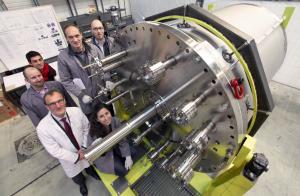

Last week, members of the ITER Vacuum Section travelled to Tarbes, in southwestern France, where Alsyom had just finalized the casing for the pump. The team wanted to make sure that there were no issues before the 8-tonne, 3-metre cylinder is sent to Germany to be equipped with its internal cryogenic circuits.

"The torus cryopumps are large, complex, high-precision components that will be exposed to huge temperature gradients in a very punishing environment," says Section Leader Robert Pearce. "Integrated in the pumps is the world's largest all-metal high-vacuum valve and it was an extraordinary accomplishment that our contractors were able to achieve 80-micron tolerances over such a large component with heavy welding."

The pre-production torus cryopump will now travel to Germany, where specialists at Research Instruments will install its inner components—cryogenic surfaces, charcoal-coated panels and protective thermal screens. Once finalized and leak-tested, it will be characterized on a test facility and is likely to be the first pump to be installed on ITER.