Pre-compression rings to last longer than ITER

2 Sep 2011

-

Juan Knaster, Technical Officer, TF coils and pre-compression rings

The pre-compression rings of the ITER magnet system will tightly hold the toroidal field coils on top and bottom with a radial force of 7,000 tonnes per coil. The most suitable material to withstand such high loads and avoid circulation of currents during machine operation is glass-fiber/epoxy composite.

Most metals at the stresses generated in the composite of the rings would break. And yet the role of the pre-compression rings is essential, since in their absence the ITER toroidal field coils would fail by fatigue before the 30,000 plasma pulses expected during their design life of 20 years.

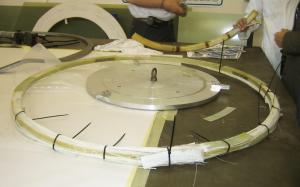

The ITER pre-compression rings are possibly the most massive composite structures ever attempted. More than one decade of thorough R&D work at ENEA (Frascati) managed to overcome all the initial technical challenges.

At ENEA, a purpose-designed machine stressed model pre-compression rings to test their strength and observed a rupture point at approximately four times the expected operational stresses of ITER.

Graph showing the breaking time in hours for different percentages of the long-term breaking stress divided by the known average rupture stress (UTS) for specimens, in black, and model rings, in red. The points with an arrow indicate that the element tested was removed from the testing equipment unbroken.

However, the possibility of degradation over time (creep) was a concern. The team established a curve describing long-term performance of the rings' material with small test specimens continuously loaded at different stresses over a span of three years.

ENEA's purpose-designed machine was then used to assess the long-term behaviour of the rings. Due to the non-linear behaviour and different material properties along different directions of composites, a correlation between tested specimens and model rings was difficult to establish, since the model rings could only withstand stresses of around 70 percent of those observed for small specimens.

However, an intelligent handling of the available data carried out by the team of Paolo Rossi at ENEA by plotting together the percentage of the breaking point of the long-term tests of small specimens and model rings over the known rupture stress, shows a correlation that predicts that the rings under ITER's operational stresses (<30 percent of the rings' measured and specified breaking point) would maintain their tension for many years, much more than the life of ITER.