Atterissage en douceur

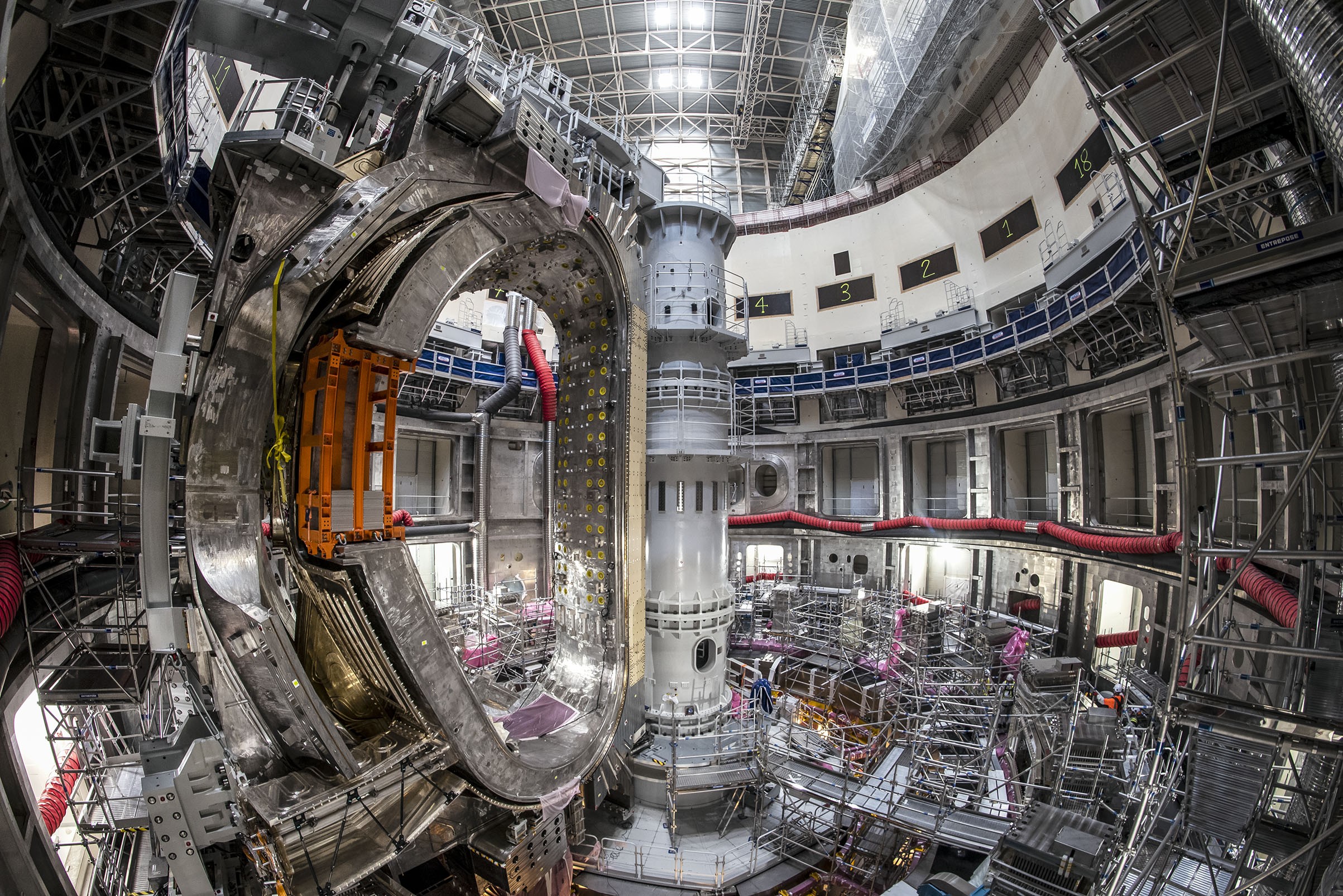

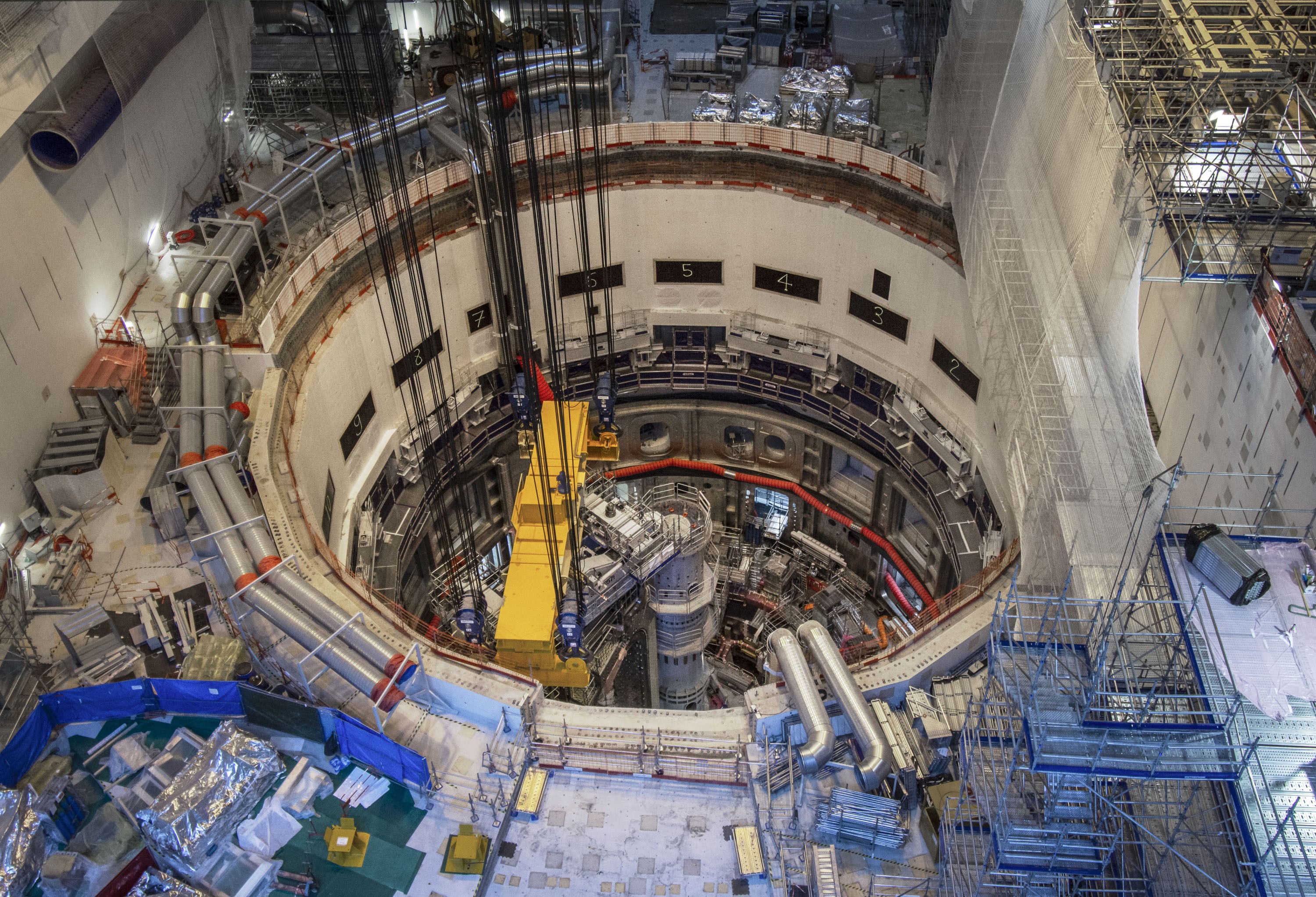

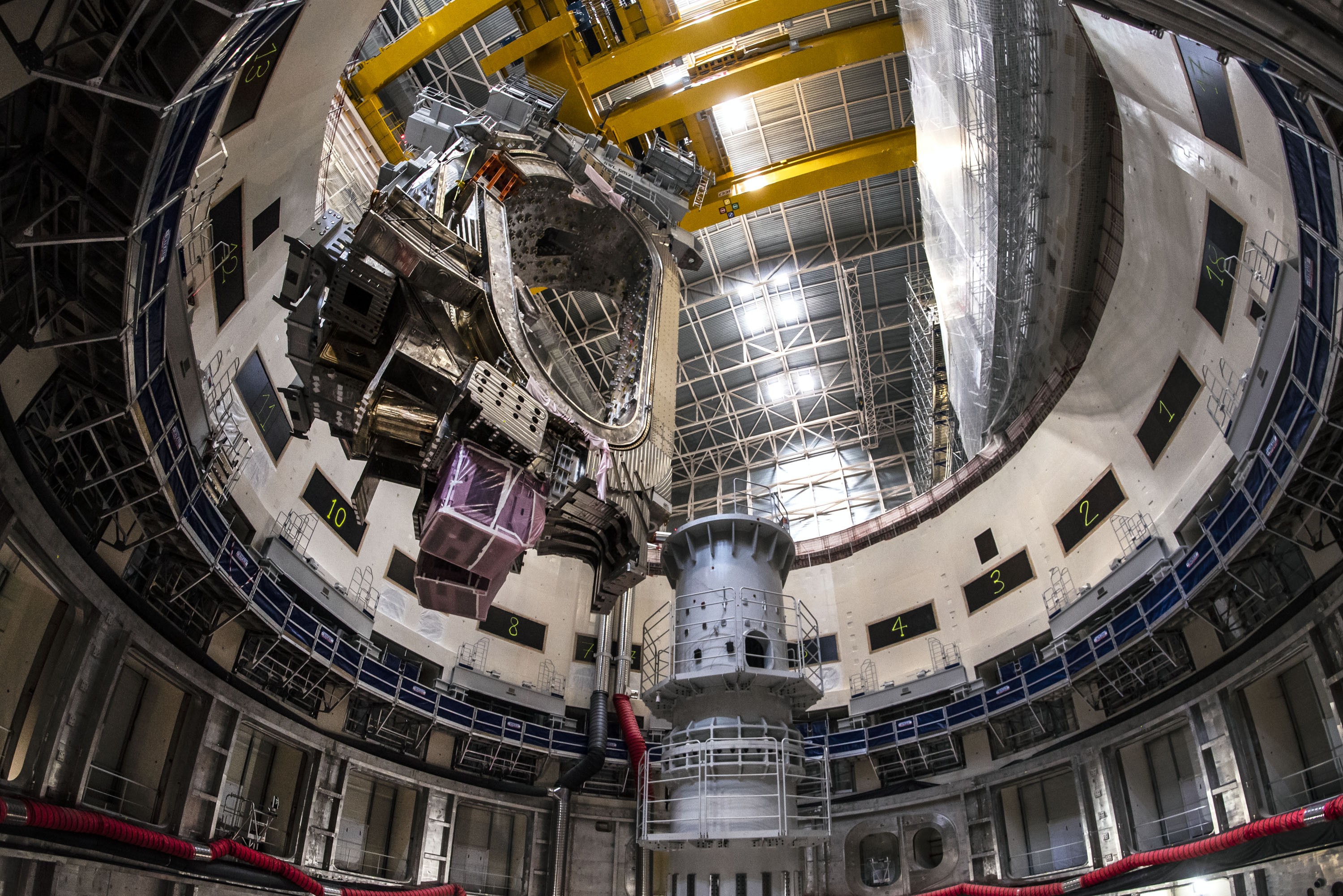

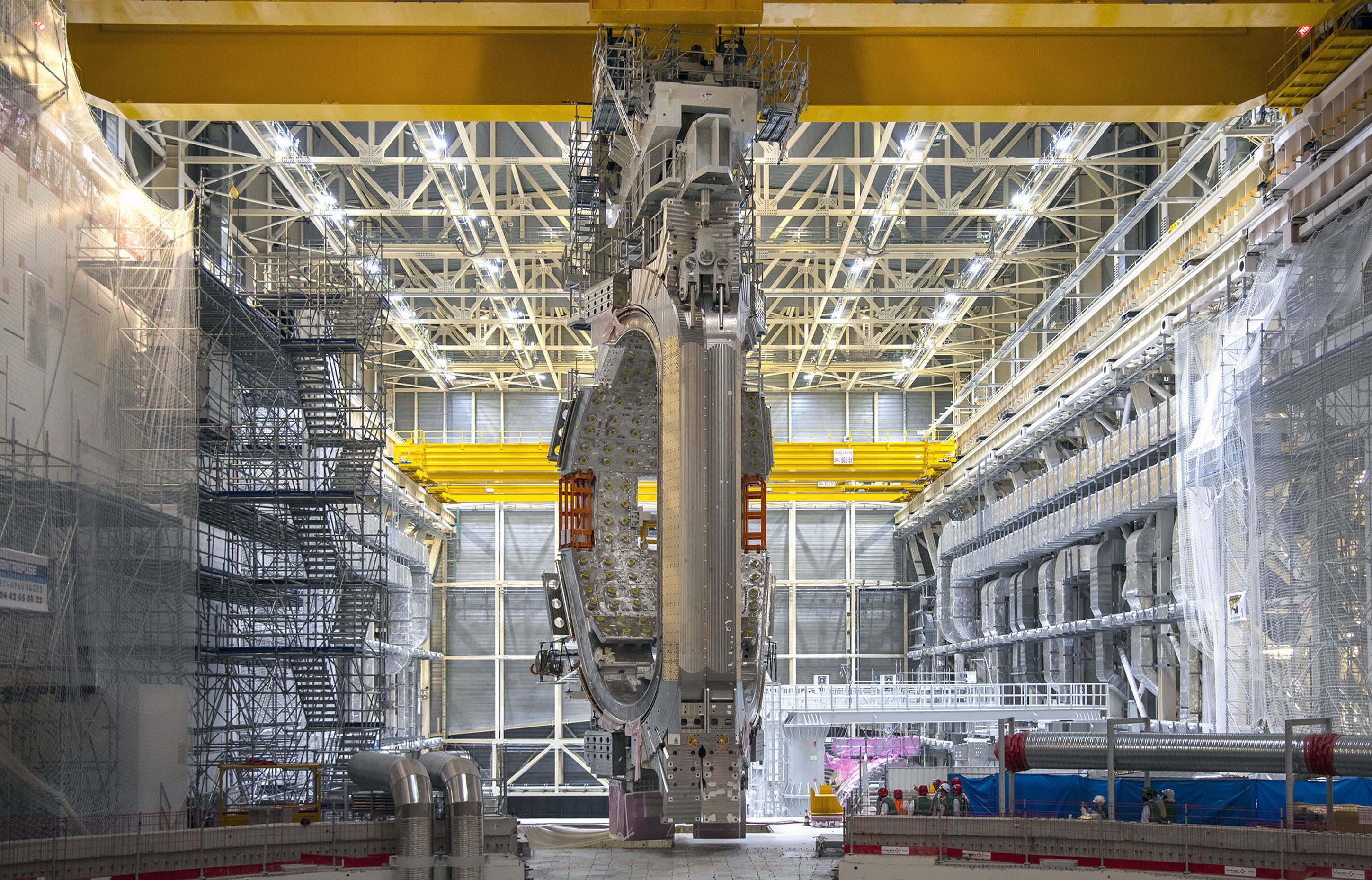

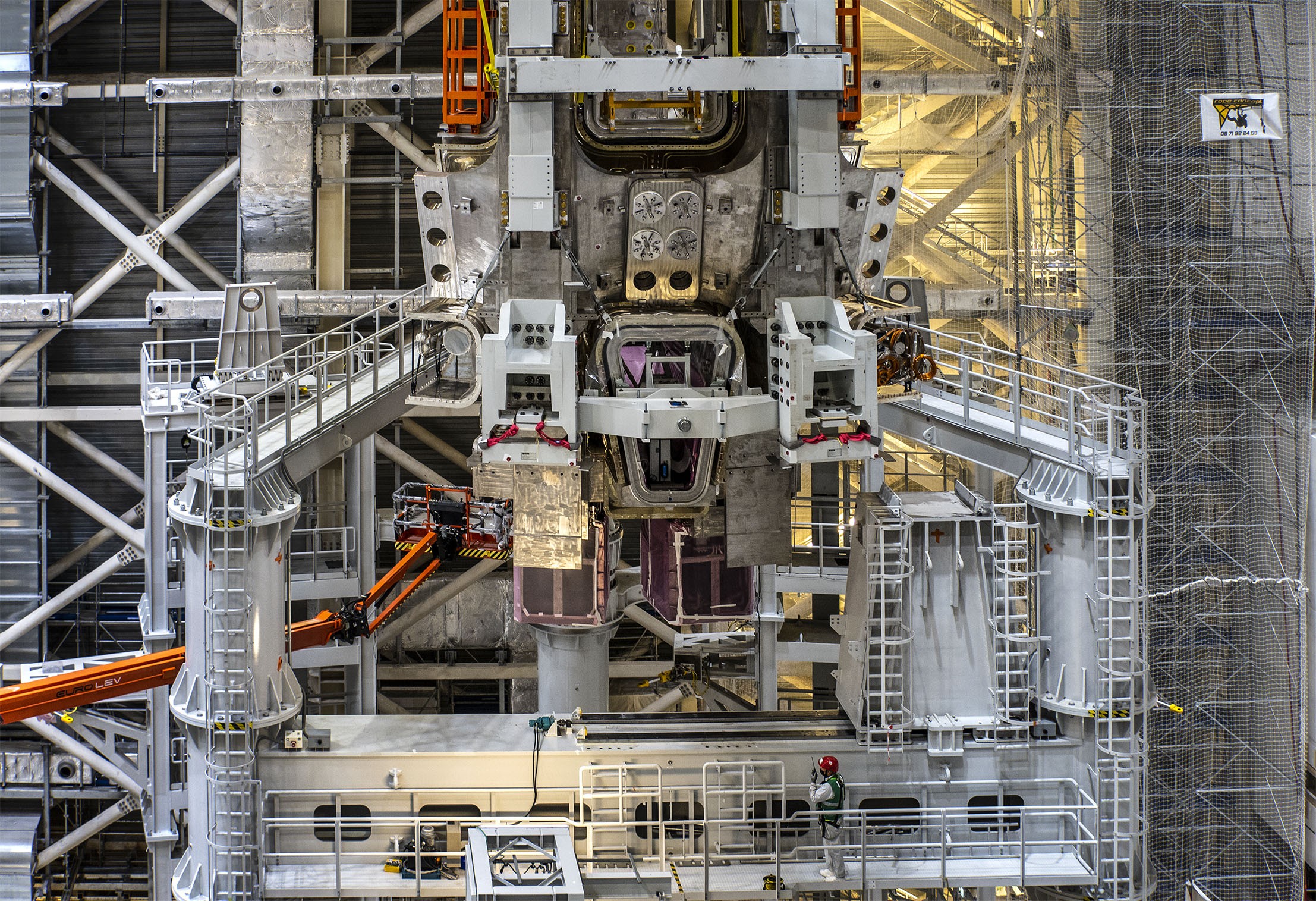

Le « module » n'a pas été conçu pour se poser sur la lune. Il s'agit néanmoins d'une réalisation technologique complexe, dont le maniement exige autant de précision que celui des fameux « modules lunaires » du projet Apollo, entrés dans l'histoire il y a plus de 50 ans. Dans l'univers d'ITER, un « module » est un assemblage composé d'un secteur de chambre à vide, de deux bobines verticales en forme de « D » et des panneaux de bouclier thermique associés, sans oublier les divers équipements annexes et tuyauteries qui portent la masse totale de ce sous-composant à 1 380 tonnes, soit l'équivalent de quatre Boeing 747 à pleine charge. Les 11 et 12 mai, le premier des neuf modules qui constitueront la chambre à vide torique du tokamak a été lentement dégagé du portique de sous-assemblage, soulevé et transporté par-dessus la paroi qui sépare le hall de montage de la fosse d'assemblage de la machine, puis positionné sur ses supports avec une précision submillimétrique. Depuis mai 2020, de nombreuses opérations spectaculaires ont été réalisées dans le cadre de l'assemblage de la machine, mais le processus de levage et de descente de ce premier module de secteur les a toutes éclipsées. Il s'agissait d'une performance extraordinaire et d'une démonstration de maîtrise technologique tout à fait exceptionnelle.

