"Low-voltage" review opens way to contracts

17 Dec 2012

The panel that reviewed the low-voltage components was chaired by Michel Huguet, former head of the ITER Joint Work Site at Naka (Japan).

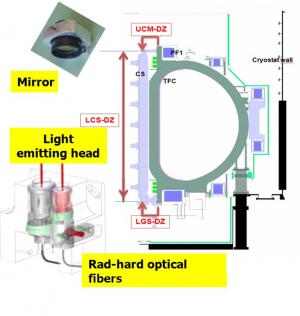

Coil instrumentation in ITER consists of some 3,000 sensors whose function is to monitor the essential parameters of magnets during ITER operation.

A EUR 25 million package, coil instrumentation forms one the few direct purchases of the ITER Organization and the only fund procurement of the Magnet Division. The components will be delivered by the ITER Organization to the Domestic Agencies involved in coil procurement.

Cryogenic and mechanical instrumentation components ("low-voltage" components) account for about one-third of the package's value. Measuring temperature, displacement, strain and deformation, the low-voltage sensors are critical. The Head of the Magnet Division, Neil Mitchell, explains: "These components cannot be maintained once they are installed. If one fails, it is lost. Of course there are redundancies, but we have to do our best to guarantee they will operate for 30 years in the harsh cryostat environment."

A Laser Distance Meter (LDM) to measure the height of the central solenoid stack. The device was adapted for use in cryo-vacuum and noisy electromagnetic and radiation environment (resolution: ≤ 0.3 mm, accuracy: ≤ 1.5 mm).

On 13-14 December, all of the low-voltage components were reviewed by a panel that included members of the different ITER departments and directorates, specialists from the Domestic Agencies, and also internationally reputed external experts.

This was the third Manufacturing Readiness Review organized by the ITER Magnets Division over the last two months. The first one was conducted on the safety class quench detection system on 23 October; the second on 29-30 November for investment protection quench detection and related high voltage components.

All three reviews were capably organised and run by Felix Rodriguez-Mateos, the Technical Responsible Officer for the magnet instrumentation, and his colleagues in the team.

Last week's low-voltage review panel was chaired by Michel Huguet, a major figure in the history of the ITER Project who joined fusion research in 1969 at CEA, spent 19 years at JET, and eventually headed the ITER Joint Work Site at Naka (Japan).

"The panel members were quite satisfied—I could even say impressed—by the quality of the work accomplished. Processes and strategies appear to be heading in the right direction."

Now that the results of the qualification tests have been reviewed (ITER uses laboratories located at CERN) the next step is to release the contracts for low-voltage components, which should be accomplished in the first half of 2013.