Cryostat lower cylinder now on stage

The Cryostat Workshop, in the northeast corner of the ITER worksite, has become a crowded and busy place. There are now two 30-metre assembly platforms supporting assembly and welding work on the cryostat base and the cryostat lower cylinder.

At the other, workers are positioning the first elements of cryostat lower cylinder on a specially constructed assembly platform that will support the five-metre-tall elements as they are aligned and welded.

The space between the two work areas is almost fully occupied by large steel elements, as yet unwrapped and waiting to be assembled.

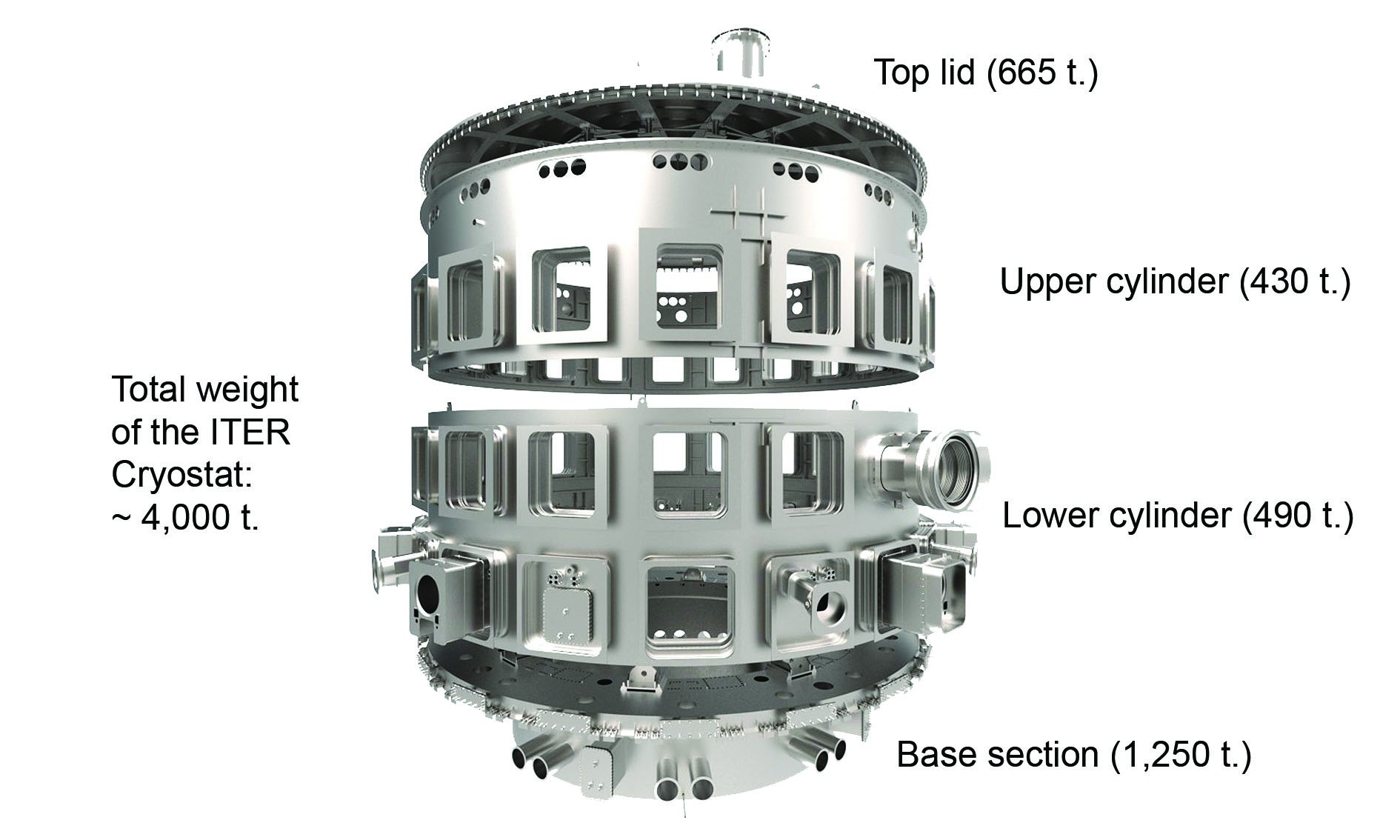

Whereas the massive presence of the base section conveys the exceptional size of the ITER cryostat (30 metres high and 30 metres in diameter once completed), the early stages of lower cylinder assembly reveal its complexity.

The three segments of the lower cylinder that are already positioned on the assembly frame help us to visualize what the completed cryostat will look like: a huge cylindrical steel vessel pierced with dozens of openings. Some are perfectly circular, some are the size of an average window with rounded angles, and a few are as high and wide as a cathedral door.

And we're only seeing half of the lower cylinder. Six tier-two segments, also five metres tall, are expected to arrive at ITER in late July from their manufacturing location in India. Once completely assembled, the full lower cylinder section will measure 10.4 metres in height and weigh 375 tonnes.

In the weeks and months to come, work will progress in parallel on the two lower sections of the cryostat.

The bottom plates of the cryostat base (tier one) should be fully welded by the end of this month. At that point, the six curved rim elements of tier two will be installed to be welded to tier one.

On the other side of the shop, the three remaining tier-one segments of the lower cylinder will join the three already on the assembly platform to form a full ring.

Before our eyes in the Cryostat Workshop, one of the most spectacular and strategic components of the ITER machine is taking shape. Once completed, it will be the second largest and by far the most complex vacuum-tight container ever built.