ITER Codac system—a world language

7 Apr 2011

-

Anders Wallander, Codac Section Leader

In February last year we reported about the release of the ITER "Plant Control Design Handbook" (PCDH), a document that enables all parts of the ITER machine to speak the same language. Since the various parts of the machine are constructed all over the world by the ITER Members, it is fundamental that this "language" be defined, communicated and accepted in advance.

PCDH defines the norms and standards to be applied when developing the control systems for plant systems and is an essential part of ensuring the integration and operation of ITER.

The ITER CODAC Division has now released the 2011 edition of the PCDH after a thorough review involving all ITER Member states. The 2011 edition of PCDH is complemented by a comprehensive set of additional information including examples, recommendation and guidelines to help the user.

See more on the PCDH here.

In parallel to the release of PCDH, a new version of CODAC Core System has been issued. CODAC Core System is the software package that allows the plant system developer to implement and test the local control system. CODAC Core System includes Mini-CODAC, which will be the official tool to execute factory acceptance tests.

See more on the CODAC Core System here.

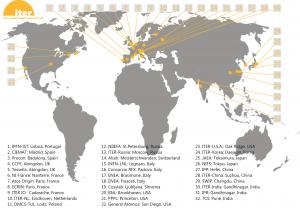

Currently, 32 organizations within the ITER Members have registered for and are using CODAC Core System. This number is expected to grow to more than one hundred when the design and construction of plant systems takes off in the next years.

Various pilot projects are currently performed to apply both PCDH and CODAC Core System on real systems. For example, the B20/B21 substations providing power to the ITER site will be interfaced and monitored by CODAC. The flywheel generator at the FSU Tokamak in Frascati, Italy is at present under conversion to a fully compliant ITER plant system, as is the fuelling system at KSTAR in Korea. The ITER CODAC system is truly becoming a world language.