The challenging design of ITER's cooling water system

13 Apr 2012

-

Sabina Griffith

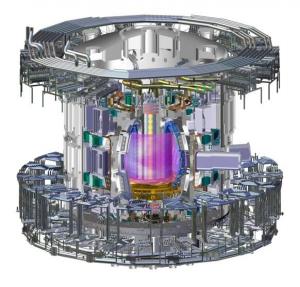

The design of ITER's cooling water system is maturing. The system, consisting of the tokamak cooling water system (TCWS), the component cooling water system (CCWS), the chilled water system (CHWS) and the heat rejection system (HRS), is responsible for removing the enormous amounts of heat generated by the tokamak and its auxiliary systems, with an anticipated peak heat load of more than 1100 MW.

Over the course of the past year, some impressive progress has been made on many pending issues enabling the teams to take the design of these crucial components from their conceptual design to the next level. The formal preliminary design review for the tokamak cooling water system was completed last month on 20-22 March in Cadarache with more than 20 participants from the US Domestic Agency and its contractor AREVA Federal Services LLC. The following week, the expert group for the heat rejection system, another essential part of ITER's cooling system that is supplied by the Indian Domestic Agency, moved in.

The TCWS preliminary design improved the operation and safety of the primary thermal management system. Pathways for the discharge of radioactively contaminated water to the environment were eliminated. Four separate cooling systems for the first wall/blanket and divertor were combined into a single system to improve operational flexibility and system availability. Significant progress was reported on the design of supporting systems such as the chemical and volume control, drying, and draining. "In fact, the TCWS design is now 65 percent complete and is documented in 116 reports and drawings, a comprehensive 3D Design Model with 56 work packages, and 44 interface sheets," states Jan Berry, US team leader of the Tokamak Cooling Water System.

At this phase of TCWS design development, the expertise and advice from the power producing industry is crucial as the ITER Organization/US Domestic Agency/industry team comprised of more than 100 engineers and designers is responsible for developing the final design and ultimately the fabrication and delivery of the components.

"AREVA has designed and built many cooling water systems for reactors," Joe Stringer, vice president at AREVA Federal Services LLC replied when asked about the challenges the full-service nuclear provider faces working on the ITER fusion reactor. "However there are design features for the ITER Project which make the design solution unique. The TCWS has more interfaces with other design organizations than any other system and at the same time the project requires completion of the design and delivery of the piping and components on a very aggressive schedule. But AREVA is very proud to be part of the ITER team and we are committed to meeting the significant challenges ahead."

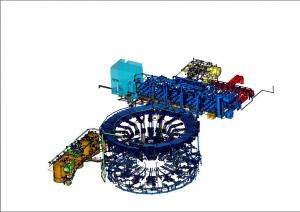

For the team in charge of HRS design the cyclic nature of the ITER machine presented the most distinct challenge. "The HRS must reject normal facility heat loads plus large intermittent heat loads from the pulsed operations of the tokamak while maintaining stable and predictable cooling water basin temperatures to meet the needs of the cooling water system clients," explains Steve Ployhar, responsible officer for the heat rejection system. "It would have been easy to size the cooling towers based on peak conditions, but this solution would have been unacceptable in regards to the use of resources, both in terms of capital cost and space on the site."

ITER's complex cooling water system has to remove an anticipated initial peak heat load of more than 1100 MW.

The challenge for the design team was therefore to meet the heat rejection needs while minimizing the cost and the footprint of the cooling towers. Part of the solution proposed by the Indian Domestic Agency involves the construction of an additional hot basin and associated pumps to absorb the hot water generated during the "burn" phase of the plasma pulse and discharge it to the cooling tower at a constant rate throughout the plasma pulse cycle, thus making more efficient use of the cooling towers. This solution will guarantee the reliability of the system and will keep the additional footprint to 50 percent of what would have been required otherwise.

"The cooling water systems interface with virtually all ITER systems and facilities and their successful design involves coordination as well as technical challenges. The outcome of the preliminary design reviews for TCWS and HRS give us confidence that these challenges are being met," concludes Giovanni Dell Orco, leader of the ITER Cooling Water System Section.

"The cooling water systems interface with virtually all ITER systems and facilities and their successful design involves coordination as well as technical challenges. The outcome of the preliminary design reviews for TCWS and HRS give us confidence that these challenges are being met," concludes Giovanni Dell Orco, leader of the ITER Cooling Water System Section.

Sekhar Basu, chief executive at the Department of Atomic Energy in India and chairman of the Design Review, also expressed his confidence that the design for the ITER's heat rejection system provided enough flexibility for the varying load conditions. "We will resolve the remaining interface and environmental issues for this system judiciously in order to allow the project to move forward in a time- and cost-effective manner."