Twin giants to pre-assemble the vacuum vessel sectors

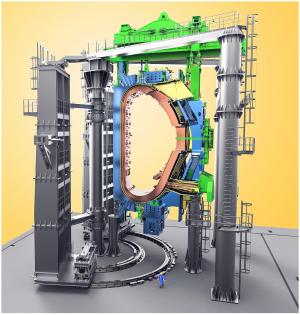

As the doors of the Assembly Building open to admit the first vacuum vessel sectors shipped from manufacturing sites in Europe or Korea, two imposing custom-built tools will stand ready to receive them. Six storeys high, with wings spreading 20 metres, the sector sub-assembly tools will work side by side to equip the nine sectors of the vacuum vessel before their transfer to the tokamak pit, where they will be welded together to form the torus-shaped ITER vacuum chamber.

"It's far from a simple operation," says Emma Watson, an engineer who works within the Machine Assembly & Installation Section at ITER. "For each of the nine sectors, the complete sub-assembly operation will take five to six months." To optimize the overall schedule for the nine sectors, two identical tools are planned, each one capable of holding a sector on its end while positioning—and aligning—the associated components.

The sectors, which will travel from the factories in a horizontal position, will first have to be "upended" by a dedicated tool that is designed to lift the 440-tonne (max) vacuum vessel sectors (7.6 x 6.5 x 13.7 metres) and the 310-tonne toroidal field coils (9 x 3.7 x 17 metres) into their final, vertical orientation.

Late October, at ITER Headquarters, a design integration review was held for a sub-group of 23 tools, including the sector sub-assembly tool, in order to assess design progress prior to the final design review planned for December.