Sector repair has started

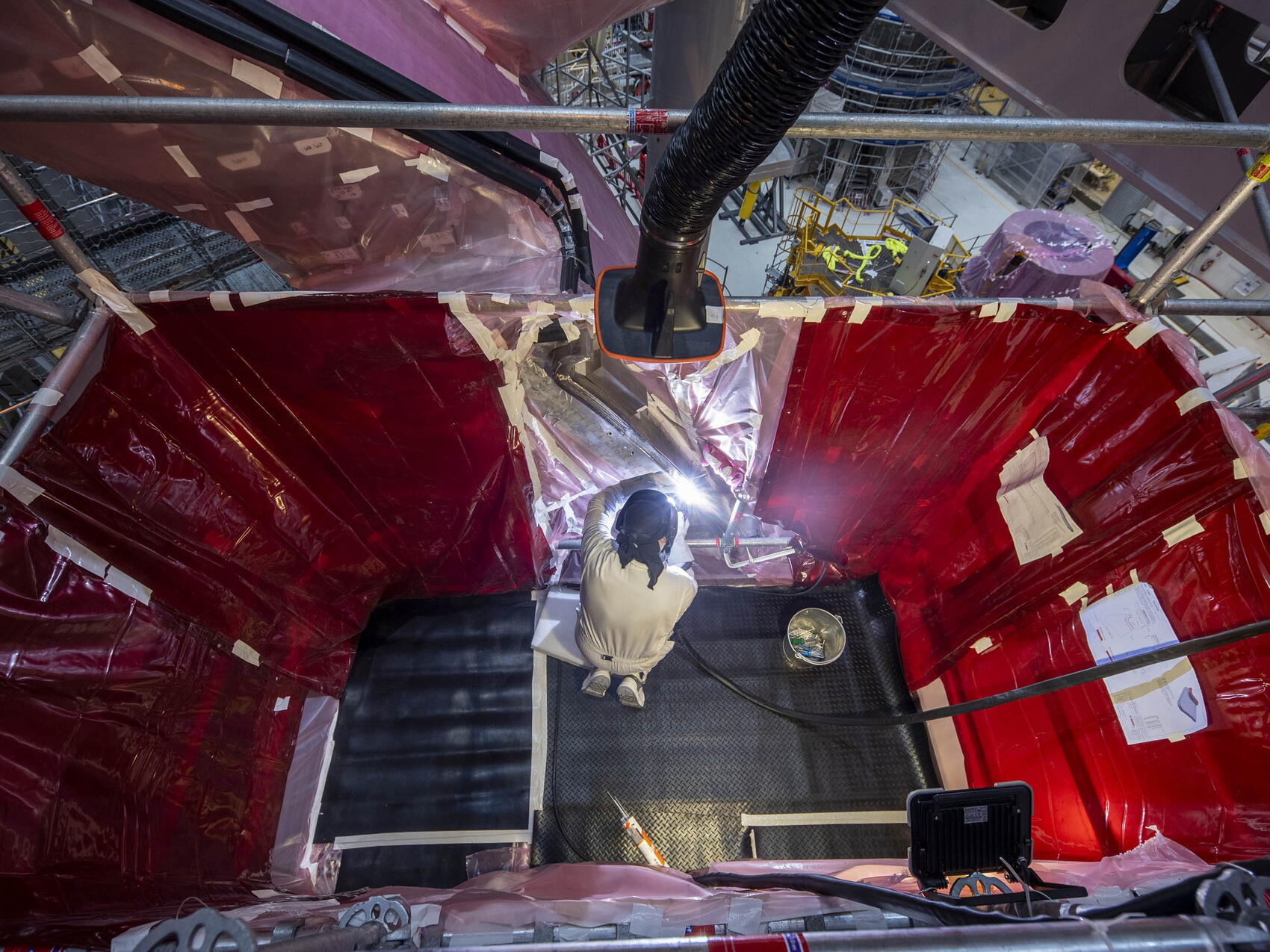

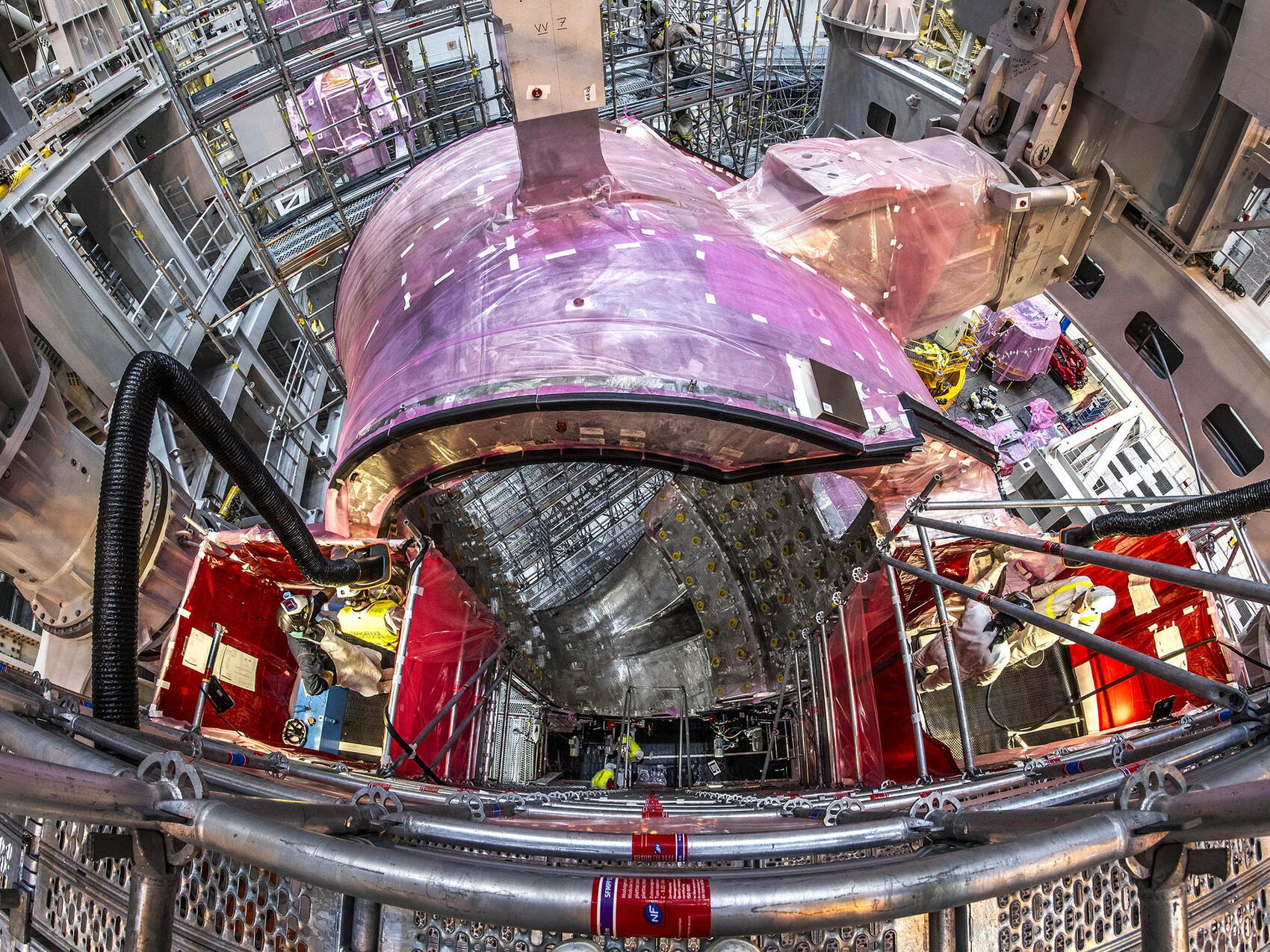

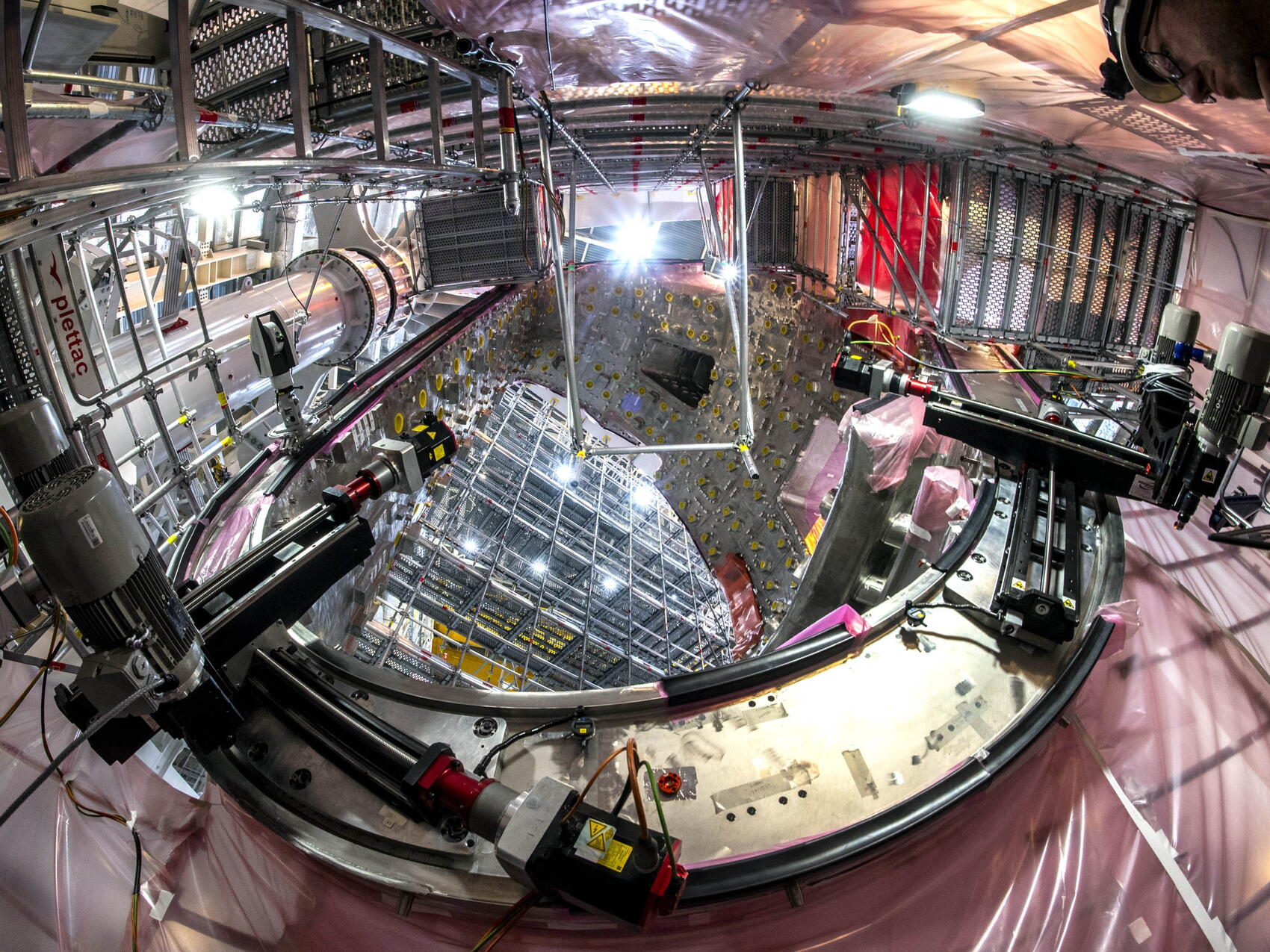

Built up against vacuum vessel sector #7, the scaffolding reaches almost 20 metres in height and masks the massive component. Streaks of blinding light, filtered by thick, semi-transparent red plastic sheets, flash here and there—proof that in the ITER Assembly Hall, the repair campaign has begun in earnest.

