Review of ITER's upper port plugs

25 Jun 2010

-

Spencer Pitcher, ITER Diagnostic Physicist

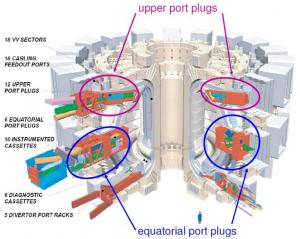

One key aspect of the research program of ITER is the diagnosis of the plasma and the first wall, e.g., the plasma temperature, its density, its radiative properties, its first-wall resilience. For this purpose, a large number of diagnostics peer into the ITER vacuum vessel from many different vantage points.

The focus of the design review being held next week here in Cadarache is the generic location known as the upper port plugs. The diagnostic generic upper port plug (GUPP) design is meant to be common to all upper port-based diagnostic systems. It provides a common platform, or support/container, for a variety of diagnostics. In addition, the port plug structure must contribute to the nuclear shielding, or plugging, of the port and further contain circulated water to allow cooling during operation and heating during bakeout. The port plug must withstand disruption forces, thermal stresses and seismic events.

The design of the GUPP represents the culmination of two years of collaborative work involving the ITER Organization, most of the Domestic Agencies—including a leading role by the US-DA (Princeton Plasma Physics Lab)—and several industrial contractors.