up to 18 gigajoules of energy turnover stable for half an hour in a few years," explains Professor Dr. Thomas Klinger, Head of Stellarator Transport and Stability Division, IPP, Greifswald. "Now it will be a matter of approaching this goal step-by-step and learning more about plasma operation at higher energies without putting too much stress on the machine too quickly."

See the original press release on the IPP website.