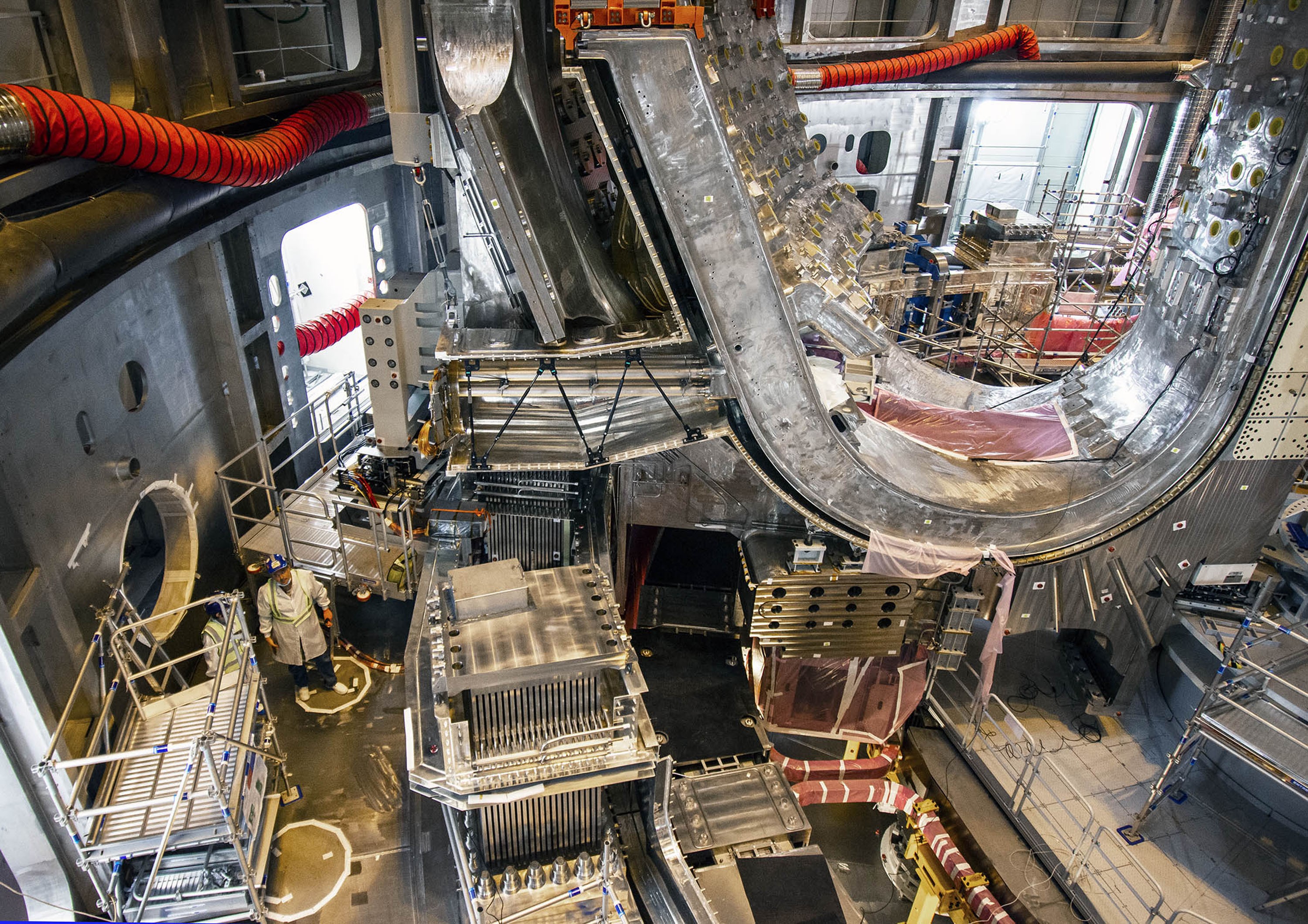

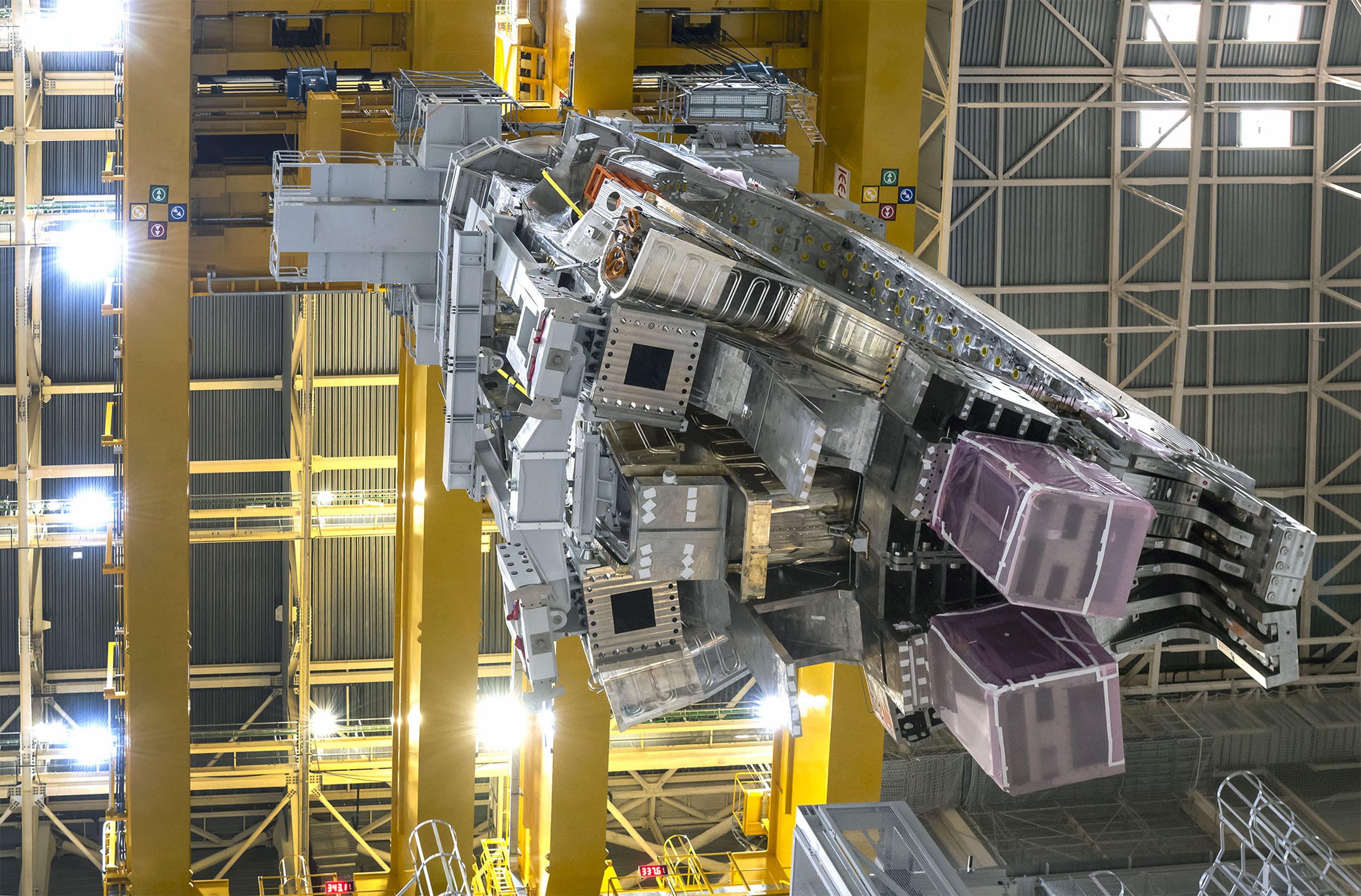

Il a fallu plus d'une année pour planifier cette opération prévue de longue date. Cette manœuvre fut une véritable épreuve du feu en termes de limites de la structure du bâtiment, de capacité de levage du pont roulant, de maniabilité du câblage complexe utilisé et, surtout, de coordination de l'équipe, qui réunissait 50 personnes travaillant pour une demi-douzaine d'entreprises et d'organisations différentes. À chaque étape de la progression du composant, du portique de pré-assemblage jusqu'à son emplacement définitif dans la fosse d'assemblage, un jeu très réduit a été maintenu. Le spectacle de cette charge colossale frôlant les différentes structures présentes sur son passage pour parvenir à sa destination finale était extraordinaire. Quatre centimètres de jeu latéral durant l'opération de dégagement du portique de sous-assemblage, 20 centimètres verticalement lors du passage au-dessus de la paroi de la fosse, 7 centimètres pendant la descente...

Pour prendre en compte l'inévitable « balancement » créé par l'effet pendulaire, le jeu a été minimisé tout au long de l'opération, avec 5 centimètres à peine dans certaines positions.

En raison de la nature composite de la charge, l'un des principaux défis était de déterminer son centre de gravité, un paramètre essentiel pour garantir la sécurité et la fluidité de l'opération de transfert. « Il y avait