Lightning-power voltage

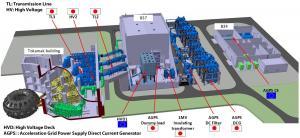

In January 2021, preparatory works began for the construction of two large buildings designed to accommodate a unique set of electrical equipment. A little more than two years later, the main features of the new structures have emerged: steel frames, anchored in massive concrete slabs, rise up to 25 metres; thick walls mark out what looks like oversized horse stalls; and underground passages run deep and wide towards the adjacent Tokamak Complex. Civil works are approximately 40 percent complete: the neutral beam power supply infrastructure should be ready for equipment in about one year.

Neutral beam heating is the workhorse of plasma-heating techniques, injecting high-energy particles into the plasma in order to bring it to the temperature at which fusion reactions can occur. "Basically, a neutral beam injector is an ion accelerator. The speed of the particles, and hence the kinetic energy they can communicate to the plasma, is proportional to the voltage used to accelerate them," explains Hans Decamps, the electrical engineer responsible for the ITER neutral beam power supply.

In the European JET, presently the world's largest operating tokamak, the neutral beam system delivers an electrical voltage on the order of 130,000 volts; in the Euro-Japanese JT-60SA, it will reach 500,000 volts for a few minutes; in ITER, it will need to deliver one million volts (1MV) for durations of up to one hour.

Such ultra-high voltage, sustained for such a long duration, is "outside and beyond anything that's ever been done in terms of electrical engineering," says Decamps. Designing the system has required a full decade of research and development and the construction of full-scale mockups in a dedicated test facility.

The level of the voltage required by the ITER neutral beam injectors has also determined the unusual features of the High Voltage Building—the largest of the two structures under construction, whose available space is equally split into three distinct halls: two devoted to the heating neutral beam injectors, and a third devoted to the diagnostic neutral beam injector (see box).

The twin halls for the heating neutral beam system will be mostly empty, with the exception of two towering, alien-looking components: the 9-metre tall high-voltage deck sitting on its 6-metre tall insulating supports, as well as the even-taller bushing (16 metres) for the giant insulating transformer whose main body sits outside the building. The nature of these one-of-a-kind electrical powerhouses has imposed severe constraints on the building's interior design. To prevent the generation of electrical arcs, no element inside the halls can present a sharp angle or a protruding structure, and for safety reasons each deck is surrounded by a five-metre-radius "exclusion zone." Needless to say, no one will be admitted inside the building during operation.

Inside the recently erected steel structure, the bright yellow beams of two overhead cranes are already in place. These cranes, with the capacity to lift 10 tonnes each, will travel the length of the heating neutral beam high-voltage halls.

Less spectacular but no less strategic, the Neutral Beam Power Supply Building will host the electrical equipment—dry transformers, power convertors, rectifiers, inverters and other exotic devices—that will feed power to the high-voltage decks through the ten step-up transformers installed between the buildings. Like many components in the ITER installation, the neutral beam system operates in DC current. But contrary to the magnets for instance, which demand high current and low voltage, the neutral beam system requires low current and ultra-high voltage.

This difference doesn't make the equipment smaller: procured by Japan, the ten 200 kV DCGs (a step-up transformer connected to a diode tank to obtain 200kV output DC voltage) for the heating neutral beam, each in its own stall separated by thick blast walls, are as large as the giant pulsed power network transformers in the ITER switchyard. Here again, it is the insulation requirements, particularly the quantity of oil that each transformer contains (up to 75,000 litres) that determines the size. Three smaller transformers will be dedicated to the diagnostics neutral beam system.)

Only the raw forces of nature generate voltage higher than that of ITER's neutral beam power supply installation. But lightning strikes are millisecond events, whereas the formidable electrical installation on the ITER site is designed to steadily feed the injectors for hour-long plasma discharges. As such, it has no equivalent in the world.