Measuring fusion power

15 Oct 2010

-

Sabina Griffith

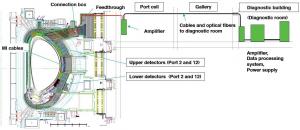

The microfission chamber unit is mounted on the vacuum vessel behind a blanket module. The base plate will be welded to the vacuum vessel, cooled by water coolant, and the plate will be cooled by heat conduction.

The measurement of the neutron emission stemming from the fusion reaction is a very important diagnostic because it is directly related to measuring the fusion power. A typical neutron counter is the fission chamber. This detector, originally developed as a monitor for fission reactors, has been applied for decades on various large fusion devices like JET in Europe, JT60 in Japan and TFTR in USA.

A micro fission chamber is a ionization chamber, i.e., a small cylinder containing argon gas and a tiny amount of uranium (235U). As a neutron hits the uranium, a fission event will be generated and a pulsed signal triggered which can be translated into the amount of power generated. In ITER, the pencil size monitors will be located inside the vacuum vessel behind the blanket modules.

Recently, the conceptual design review for the ITER micro fission chamber, an effort lead by Luciano Bertalot and Anna Encheva, was concluded successfully with no "category 1" chits (no identified showstoppers). "The stringent quality control on ITER design enforced by the conceptual design review panel makes such events rare and highlights the outstanding teamwork within the ITER Project," a relieved Anna Encheva commented the outcome of the two-day review.

Special thanks to Anna Encheva and Luciano Bertalot for their contribution to this article.