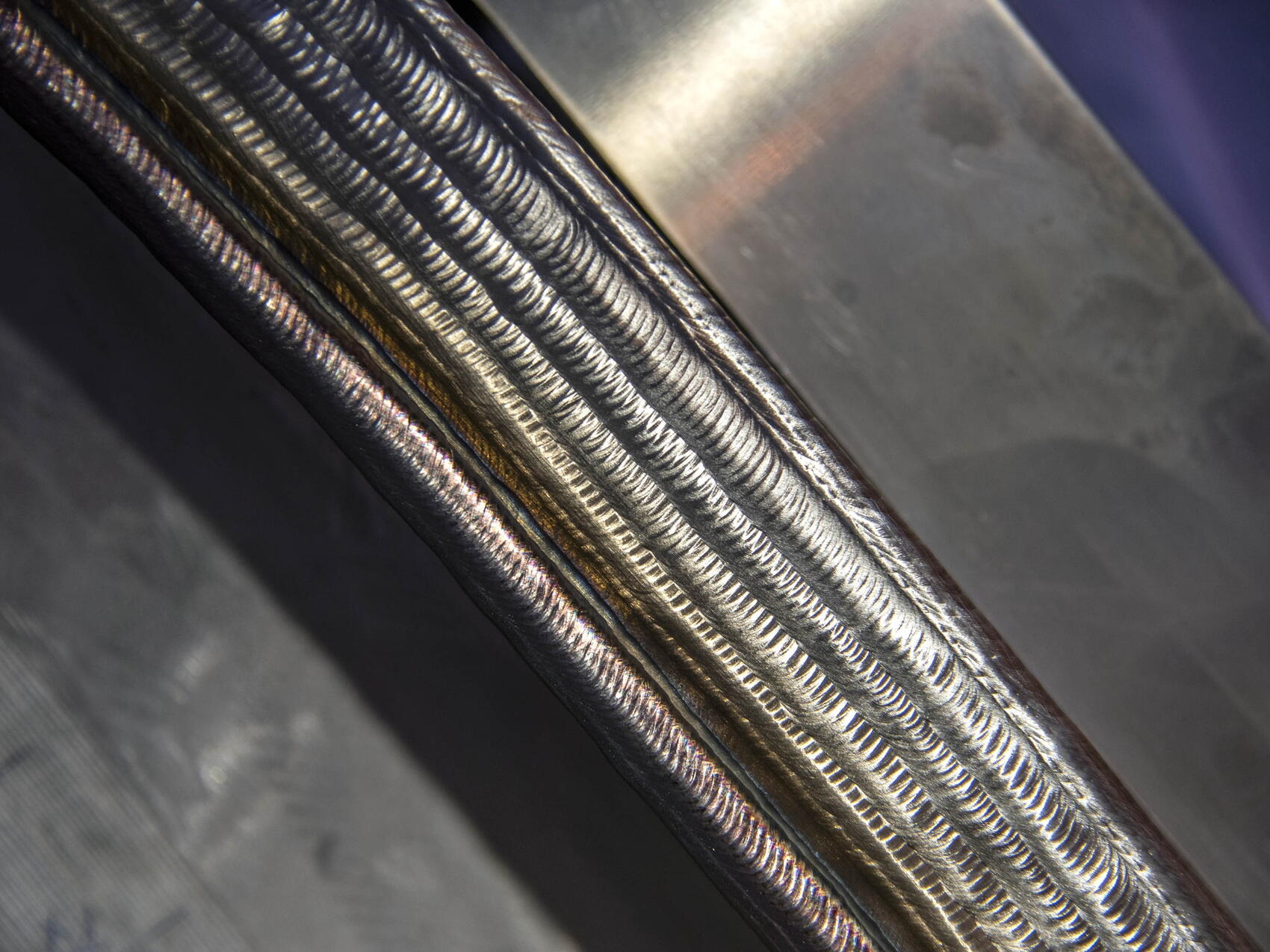

On small platforms that extend out from the main structure, four welders are concentrating on their highly meticulous job. Pass after pass, following a strictly predefined pattern, they deposit small beads of melted metal on the faulty sections of the sector joint region, called the bevel. As welding rods are consumed one after the other, the deposits grow and reach the required thickness. In a second stage automated machining tools, some of them already positioned, will remove the excess build-up and restore the bevel's geometry as close as possible to nominal.

For an experienced welder the operation is simple, almost routine. However, it requires extreme concentration to achieve uniformity, homogeneity and reliability. It is also a lengthy operation—it is estimated that sector #7, like sector #6, will require approximately 24 kgs of metal fill-up before machining.

The repair operations that have begun on vacuum vessel sector #7 are the result of close to one year of preparation and strategy refinement. Metal build-up and machining were practiced on "representative coupons"—1.4-metre-long mockups of vacuum vessel bevel sections—and mechanical properties were tested before validating the procedures that are being implemented.

"From the beginning, we have worked and continue to work as an integrated project team," says Alessandro Bonito-Oliva, the head of ITER Tokamak Program. "We are also proceeding in close connection with our European Domestic Agency counterparts who are implementing similar operations on the yet-undelivered vacuum vessel sectors."

See the photo gallery below for more detail about the start of vacuum vessel sector #7 repair.