A perfect 10

Vacuum vessel sector #4 has been rotated to its other side in a gold medal outdoor performance.

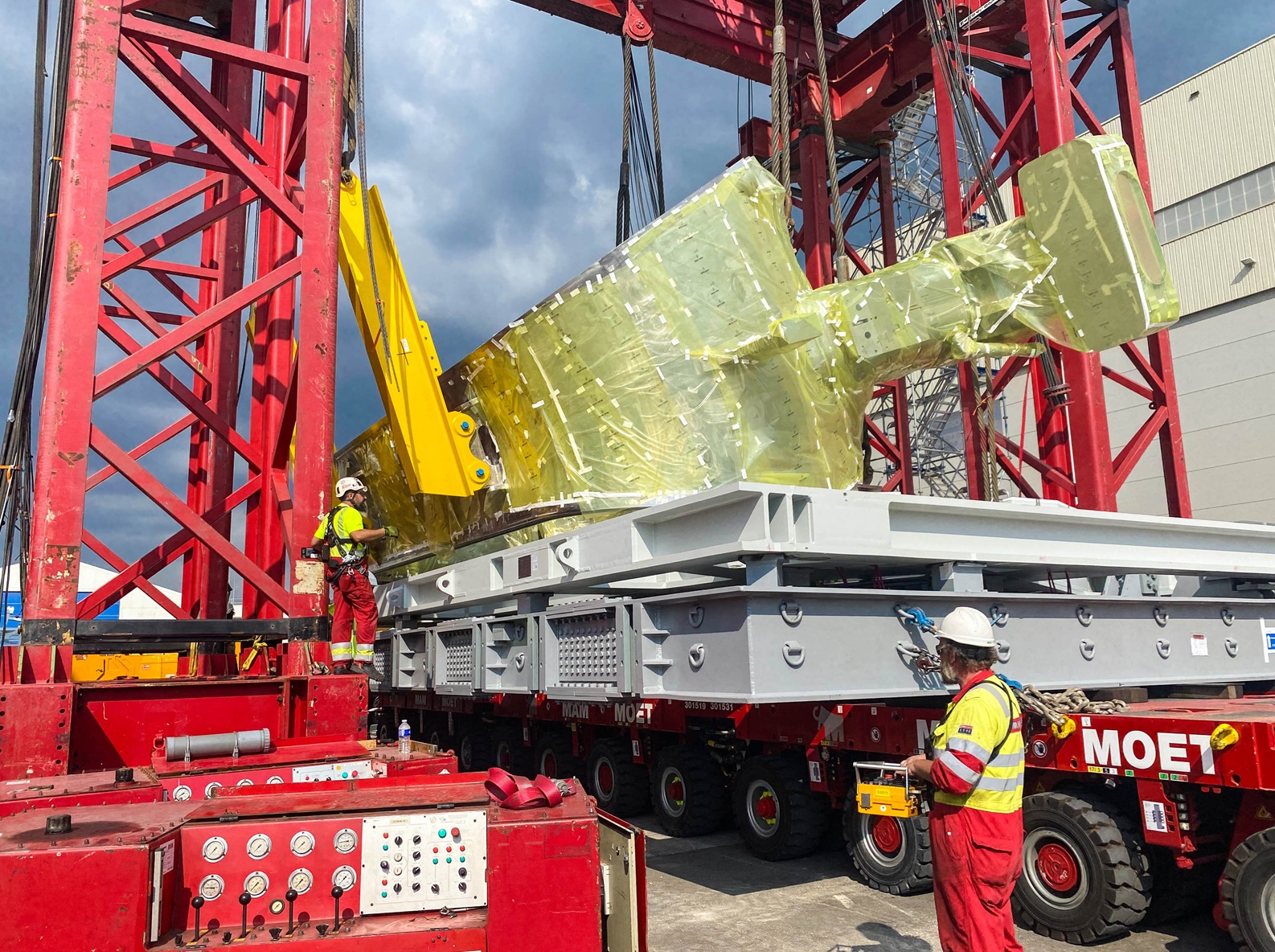

In an unprecedented operation that saved assembly time and eased congestion in the Assembly Hall and tokamak pit, vacuum vessel sector #4 has been successfully rotated by a huge gantry crane outdoors so repairs could be made to its inaccessible side.

With onlookers gathering throughout the 11-hour operation, the 378-tonne sector (nominal delivery weight) was raised into the air on a giant gantry on Tuesday 17 June, where it then performed a slow but spectacular gymnastics-like manoeuvre. “It was exceptional to watch,” says Donato Lioce, ITER’s deputy Tokamak Program manager who oversaw the rotation. “We moved from a concept on a PowerPoint to a first-of-its-kind operation in just two months and it’s thanks to the whole team that this was a success.”

Over the past year, there have been ongoing repairs to the vacuum vessel sectors to even out faulty sections of interface surfaces (bevels) where they will be welded together. For the vacuum vessel sectors being repaired in a horizontal orientation, once one side is repaired the sectors need to be flipped so the work can be done on the other side. For vacuum vessel sector #8, this flipping was executed using the upending tool and a roundtrip voyage into the tokamak pit.

However, because of the limited space in the tokamak pit and the high demand for time on the upending tool, an audacious plan was devised in April 2025 to rotate vacuum vessel sector #4 outdoors. This promised to save about three weeks on the baseline schedule by bypassing the wait for the upending tool while also eliminating a bottleneck in the assembly arena and giving ITER valuable experience with an alternative method for rotating vacuum vessel sectors.

In close collaboration with Mammoet, the company that provided the massive gantry and logistics support, the vacuum vessel team engineered the rotation over the past two months to ensure it could be performed without risk to the component while meeting the most stringent safety conditions. With technicians from the European consortium that had manufactured the sector, six temporary lifting lugs were welded onto the sector so it could be attached to the gantry while two lifting beams were manufactured to serve as braces during the most taxing parts of the procedure.

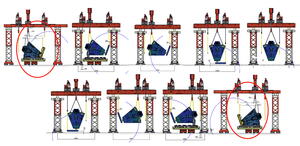

The outdoor rotation plan was developed by ITER engineer Alex Martin and as he did the modelling, he noticed that the planned movements resembled what he had seen during an Olympic gymnastics competition. Sure enough, vacuum vessel sector #4 would be performing an Amanar vault on the gantry, one of the most challenging moves in women’s gymnastics. And, just like with Olympic gymnastics, the landing was essential as the vacuum vessel sector had to come gently down on supporting blocks with a margin of only a few millimeters for error.

“The entire routine went smoothly and we hit our landing,” says Alex Martin. “We can proudly say we performed like Olympic champs.”

Vacuum vessel sector #4 has now been moved back into the former Cryostat Workshop, where the temporary lifting lugs will be removed and repairs on the bevels will be finished. With the first operation a success, the team is now scheduled to rotate vacuum vessel section #1 outdoors at the end of June 2025.