en réalité deux charges en une, chacune possédant son propre centre de gravité », explique Daniel Coelho, l'ingénieur d'ITER en charge de l'assemblage qui a coordonné les manœuvres de levage. « Bien avant le début de l'opération, alors que le module se trouvait encore dans le portique de pré-assemblage, nous avons caractérisé ses dimensions et son poids avec précision et réalisé des calculs et des modèles 3D afin de définir des objectifs d'alignement théoriques. Mais ces données théoriques n'étaient qu'un point de départ. Nous n'avions aucune certitude absolue avant de commencer le levage, c'est pourquoi l'opération de pré-levage réalisée quelques jours plus tôt était si importante. »

Comme Daniel Coelho, tous les opérateurs présents possédaient une expérience du levage de précision de charges lourdes dans des environnements exigeants, le plus souvent nucléaires. « La différence aujourd'hui, c'est qu'il s'agit d'un contexte inédit. Nous sommes soumis aux contraintes de qualité du secteur nucléaire, mais avec des composants très spécifiques et des jeux extrêmement faibles qui exigent des équipements, des techniques et des procédures de levage exceptionnels. » Comment sont-ils parvenus à relever cet incroyable défi ? « Pour compenser les incertitudes, nous avons utilisé des calculs et des modèles très pointus, des opérateurs hautement qualifiés et des mesures de sécurité exceptionnelles », explique Daniel Coelho dans un sourire.

