Korea awards contract for ITER thermal shields

12 Mar 2013

-

Ji-min Song, ITER Korea

The ITER thermal shield will be installed between the magnets and the vacuum vessel/cryostat in order to shield the magnets from radiation.

The Korean Domestic Agency signed a contract with SFA Engineering Corp. for ITER thermal shields on 28 February. The contract covers the detailed design of manifolds/instrumentation, the manufacturing design and the fabrication of the thermal shield system. "For us, this is a big step forward for the Korean contribution to ITER," said Myeun Kwon, president of the National Fusion Research Institute, after the signing.

SFA is a leading company in industrial automation with much experience in the procurement of advanced equipment related to fusion, accelerator, and space technology. SFA was deeply involved in the manufacturing and assembly of the Korean tokamak KSTAR.

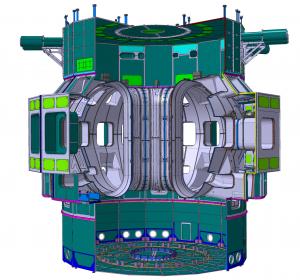

The ITER thermal shield will be installed between the magnets and the vacuum vessel/cryostat in order to shield the magnets from radiation. The thermal shield consists of stainless steel panels with a low emissivity surface (<0.05) that are actively cooled by helium gas, which flows inside the cooling tube welded on the panel surface. The temperature of helium gas is between 80 K and 100 K during plasma operation. The total surface area of the thermal shield is approximately 4000 m² and its assembled body (25 m tall) weighs about 900 tonnes.

Young Hwan Kang, Won-Sub Kim, Frank Jeon, SFA CEO Young Min Kim, NFRI President Myeun Kwon, KO-DA DDG Hyeon Gon Lee, Hee-Jae Ahn, Chang Young Oh, and Wooho Chung were present during the signature.

The key challenges for thermal shield manufacturing are tight tolerances, precision welding, and the silver coating of the large structure. The thermal shield also has many interfaces with other tokamak components. "The Korean Domestic Agency is satisfied with this contract because the thermal shield is one of the most critical procurement items in the ITER Project. We will do our best in collaboration with the ITER Organization to successfully procure the ITER thermal shield," said Hyeon Gon Lee, DDG of the Korean Domestic Agency, on the occasion of the contract signature.