European consortium to deliver 100-million-euro robotic system

The European Domestic Agency has awarded a seven-year, EUR 100 million contract to a European consortium for the development, testing and installation of the cask and plug remote handling system—the robotic system at ITER that will ensure the remote transfer of in-vessel components between the vacuum vessel and the Hot Cell Facility for maintenance or disposal.

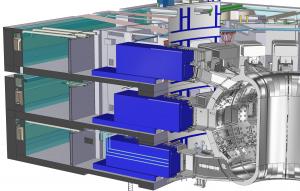

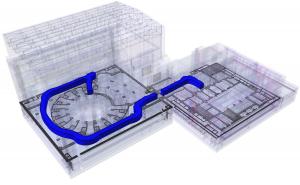

The transfer of components will be carried out with the help of truck-size, double-door containers known as casks. Fifteen of these casks will be on hand to move between the different levels of the Tokamak Building, docking at vacuum vessel ports to collect components in need of repair or replacement, and transporting them in a sealed container back to the Hot Cell Facility. The system is challenging to design due to the limited space in the environment of the tokamak, complex trajectories over multiple levels, and a nuclear environment. The heaviest cask, when charged, will weigh 100 tonnes.

The consortium members bring a wide range of experience in the design and realization of automated systems, the supply of nuclear equipment, mechanical engineering, project management, remote handing and robotics, air cushion technology, and engineering design. The consortium is formed by Airbus Safran Launchers (France-Germany), Nuvia Limited (UK) and Cegelec CEM (VINCI Energy, France), with the support of the UK Atomic Energy Authority (UKAEA), the Instituto Superio Técnico (IST, Portugal), AVT Europe NV (Belgium) and Millennium (France).

As part of its in-kind procurement commitments to the ITER Project, Europe is responsible for four remote handling systems: the divertor remote handling system; the cask and plug remote handling system; the in-vessel viewing system; and the neutral beam remote handling system. The contract for the cask and plug remote handling system announced on 27 October is the last—and the largest in value—to be signed over to industry for realization.

Read the full report and press release published on the European Domestic Agency website.