Central solenoid

A symbolic first

9 Oct 2017

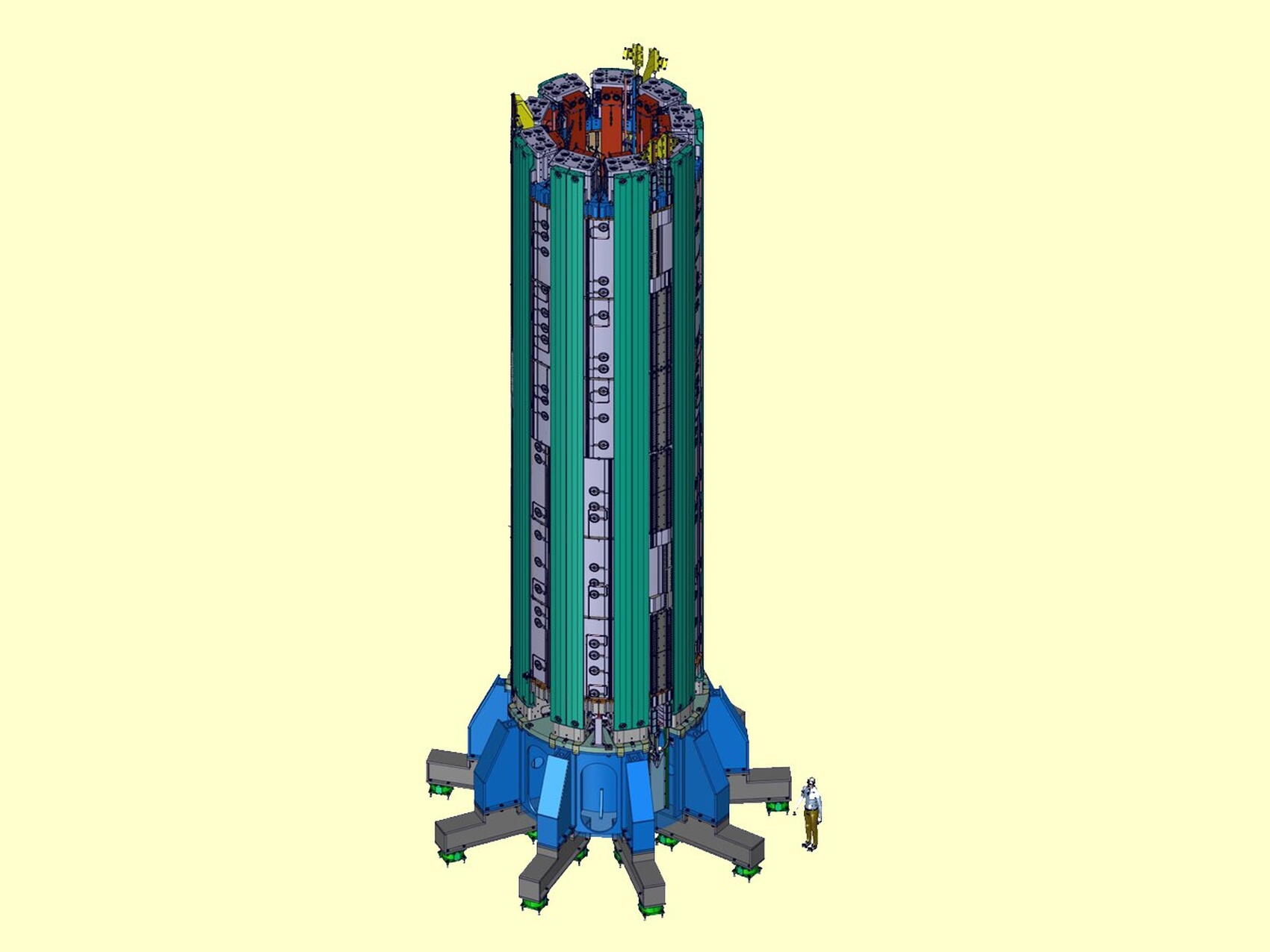

It was just a heavy oversized crate. But its contents had an important symbolic value for the ITER Project. The load that was delivered on Thursday 5 October contained the first shipment directly connected to one of the most spectacular of all ITER components—the 1,000-tonne central solenoid, a pillar-like magnet standing 18 metres tall at the very core of the machine.

The central solenoid assembly platform was delivered on Thursday evening and put into storage the following morning. Personnel from the ITER Organization, the US Domestic Agency and ITER global logistics provider DAHER attended the delicate operation.

Part of US commitments to ITER, the central solenoid comprises six cylindrical modules plus structure subsets that will be assembled on site by the ITER Organization. Set to begin in 2019, delivery of all modules should be complete by 2021.

