First coil leaves production line

As long as a semi-trailer, nearly as heavy as a fully loaded Boeing 747, the first ITER ring magnet to be manufactured by Europe on site—poloidal field coil #5 (PF5)—has exited the building to await its turn for assembly in the Tokamak pit.

It was grey and cold, but for the 20 people assembled it was a day that would not be easy to forget. The sight of the ring-shaped superconducting magnet emerging from the production facility where it had been more than three and a half years in the making was both historic and moving.

For Alessandro Bonito-Oliva, the Magnets Programme Manager for the European Domestic Agency Fusion for Energy, this first coil produced entirely on site by European contractors served as an important learning curve for the three other coils to come (PF2, PF4 and PF3). "We learned a lot, improved and developed techniques to overcome [...] technical difficulties along the way. Fusion for Energy supervised the entire production from the start, and with the valuable contribution of our contractors we delivered [the first poloidal field coil] made in Europe."

From the start of coil winding activities in September 2017, to resin impregnation, final assembly, and cold testing, the realization of PF5 was a meticulous, stage-by-stage process that required the expertise of a dozen companies and more than 150 people.

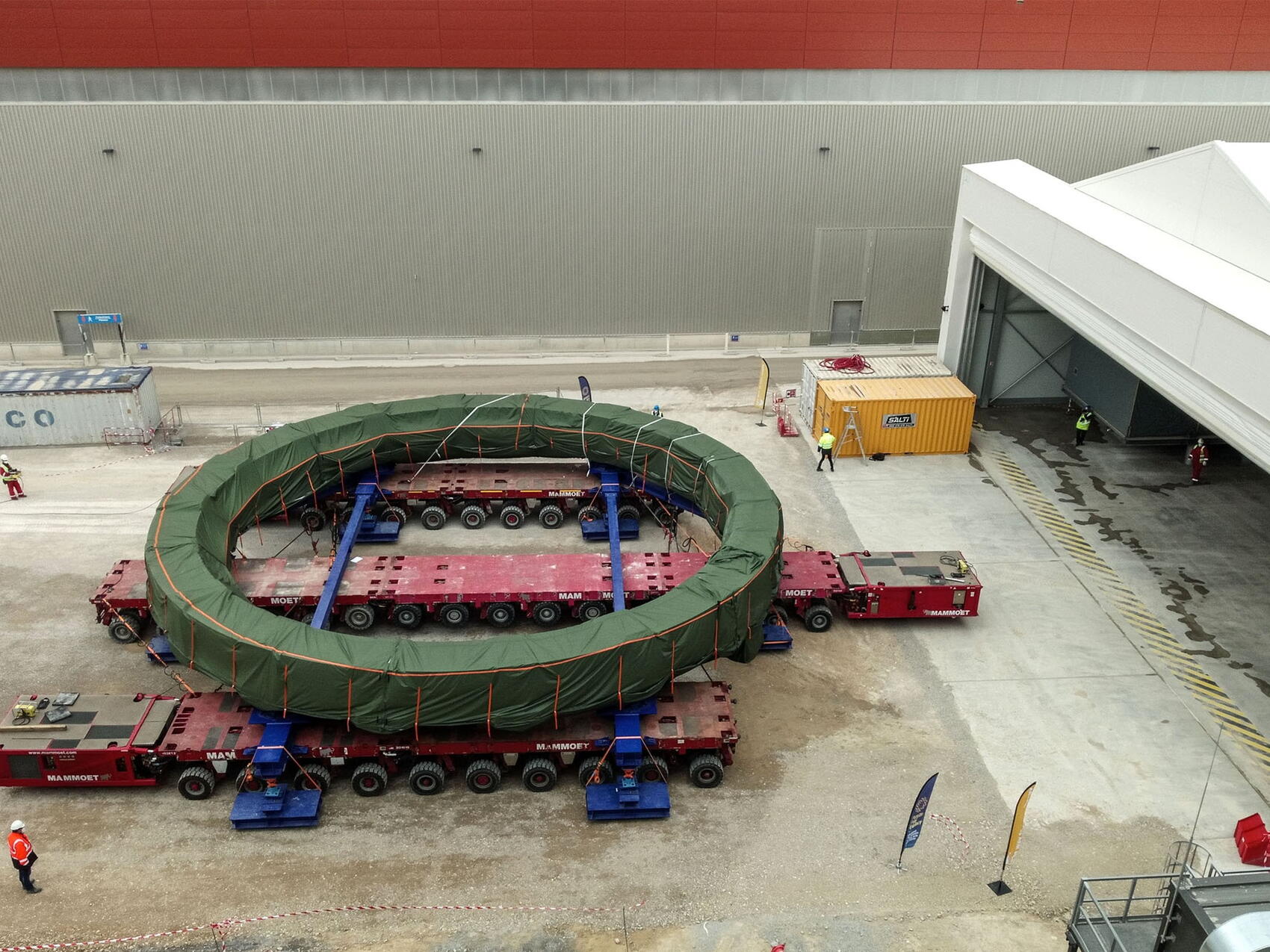

A few days before the scheduled operation, three self-propelled modular transporters, piloted in sync, had entered the north end of the winding facility. Powered by 1000 HP hydraulic power packs and with the maneuverability of 36 axels and 144 wheels, the transporters passed under the coil frame and lifted the 340-tonne component (plus frame) off the ground. On Friday 16 April, the coil, protected under heavy-duty tarpaulin, was brought out of the coil building and delivered around the corner to a temporary storage tent.

Now officially handed over to the ITER Organization, ring coil PF5 will wait its turn in the machine assembly sequence.

See a full report on the Fusion for Energy website.