Removing, displacing and disassembling

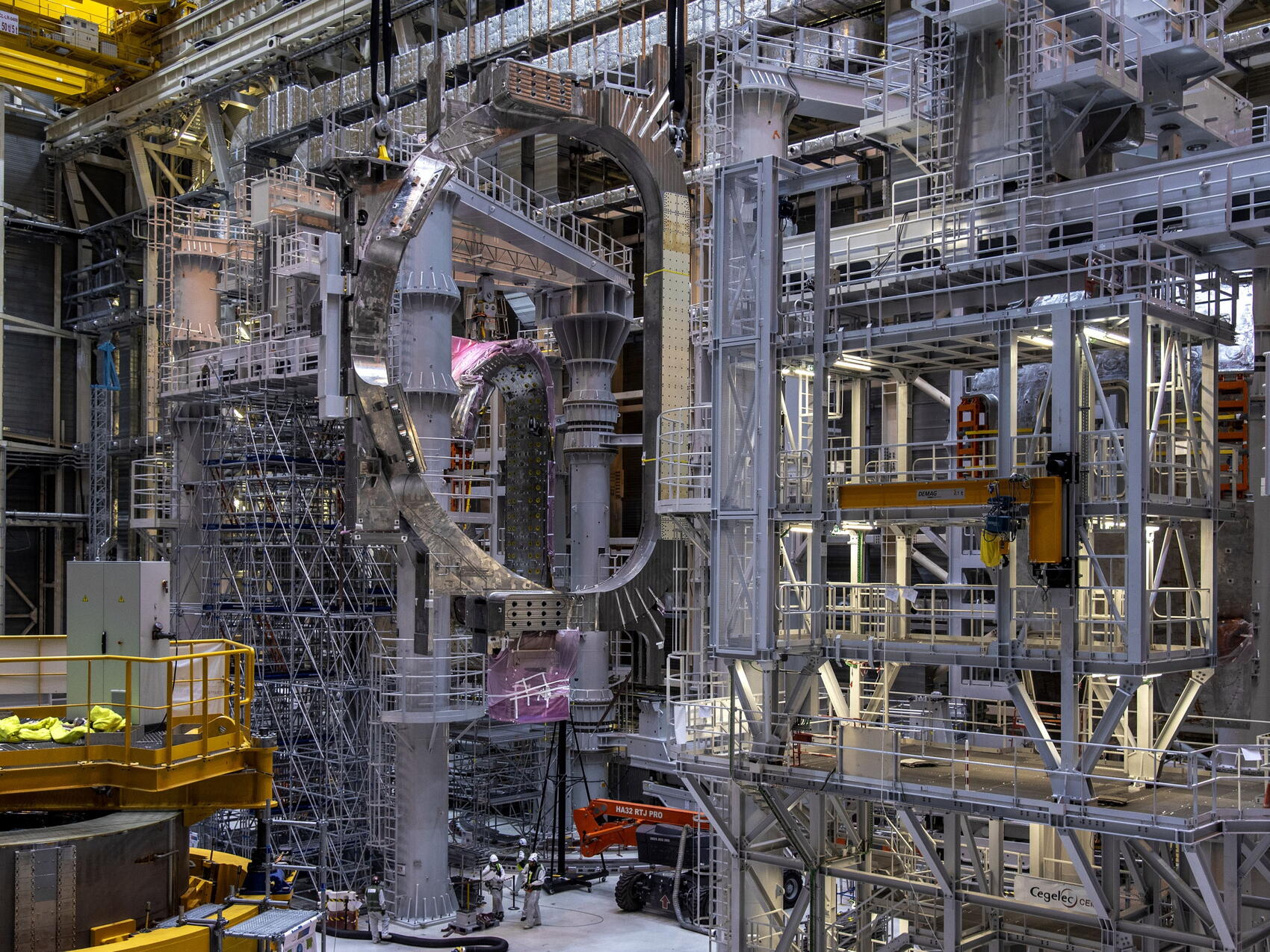

A good repair job starts with a cleared workbench, the right tools on hand and a strong vise. This axiom, true for odd jobs in a home workshop, is also true for the component repairs that ITER is preparing for. In this perspective, extensive handling operations were performed last week in the Assembly Hall, with two 330-tonne toroidal fields coils transferred from one standing tool to the other.

The displacement operations in the Assembly Hall last week were just the beginning of a giant, slow-motion game of musical chairs. On Monday 23 January and Wednesday 25 January respectively, toroidal field coils TF9 (from Europe) and TF8 (from Japan) were extracted from one of the twin assembly tools (SSAT-1) and moved to the other (SSAT-2). The operation freed the handling tool's wings, which are now ready to receive the thermal shield panels that need to be disassembled from vacuum vessel sector #1(7) in order to be moved to the repair location.

