New building, two purposes

Excavation has started for a concrete building designed for the distinct storage and handling requirements of ITER's beryllium components—in particular, the first-wall panels of the ITER blanket. But as these components are not expected on site before late 2024, the building will be used in the interim for Tokamak pre-assembly work.

The first-wall panels of the ITER blanket—which will face heat fluxes of up to 4.7 MW/m²—will be armoured with beryllium, a metal chosen for its high melting point and its low atomic number (minimal impact on plasma performance). The 460 plasma-facing first wall panels will require about 12 tonnes of beryllium to cover a surface of 610 m².

In the original plans, the receipt and trial fitting activities of first-wall panels were to take place in the ITER Hot Cell Complex. Changes related to the staged approach to ITER construction, however, now mean that the Hot Cell Complex will only become available at the end of 2028.

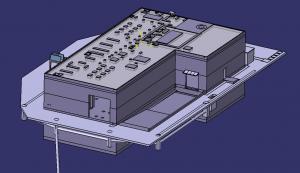

The 1600 m² building will be a one-storey structure with a full basement, unloading dock and lifting platform. A 250 m² mezzanine will be added in TAPB Phase-2, to provide for the HVAC equipment necessary to house beryllium in the facility.

- In-vessel mockups and trials: a space for assembly mockups to permit the training and qualification of procedures, processes and operators.

- Vacuum laboratory support: spill-over space for the site acceptance tests, maintenance, or storage of vacuum components.

- Magnet infrastructure facilities for ITER: space to receive, inspect, test and, if necessary, repair large magnet components; magnet assembly mockups for training and qualification purposes.

The control of the beryllium risk must comply with the requirements of French Decree No. 2012-1248 of 9 November 2012. The key safety function of the TAPB building is therefore the confinement of beryllium in order to protect the workers, the public and the environment (by providing static and dynamic confinement).

Design work began two years ago; now, construction has started on site. The building is expected to be completed in the summer of 2020, just as the first major machine assembly activities are getting underway in the Tokamak Building.