Co-locating port plug assembly and testing

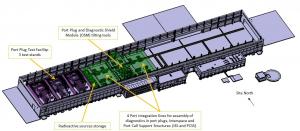

For about 20 of the ITER ports that house diagnostics elements, the path to installation in the tokamak passes through a Port Integration Facility on site. Side by side, the port plugs will be equipped with their tenant systems and tested at operating temperature prior to transfer to the assembly arena.

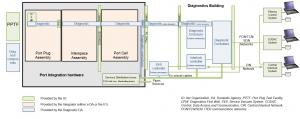

Port integration is a responsibility shared by all seven Domestic Agencies as well as the ITER Organization, which is procuring a certain number of diagnostics directly. While Domestic Agencies will handle integration of their port plugs domestically, port plugs procured directly by the ITER Organization, and all support structures (except those procured by the European Domestic Agency), will be assembled in the on-site Port Integration Facility.

Port assembly activities include the assembly not only of the diagnostic equipment that sits inside a port plug, but also of the equipment behind the plug, which includes the interspace support structure and the port cell support structure (see diagram below). The diagnostics include sensors, and also the reflectors and mirrors that collect signals. In some cases, sensors are placed behind the plug for extra protection from radiation.

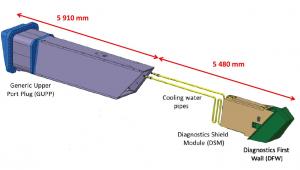

The upper port plugs present their own set of challenges, requiring a different set of tools and cranes. While each upper port plug will contain only one diagnostic shield module, both the port plug structures and the modules are longer (6 metres and 5.5 metres, respectively compared to only 3 and 2.6 for the equatorial plugs). A total of 14 metres are needed in a vertical direction to insert a diagnostic shield module into an upper port plug.

Once assembled, the port plugs have only a short distance to travel to be tested. Three separate test stands—called port plug test facilities—are planned, with a fourth delivered directly to the European Domestic Agency for the testing of port plugs under its responsibility. Environmental (leak tightness, vacuum and thermo-hydraulic performances) and functional tests (radio frequency acceptance tests, behavior of the plugs' steering mechanism and calibration of diagnostics) will be performed on all upper and equatorial port plugs, driven by the high machine availability requirement for the diagnostics port plugs.

"The advantage of having the assembly tools next to the test facility is that if a port plug fails the test, we will have the tools to un-mount it and to disassemble and reassemble it," says port plug test facility engineer Thierry Cerisier. "In the worst case, we will only need to ship back a part of the port plug."

The Port Integration Facility will be installed in the current Poloidal Field Coils Winding Facility on site, taking over space that is progressively vacated as winding activities come to an end. The space meets Port Integration Facility requirements for physical dimensions and access—and very importantly, for cleanliness and cranes. The first installation activities are planned for January 2024.

***The ITER Organization is organizing a virtual information meeting on the general procurement strategy for the package "Engineering Design of the Port Integration Facility and Tooling" on Tuesday 5 October. All interested industrial actors from the ITER Members are invited to register for the event here. (Please note: Registration closes at the end of business on Tuesday 28 September.)