Extreme vigilance, successful installation

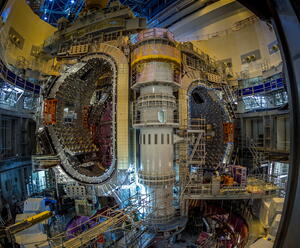

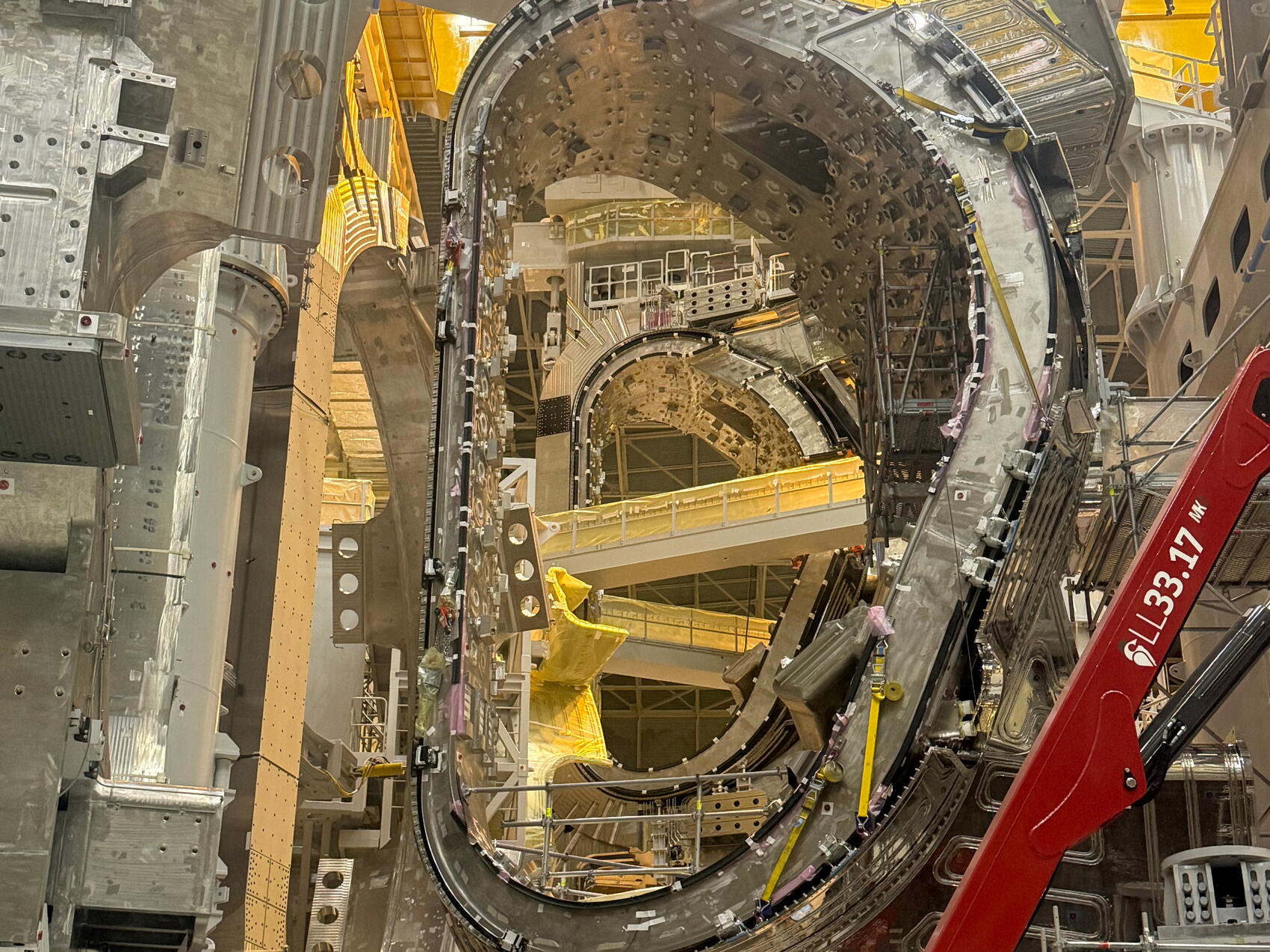

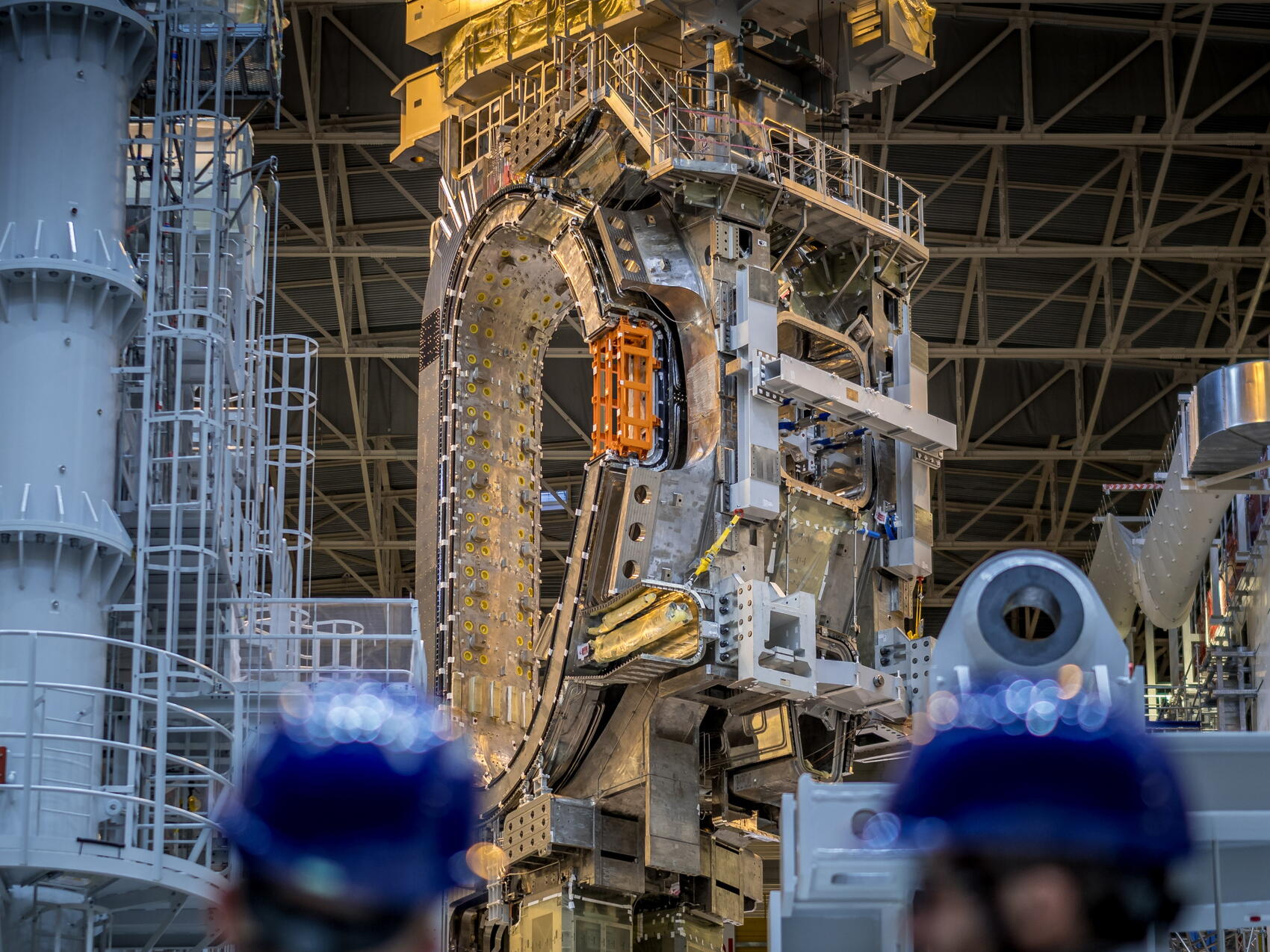

The fourth of nine sector modules has been successfully lowered into place using an approach that treats each installation as a first-of-its-kind operation to ensure readiness for any eventuality. The two-day operation tested, once again, the accuracy of the metrology system and the navigation skills of the assembly team.

