Conductor qualification takes a further step forward

26 Nov 2010

-

Alexander Vostner, Superconductor Systems and Auxiliaries Section

Recently, the ITER magnets team together with representatives from the Chinese Domestic Agency (CN-DA) visited the strand supplier Western Superconducting Technologies (WST) in Xi'an in order to review the status of the strand production and assess the readiness for the next production phases. WST has been selected by CN-DA to provide the Nb3Sn strand for the Chinese share of ITER's toroidal field conductors and all NbTi strand for the poloidal field coils numbers two and five, the correction coils, and the feeder conductors. This amounts to about 30 tonnes of Nb3Sn and 150 tonnes of NbTi strand.

Since the beginning of 2009, WST has invested a lot of effort in finalizing the strand designs for the ITER conductors and in implementing a quality assurance system according to high ITER standards. After two days of checking material certificates and work instructions, the representatives of the CN-DA and ITER's Quality Assurance Divisions confirmed that there is full traceability and that the documentation meets the ITER quality assurance requirements.

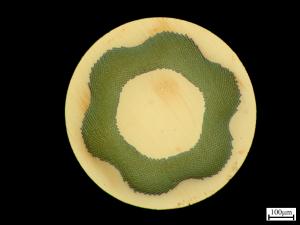

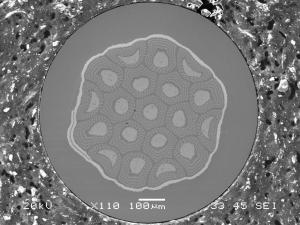

The technical performance of the WST strand is very good as well. The poloidal field conductor performance qualification sample made out of their NbTi strand has successfully passed the test in the Sultan facility this May, and end of October WST qualified their reference Nb3Sn strand for the toroidal field conductor. After reviewing all the data provided, CN-DA and the ITER Organization came to the conclusion that WST is qualified for toroidal field and poloidal field strand production. As a consequence, WST can now launch the second production phase for both strand types.

For CN-DA, this is a significant step forward into the production of ITER conductors as it demonstrates that China has the capability to produce qualified cable-in-conduit conductor (CICC) for ITER. Thanks to the good collaboration with CN-DA and the large R&D program launched, WST has been qualified in time as one of the major strand suppliers for the ITER Project.