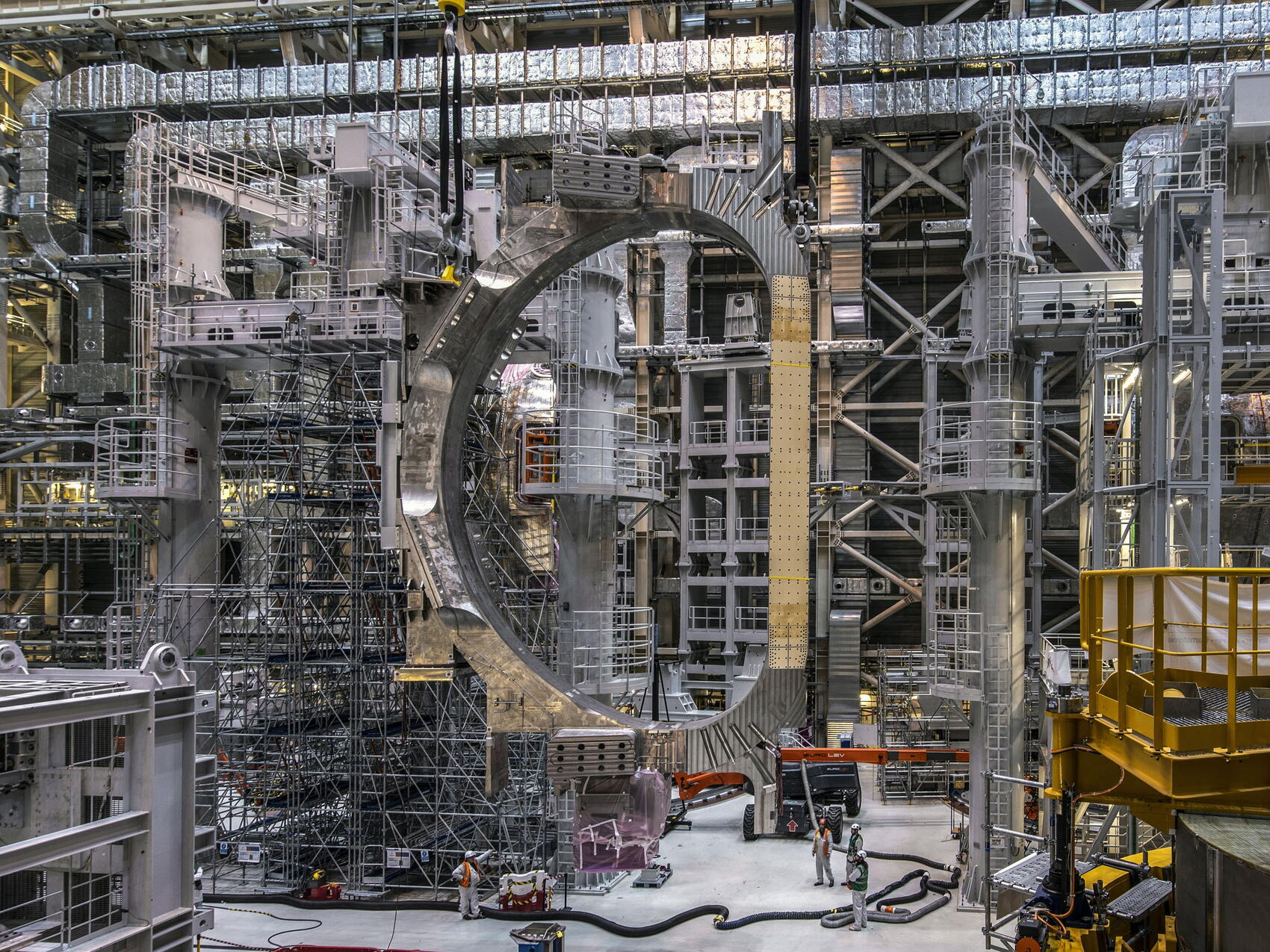

This further disassembly of sector module #1(7) on SSAT-1 should keep the teams busy until the end of March/beginning of April. By then, only the vacuum vessel sector that forms the module's core will remain in the handling tool. At that point, toroidal field coils TF8 and TF9 can be transferred back to the wings of SSAT-1 to free up SSAT-2.

Vacuum vessel sector #8—presently installed in SSAT-2 with no toroidal field coils yet attached—will be extracted and moved to the upending tool. The tool (this time acting as a "down-ending" tool), will move the sector to horizontal so that it can be placed on a transport platform and moved to a repair location.