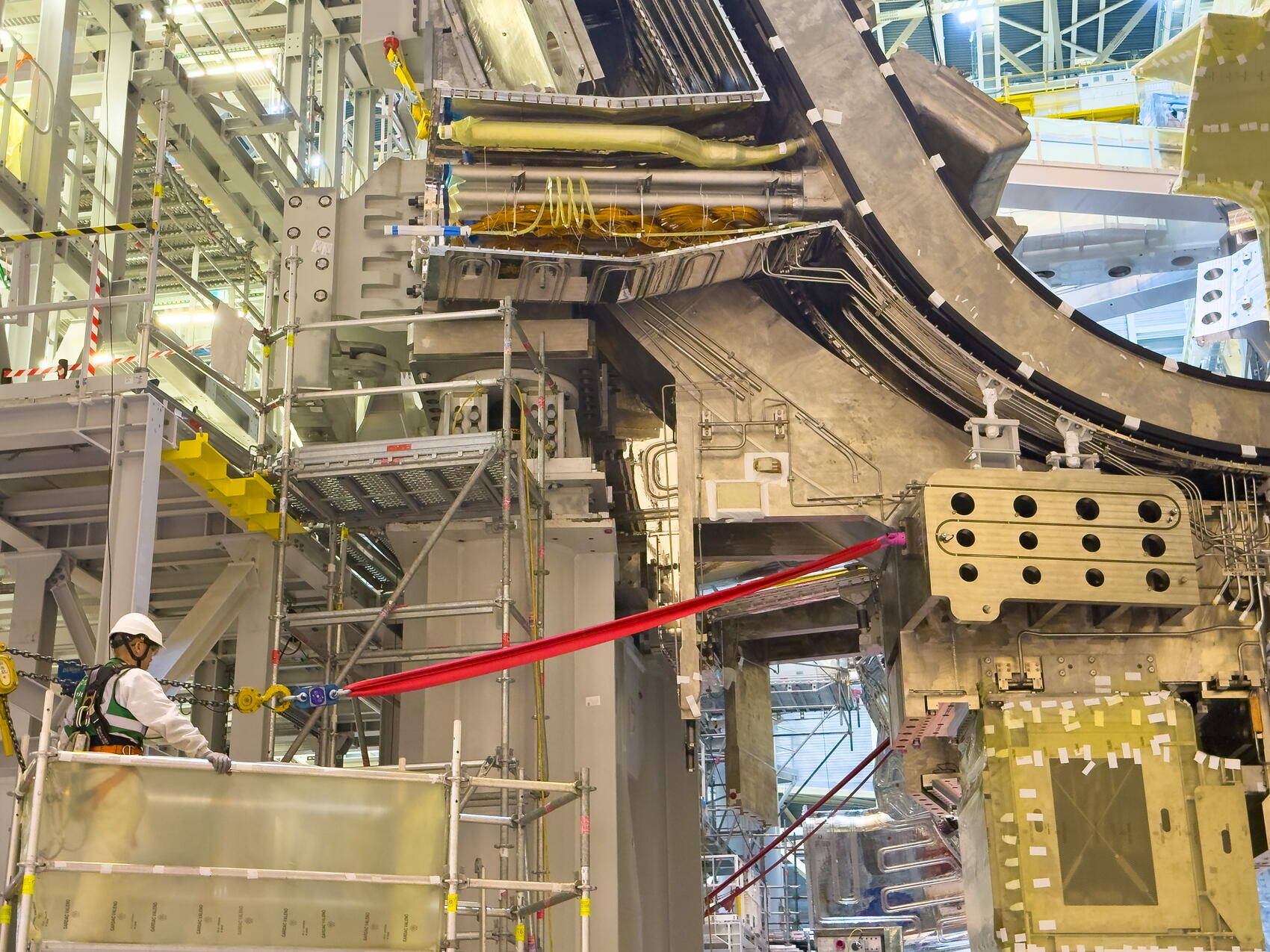

No two major lifts are alike. For sector module #8, the largest challenge was the small gap that existed between the top of the load and the support beam above it—a gap that would narrow with the pressures of the lift from just a few millimetres to as little as 0.4 mm.

“This was an excellent chance to confirm the reliability of our sensors and our ability to adapt to small margins of manoeuvrability,” said Mathieu Demeyere, the principal construction manager who supervised the operation for ITER. “As we move forward with assembly, we will need to move components through the tightest of spaces and now we know we can adjust to extremely narrow margins.”

The operation to insert the 1,300-tonne sector module #8 into the tokamak pit began with pre-job briefings on the morning of 28 January and ended with the landing of the component on the evening of 29 January. From the very beginning, supervisors warned of overconfidence and urged their teams not to fall into a routine after the efficient placement of three modules last year. This proved vital as sensors began reporting the gap between the component and the support beam was shrinking and the teams had to take extra precautions to ensure there was no contact.

“Vacuum vessel assembly is moving quickly and we have a record of success—this is a situation where you need to be especially vigilant,” said Gael Hardy, the lift engineer from Framatome who has helped manage all the sector module installation operations to date. “By guarding against overconfidence, you are able to detect weak signals and adapt to any differences that emerge, just as we did with sector module #8.”

The same vigilance is applied to safety during the operation. The two-day task of sector module installation is carried out by two separate teams that work on alternating 12-hour shifts. Each shift is overseen by a health, security, and environment (HSE) expert to minimize risks to team members.

“We treated sector module #8 as the fourth first-of-its-kind operation,” said Clément Vautrin, the HSE engineer who oversaw two of the 12-hour shifts. “We have achieved a clean safety record so far by considering that each installation is unique.”

Over the coming weeks, a few final adjustments will be made to the sector module. First, a radial shift will push it 140 mm closer to the central column. Then, the intercoil structure connections that link sector module #8 to the adjacent sector module #7 will be completed.

With the installation of sector module #8, the plasma chamber is now almost half complete. Sector module #7, sector module #6, and sector module #5 were inserted in 2025, and the schedule for 2026 is even more ambitious, with a total of four insertion operations scheduled.

The lessons learned during the installation of sector module #8, notably the ability to navigate incredibly tight tolerances, will be especially valuable as space in the tokamak pit decreases and as a sector module will for the first time have to be installed between two sectors later this year—an operation requiring the kind of pinpoint accuracy that was demonstrated last week.