Final design review for magnet feeders

24 Sep 2010

-

Neil Mitchell, Head of the ITER Magnets Division

The magnet feeder final design review was held in Cadarache this week on 20-22 September. This important milestone marks the conclusion of an intense team effort of the ITER Organization and the Institute of Plasma Physics at the Chinese Academy of Science (ASIPP) to complete the design of the feeders, and opens the door to signing the Procurement Arrangement with the Chinese Domestic Agency.

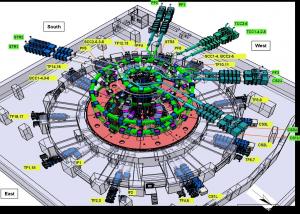

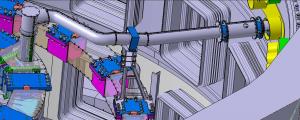

The feeders are the lift-lines to the ITER magnet systems. They convey and regulate the cryogenic liquids to cool and control their temperature. They also connect the magnets to their power supply. The feeders thus represent a critical component interfacing the magnets with other vital parts of the machine.

"The feeders are not as glamorous as the magnets," Chairman Philippe Lebrun said, Project Manager of the Large Hadron Collider at CERN, "but they are vital elements that have many interfaces. They therefore tend to reveal interface issues and that is what is happening right here."

The review was preceded by two pre-reviews, one on the high temperature superconducting (HTS) current leads and one on the assembly of the feeders into the cryostat and the building galleries. The feeders are the final magnet component to go through a final design review and will be the last magnet Procurement Arrangement to be signed. Their completion has been delayed due to the need to focus the very limited magnet division resources onto the magnets themselves, which have longer manufacturing lead times.

On day three, the reviewers presented their overall summary, noting that although a lot of work remains to be done before the Procurement Arrangement can be signed in three months, the foundations have been established and there are no "show stoppers" seen to the successful completion of the Procurement Arrangement documentation on this timescale.