Europe manufactures its first cryopump components

The European Domestic Agency for ITER, Fusion for Energy, started the new year with the completion of an important milestone linked to Europe's contribution to ITER: the successful manufacturing of the cryopanels and thermal shields for the pre-production cryopump (PPC).

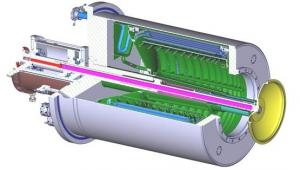

The pre-production cryopump will be the spare for ITER's eight cryopumps (two in the cryostat and six in the torus). The cryopumps will be constantly operational and will play a vital role in the production of the ultra-high vacuum inside the vacuum vessel. In a nutshell, these components will help attain optimum plasma performance.

After an intense period of research, development and design, Fusion for Energy was entrusted with the responsibility of manufacturing the components. In November 2012, a series of contracts were signed with four companies based in Germany and in France, as well as with the Karlsruhe Institute of Technology (KIT) for the manufacturing of the pre-production cryopump.

The pre-production cryopump and the rest of the torus cryopumps will operate with helium at 3.5 K (-269.5ºC). They consist of the cryopanels, which perform the pumping action, and thermal shields that protect the cryopanels from excessive thermal loads. The components were put through complex dimensional controls and ultra-high vacuum leak tests.

The cryopanels have already been delivered to KIT and the thermal shields to Research Instruments, a German company that will integrate the manufacturing activities. At KIT, the cryopanels will be sprayed with charcoal, which is necessary for the pumping of helium and hydrogen isotopes from the torus. Research Instruments, together with Alsyom/Seiv will play a pivotal role in the production of the rest of the cryopump components, assembly, as well as the final cold ultra-high vacuum leak tests for the pre-production cryopump.