Contracts for coils, in-vessel viewing system and networks

3 Apr 2016

-

European Domestic Agency, Fusion for Energy

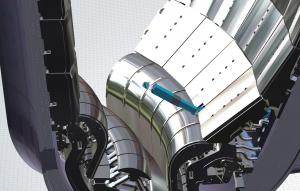

A section of the ITER vacuum vessel with one probe forming part of the in-vessel viewing inspection system that will aid operators to carry out visual inspection inside the ITER machine. The contract for the realization of the system was awarded to CNIM and its subsidiary Bertin Technologies. ©Fusion for Energy

The European Domestic Agency has announced recent contract awards totalling EUR 140 million for high-tech engineering, R&D tasks and civil construction works for ITER. The beneficiaries of these contracts are two firms from France—Constructions Industrielles de la Méditerranée (CNIM) and the Spie Batignolles Group in association with ADF.

The Toulon-based group CNIM, which is already manufacturing half of the toroidal field coil radial plates on behalf of Europe, has been awarded a contract for poloidal field coil manufacturing. Included in the scope of the four-year contract is the fabrication and testing of a mock-up coil to validate processes, the subsequent manufacturing of four poloidal field coils ranging in weight between 200 and 400 tonnes, acceptance controls, and cold testing at approximately -193 ˚C/ 80 K. This is the fifth contract signed by Europe to cover the activities related to the fabrication of poloidal field coils 2,3,4 and 5, which will be produced in a dedicated facility on the ITER site.

A second contract has gone to CNIM and its subsidiary Bertin Technologies for the realization of ITER's in-vessel viewing system, a high-tech robotic viewing system that will aid ITER operators to carry out visual inspection inside the ITER machine. The seven-year contract covers the design and installation of six remotely controlled visual inspection and measurement systems capable of operating in the harsh environment of the vacuum chamber and of taking 3D pictures with a resolution of 1 to 3 millimetres.

The Spie Batignolles consortium (Spie Batignolles TPCI/Spie Batignolles Sud-Est/Valérian) and ADF have been awarded a contract to deliver on-site electricity and hydraulic networks. Civil engineering works carried out under this contract include services trenches, a precipitation drainage system to collect runoff water, hydraulics networks, outdoor lighting, roads, and parking areas over a total surface area of 200,000 m2. Spie Batignolles was the contractor that built the Poloidal Field Coils Winding Facility and the Cryostat Workshop.