SSAT-2 will then stand empty ... but not for long.

In late April/early May, a grand and delicate operation will be performed: the lifting of sector module #6 up and out of the tokamak pit, where it had been installed in late May 2022, and its transfer to SSAT-2 for disassembly and repair.

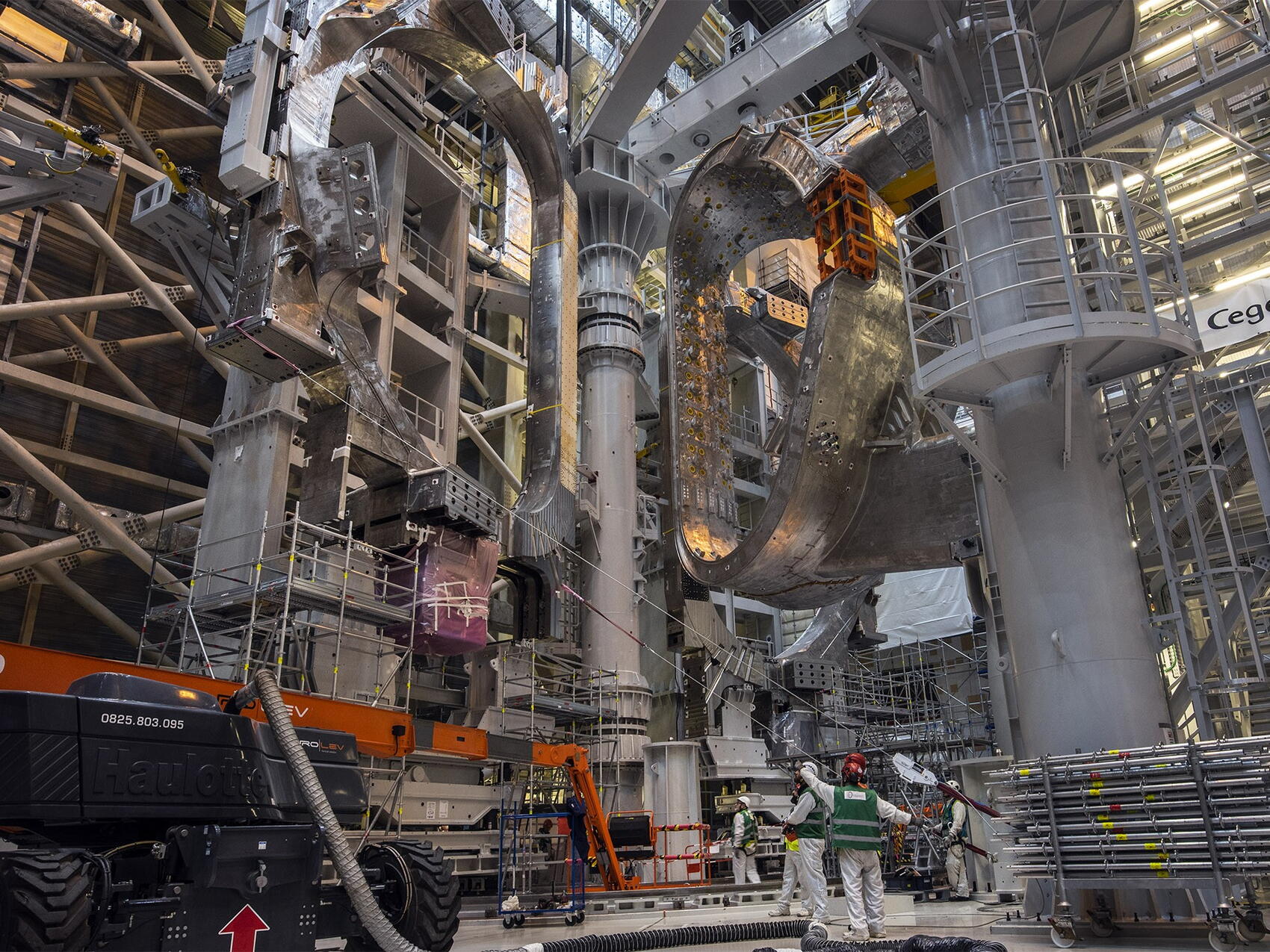

Removing, displacing and disassembling massive components is not just doing things "in reverse" to make them accessible for repairs. These operations require creativity, anticipation and adaptation. Last week's faultless transfer of two 17-metre tall, 330-tonne toroidal field coils demonstrated that the ITER teams were up to the task.