Magnet feeders: trial fabrication is well advanced

The pace of progress is accelerating for the ITER magnet feeders. Following the successful completion of the final design review in December and the signature of the Procurement Arrangement in January, the Chinese Domestic Agency (CN-DA) is currently preparing the formal tender process for an industrial supplier.

Since mid-2010, trial hardware fabrication for the ITER feeders has been underway at the Institute of Plasma Physics of the Chinese Academy of Sciences (ASIPP), in parallel with the construction of new fabrication facilities—one of which is complete and being commissioned.

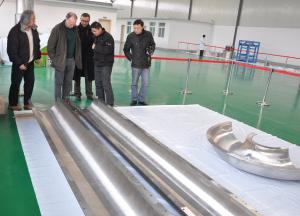

Three members of the Magnet Division at the ITER Organization—Neil Mitchell, Arnaud Devred and Chen-yu Gung—travelled to China in February to view some of the results of these trials, together with Niu Erwu from the CN-DA and Song Yuntao and members of the feeder group from ASIPP, including former ITER Organization member Weng Peide.

The trial fabrication is well advanced and includes cryogenic piping systems, coil terminal boxes, elements of the S-bend box, parts of feeder ducts and the vacuum barrier.

The meeting also focused on the timeline in 2011 for preparing the feeder manufacturing drawings and on the implementation of quality controls in the new facilities and the sub-suppliers, when a contract is awarded.