Taking stock, midway through plant procurement

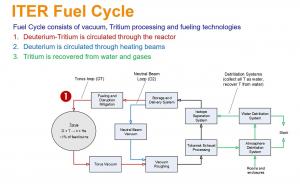

Multiple technologies are involved in the extraction and separation process in the Tritium Plant, grouped into six sub-systems:

* Tokamak Exhaust Processing — receives reactor exhaust and separates out impurities from the hydrogen isotopes. (Procured by the United States.)

* Isotope Separation — receives the purified hydrogen isotope steam and separates deuterium from tritium. (Procured by Europe.)

* Storage and Delivery — stores ITER fuel, whether recycled or new. (Procured by Korea.)

* Atmospheric Detritiation — recovers tritium from impurity gases as water. (Procured by Japan and the ITER Organization.)

* Water Detritiation — recovers tritium from tritiated water and returns it to the fuelling stream. (Procured by Europe.)

* Analytics — chemical and isotopic analysis in support of other five sub-systems. (Procured by the ITER Organization.)

"As contributors to the ITER Tritium Plant work toward the final design of the process systems under their responsibility, we thought the time was right to compare notes, hear about progress and challenges, and discuss ways to save cost and accelerate the project," says Ian Bonnett, head of the Tritium Plant Section. From 5 to 9 June 2023, he organized a Tritium Plant Summit at ITER, with 65 people present on site and several dozen dial-in participants.

"It had been at least 15 years since the last comprehensive meeting on the Tritium Plant. We wanted to gather the procuring agencies together with technical responsible officers for interfacing systems, integration officers, and safety specialists, and bring everyone to the same level of understanding about the status of procurement."

On the first day of the Summit, each procuring agency presented its system design efforts and future milestones, leaving all participants with a broad overview of program status. In 31 breakout sessions throughout the week, the focus was on ways to integrate and mutualize the efforts underway by the different parties. Are there opportunities for standardization that can result in manufacturing savings across multiple packages? Can a common approach to operation and maintenance be adopted so that Tritium Plant tools can be standard? Can a common calibration approach be decided on for process equipment?

"There is a lot of commonality behind the technology of the Tritium Plant systems," says Bonnett. "If one party's qualified solution for a common component like an isolation valve can be standardized, as a project we save money and time."

Working from Tritium Plant status as defined during the Tritium Plant Summit, the next challenge will be to build an integrated schedule that merges the construction and building services milestones in the Tritium Building with process equipment milestones planned by the Domestic Agencies and the ITER Organization. "We hope to have an integrated schedule by the end of this year," says Bonnett. As part of this forward-looking work, the teams will be taking into account the re-baselining work that is underway project wide, and incorporating any changes to the plan for machine operation that emerge as a result.

In the end, the main objective of the Tritium Plant Summit—a shared sense of ownership in the Tritium Plant project—was achieved. A 2024 Summit is planned.

For detailed information about the ITER Tritium Plant, see this recent ITER Talks video.