All shine and precision

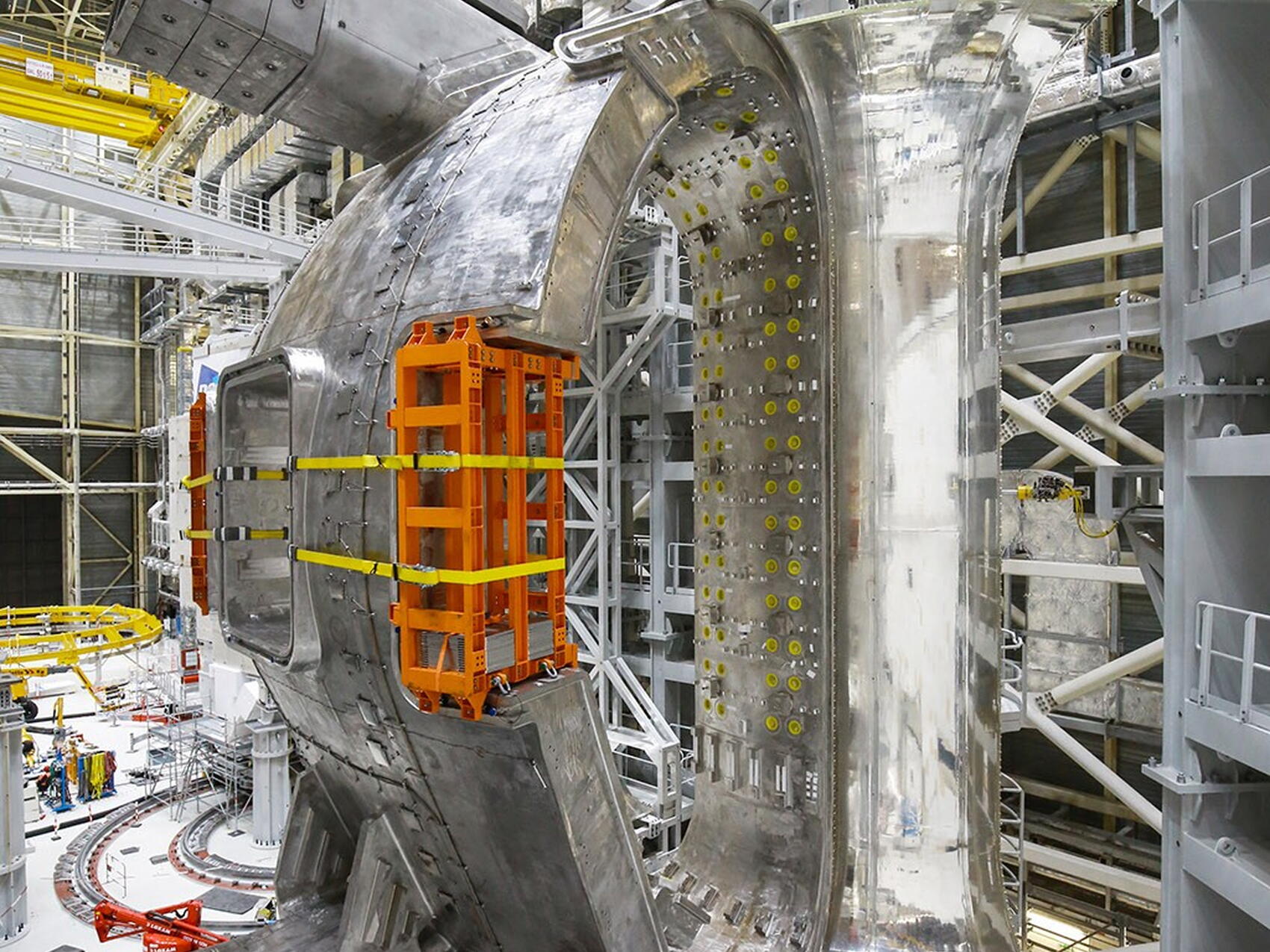

Then came the inboard panel of thermal shielding designed and built for sector #6. The inboard panel was attached to the right wing of the tool in February 2021, and rotated in towards the vertical sector in April. It has since been attached firmly with 16 clamps, married so closely to the shape of the sector that only its polished silver surface distinguishes it from the duller grey of the steel sector.