Mais le succès d'une telle opération ne dépend pas uniquement de la technologie. Les femmes et les hommes qui ont travaillé de manière parfaitement coordonnée au sein de l'équipe que Daniel Coelho qualifie de « famille » ont joué un rôle clé dans sa réussite. « Les sous-traitants s'étaient extrêmement bien préparés pour chaque intervention et ils se sont parfaitement intégrés aux équipes d'ITER Organization. »

À la fin de la journée du mercredi 11 mai, le module, toujours maintenu par son câblage, flottait quelques centimètres au-dessus de ses supports. Dès le lendemain, après quelques mesures supplémentaires et des ajustements minutieux, le module de secteur était arrimé solidement et avec précision dans sa position quasi-finale. À l'intérieur de la fosse d'assemblage, la vue était saisissante. Bien qu'il ne représente qu'un neuvième de la chambre à vide torique, le composant écrasait tout autour de lui par ses proportions.

L'opération a été coordonnée par l'équipe Construction d'ITER Organization et son maître d'ouvrage MOMENTUM, et exécutée par le sous-traitant chargé de l'assemblage du tokamak, DYNAMIC SNC (Ansaldo Nucleare, Endel Engie, Orys Groupe ORTEC, SIMIC, Ansaldo Energia et Leading Metal Mechanic Solutions SL), l'exploitant du pont roulant, Foselev, et les métrologues de GEATOP, avec le soutien des experts en santé et sécurité de l'APAVE.

Consultez le communiqué de presse en anglais ou en français.

Découvrez la vidéo ici.