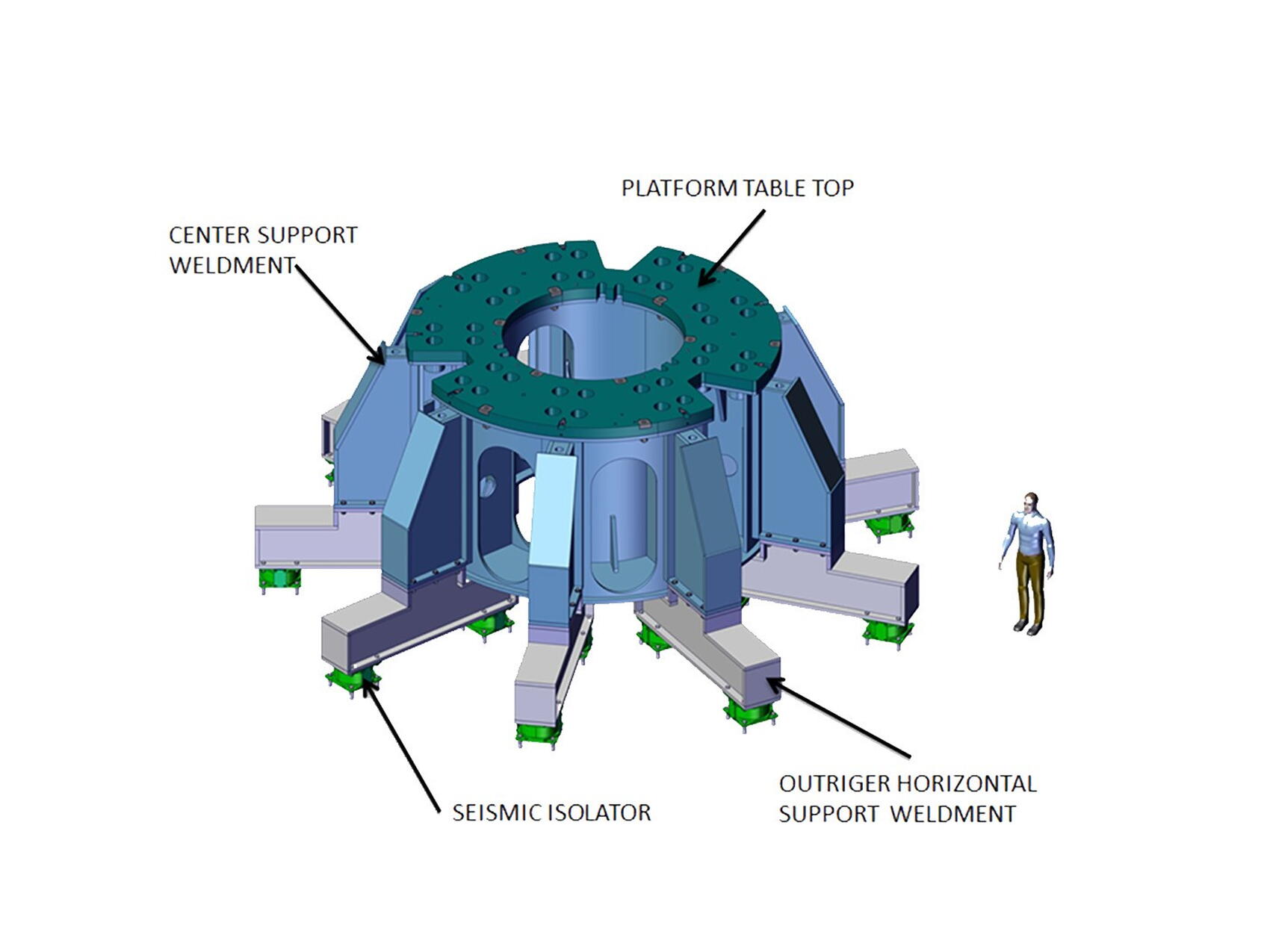

The crate contains the main steel components of the central solenoid assembly platform—a thick steel structure that will be used throughout the assembly phase from early 2021 to mid-2023. The steel segments were manufactured by Robatel in Genas, near Lyon, France, under the terms of a contract from the US Domestic Agency.

In addition to the centre support weldments and the platform table just delivered to ITER, the central solenoid team is also expecting nine thick, beam-like legs (the "outriggers") to be delivered at a later date.

Each outrigger will rest on a pair of seismic isolators anchored into the floor of the Assembly Hall, where all assembly operations will be performed (see drawing in the photo gallery).