China successfully tests correction coil current leads

23 Jul 2010

-

Pierre Bauer, ITER Superconductor Section

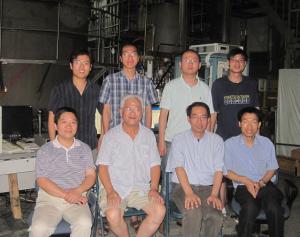

The ASIPP high temperature superconductor current leads team: (back left to right) H. Feng, L. Niu, X. Huang, T. Zhou; (front left to right) Y. Song, Y. Bi, Y. Yang, K. Ding

The high-temperature superconductor current leads are designed to transmit high currents from the room-temperature power supplies to the low-temperature superconducting coils with minimum heat load.

For this they use a short segment with high temperature superconductor (HTS), which can carry much higher current-densities than normal conductors such as copper. It can therefore conduct the current using much less material (smaller cross-sections), thus reducing the heat conduction.

The heat load reduction by the HTS current lead results in a decrease of the power input (here cryo-power), greatly improving the efficiency of the ITER device. The HTS current lead technology is therefore one of the "enabling" technologies for a fusion tokamak.

The HTS current leads are part of the so-called feeders, a set of ITER components provided by China.

The Institute of Plasma Physics of the Chinese Academy of Sciences (ASIPP) in Hefei, China, started development of such current leads more three years ago. In Dec 2008, Newsline reported on a successful test of a 68 kA current lead prototype needed for a toroidal field coil feeder.

For this they use a short segment with high temperature superconductor (HTS), which can carry much higher current-densities than normal conductors such as copper. It can therefore conduct the current using much less material (smaller cross-sections), thus reducing the heat conduction.

The heat load reduction by the HTS current lead results in a decrease of the power input (here cryo-power), greatly improving the efficiency of the ITER device. The HTS current lead technology is therefore one of the "enabling" technologies for a fusion tokamak.

The HTS current leads are part of the so-called feeders, a set of ITER components provided by China.

The Institute of Plasma Physics of the Chinese Academy of Sciences (ASIPP) in Hefei, China, started development of such current leads more three years ago. In Dec 2008, Newsline reported on a successful test of a 68 kA current lead prototype needed for a toroidal field coil feeder.

ASIPP tested two prototypes of the 10 kA high temperature superconductor current lead for the ITER correction coil feeders.

Now the ASIPP HTS team has successfully tested two prototypes of the 10 kA HTS current lead for the ITER correction coil feeders. On 4 July 2010, the HTS current lead was operated for several hours at the peak 10 kA current, which is 20 percent above the average current during a typical correction coil powering cycle.

The results were discussed at a special meeting of the ITER HTS working group at KIT in Karlsruhe, Germany, last week (15-16 July). This successful test completes the HTS current lead R&D conducted at ASIPP in preparation of the feeder final design review this coming September for which the feeder teams in China and at the ITER Organization are now feverishly preparing.

The results were discussed at a special meeting of the ITER HTS working group at KIT in Karlsruhe, Germany, last week (15-16 July). This successful test completes the HTS current lead R&D conducted at ASIPP in preparation of the feeder final design review this coming September for which the feeder teams in China and at the ITER Organization are now feverishly preparing.