Europe advances cabling and jacketing activities

20 May 2011

-

Thierry Boutboul, European Domestic Agency

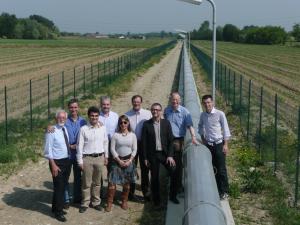

ITER representatives, together with ENEA and EU-DA staff, visiting the recently completed 800-metre-long jacketing line at Criotec.

On 11-12 May, ITER representatives visited the cable manufacture and jacketing facilities in Italy that are under contract with the European Domestic Agency to provide part of the completed conductors for ITER's toroidal and poloidal field magnet systems.

The European contribution to the conductors of the ITER magnet systems represents approximately 20 percent of the entire amount of the toroidal field conductor lengths and 12 percent of the poloidal field lengths.

"It is important to develop a good working relationship with suppliers and the Domestic Agencies through regular visits, especially during the critical early stages of set-up and qualification," states Neil Mitchell, Head of the ITER Magnet Division. "This is the best way to ensure that ITER quality needs are met and it also allows informal discussions on flexibility—especially for cost saving and schedule optimization purposes—that are much more effective than formal meetings."

Following an international call for tender, the Italian Consortium for Applied Superconductivity (ICAS) was chosen by the European Domestic Agency (EU-DA) in 2010 for the cabling and jacketing of approximately 20 km of ITER toroidal field conductor and the jacketing of about 22 km of ITER poloidal field conductor. In addition to cabling and jacketing, ICAS is also charged with the procurement of the stainless steel tubes, wraps and central spirals required for the conductors. The ICAS consortium is composed of ENEA (Frascati, Italy) in charge of general project management, scheduling, administration and quality assurance; Tratos Cavi S.p.A. (Pieve Santo Stefano, Italy) for cable manufacture; and Criotec Impianti S.r.l. (Chivasso, Italy) for jacketing and the completion of the unit conductor lengths.

The EU-DA will supply toroidal field copper and niobium-tin (Nb3Sn) strands to the consortium for cabling and jacketing. The poloidal field cable lengths will be supplied by the Russian Domestic Agency (RF-DA) according to a Procurement Implementation Agreement signed between Europe and Russia that stipulates that the RF-DA will manufacture the niobium-titanium (NbTi) superconducting strand and cables for both the Russian and European poloidal field conductor lengths, while the EU-DA will jacket both the Russian and European poloidal field cables.

Overall, the EU-DA has the responsibility for the jacketing of more than 30 percent of the total amount of poloidal field conductor lengths needed for the ITER Project.

Since the contract signature, ICAS has begun very intense activity to design and build the machines and the tooling necessary for the contract and to launch the procurement of stainless steel jacket sections and other components. In particular, the jacketing line, an 800-metre-long line where the jacket is assembled and the cable inserted into the jacket, has been very recently completed at Criotec. In addition, a new cabling machine for the cabling of the poloidal field jacket round-in-square tubes has been developed and built and is currently under qualification. For the cabling at Tratos, the three cabling machines needed for the five-stage cabling process are already operational and the first cabling trials have begun. The cabling of the ITER toroidal field copper dummy cable length is foreseen to start in June.