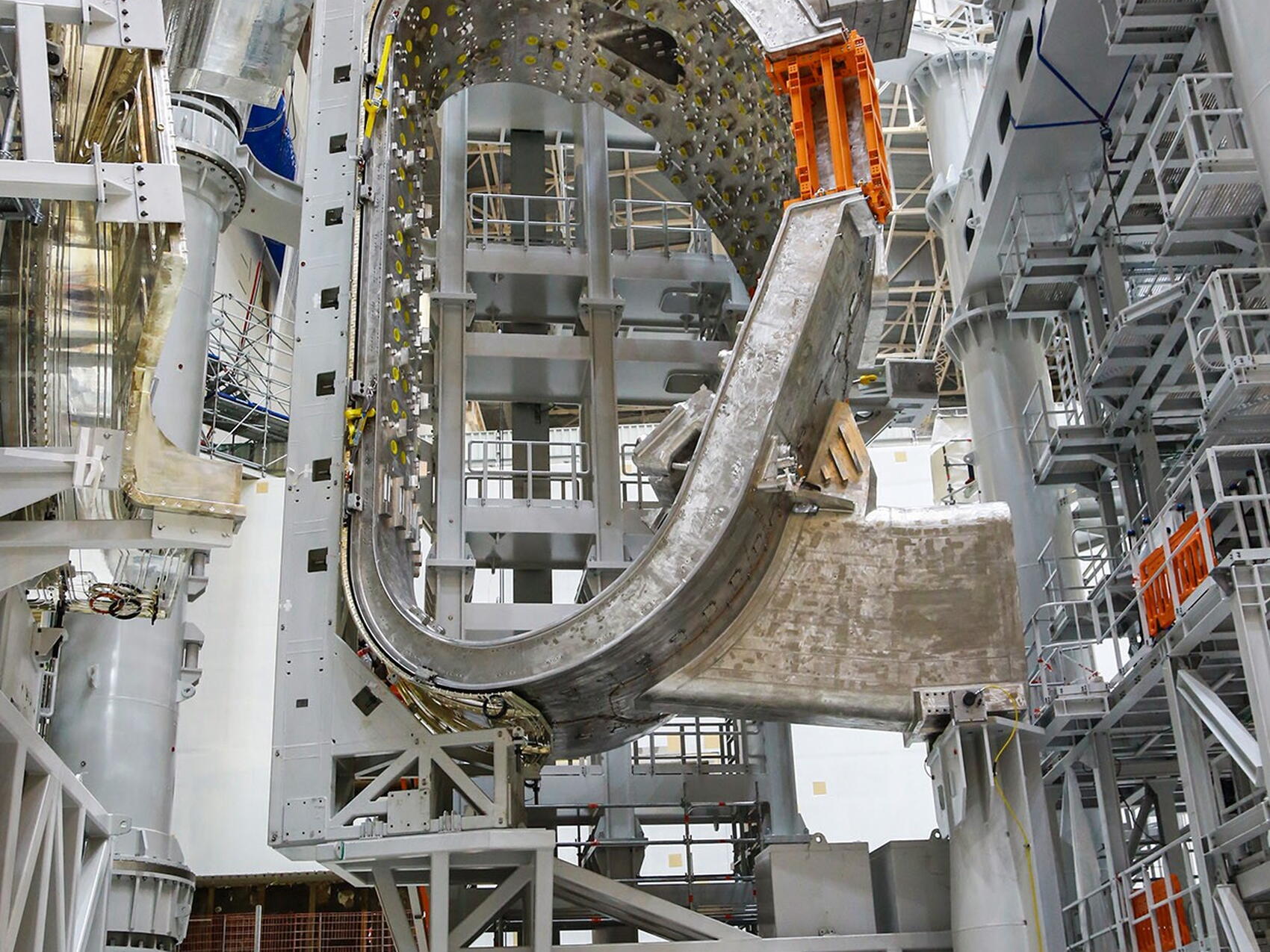

And now, two outboard thermal shield sections have been posiitoned on the wings of SSAT-2 for rotation and alignment. The operation was rehearsed earlier this year; when finished in July, vacuum vessel sector #6 will be fully cloaked in a thermal barrier that will prevent the transfer of heat from the vessel to the ultra-cold superconducting magnets.

To complete the first sector sub-assembly, two toroidal field coils must be positioned and attached. While the assembly teams work to complete the inboard and outboard assembly of the thermal shield, toroidal field coil #12 (TF12) has been positioned temporarily on the adjacent sector sub-assembly tool.

Special thanks to Chang Hyun Noh, Thermal Shield Manufacturing Engineer, for the photo coverage.