Cold boxes 20 years in the making

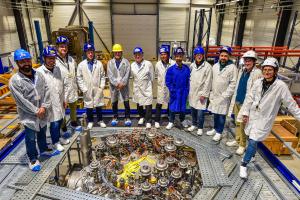

Twenty years—that is how long it took to design, manufacture and deliver the cold valve boxes that regulate the flow of cryogens to the tokamak's vacuum system. Last week, as the first of the eight first-of-a-kind components was undergoing site acceptance testing, the ITER vacuum team organized a "pat on the back" moment to celebrate the completion of this unique conceptual and industrial adventure.

Procured by Europe, manufactured by Research Instruments (Germany) and its subcontractor Cryoworld (Netherlands), the eight cold valve boxes are 4-tonne components measuring more than 3 metres in height and approximately 2 metres in diameter. Each one is equipped with 25 cryogenic valves, relief systems, and pressure and temperature sensors that are specifically designed to operate under the harsh ITER environment. Located in the lower port cells, six boxes are destined for the torus cryopumps and two for the cryostat.

The functional tests presently performed in the ITER vacuum lab will be followed by cold tests at liquid nitrogen temperature (80K, minus 196 °C). An installation is being prepared in the cryoplant to test at 4K.