you're currently reading the news digest published from 24 Sep 2018 to 01 Oct 2018

featured5

of-interest1

video1

press6

featured

Fusion electricity | Navigating Europe's course

Since 2013, the European Roadmap to Fusion Energy has been the fundamental document guiding European priorities in fusion R&D until the ultimate goal—achieving electricity from fusion energy. On the occasion of the release of version 2.0, Newsline asked EUROfusion Programme Manager Tony Donné about the updated document, the role of ITER, and the overall outlook for fusion energy. What is the rationale behind the new Roadmap? I always compare the Roadmap with a navigation system. You program your destination and the navigation system finds you the fastest route. Along the way, it takes account of the traffic situation and road conditions and adjusts the route accordingly to get you to your destination as fast as possible. But sometimes there are new roads and highways and you need an update of your navigation system. Now, six years after the introduction of the roadmap in 2012 we see developments which are really good news for fusion. These were taken into account in the update of the Roadmap. The difference between a navigation system and the fusion roadmap is that the latter is dealing with completely uncharted territory. What are the new elements of the Fusion Roadmap? The European Fusion Roadmap outlines the research and development required to provide the basis for an electricity-generating fusion power plant. This new version is an evolution, not a revolution. In the first Roadmap we took DEMO (the DEMOnstration power plant) as the end point. We were—and still are—aiming at having electricity from fusion as fast as possible. But we didn't look at how we would get from DEMO to a commercial fusion power plant. Now, the design for DEMO will already include the requirements for a future fusion power plant to ensure an easy adaption. The other new element is that the eight roadmap missions are much more interwoven. An example is the stellarator program, mission 8, which will give important input for the development of the heat exhaust, mission 2. Solving this challenge will be very helpful for both ITER and DEMO. The roadmap 2.0 also reflects changes in the ITER Baseline which was renewed about two years ago. We needed to adapt for that as ITER is central to the Roadmap. The revised version is therefore fully aligned with the latest ITER Baseline and Research Plan. How is the central role of ITER reflected in the document? ITER is the central device and roughly 60-65 percent of the present EUROfusion budget is dedicated to research supporting ITER. Most of the campaigns at the European fusion devices are aimed at supporting the ITER Project. At JET, for example, we are conducting specific ITER-relevant tests like the upcoming deuterium-tritium campaign, the shattered pellet injection testing, and the helium campaign. All of these research activities are part of the Roadmap and contribute to the ITER Project. But also, EUROfusion work at the various national devices is strongly focused on research questions in support of ITER. Mission 6 is to develop an integrated design for DEMO in Europe. What is EUROfusion's specific role? DEMO will demonstrate first electricity production to the grid by fusion. The responsibility for the European DEMO lies in essence with Fusion for Energy (F4E), the European Domestic Agency. However, with ITER being the top priority for F4E in the next decade, EUROfusion has been asked to develop the design for DEMO. Taking on this task, we realized that we will have to involve industry from the beginning. Based on experience from various large engineering projects, we believe that the involvement of industry in the pre-conceptual and conceptual design phases will be very advantageous. The first Roadmap stopped with DEMO, the demonstration power plant after ITER. The new version goes further ... An important new element is the involvement of our stakeholders. We have created a stakeholder group with representatives from electricity plants, grid operators as well as representatives from the nuclear and nuclear waste industries. Before fusion energy comes on the market we need to identify the most useful way for fusion power plants to deliver energy for conversion to electricity. We develop this input with our stakeholders to define the requirements for DEMO—it's like a retro-planner for fusion energy. The quest for fusion energy is a global endeavour—does the cooperation foreseen in the Roadmap go beyond Europe? The collaboration has to be global as the development of fusion energy is of global importance. And it is a big challenge, so we all need to work together to achieve this goal of producing energy from fusion. Naturally, our work with ITER is international in the sense that we collaborate with all ITER Members. Our cooperation within Europe and beyond is embedded in the Roadmap. There is intense international scientific collaboration in various fields in order to be efficient in driving scientific discovery and avoiding duplication. At the moment, the most extensive collaboration is with Japan on the Broader Approach which includes research activities on key physics questions using the fusion device JT-60SA or the work of IFMIF (the International Fusion Materials Irradiation Facility) on fusion materials. There is a lot of interaction worldwide in many fields involving all ITER Members, but also others such as Brazil, Kazakhstan and Australia. What is your view on the role fusion energy in the future energy mix? The question really is: do we need fusion electricity? To answer that question I use the example of Germany which is currently subsidizing wind and solar energy concepts with about EUR 25 billion per year. That is roughly equivalent to building one ITER per year. Last year Germany managed to cover 37 percent of its energy consumption from renewables, mostly wind and solar. But, at the same time CO2 emissions from electricity production didn't decrease as fossil fuels such as peat are still being used for the base load. Renewable energy sources have their limitations and even with efficient energy storage facilities we still would need large scale back-up energy sources. This is where fusion can play a vital role by replacing fossil fuels as the base load and contribute to reducing CO2 emissions. Fusion does not compete with other renewables; I believe that there is good place for fusion in the energy mix of the future.

Image of the week | 200 million years ago at ITER

Back in the Mesozoic, some 66 to 250 million years ago, the ITER site lay at the bottom of a shallow sea that covered most of what is now Provence. The warm waters swarmed with life: marine reptiles such as ichthyosaurs and plesiosaurs, sea urchins, belemnites and the ubiquitous ammonite, resembling present-day nautiluses. A few weeks ago, as workers excavated a gallery for the Tokamak's cooling water system, a dweller of this ancient world resurfaced. It wasn't noticed immediately, however. 'We only saw the circular shape imprinted on the rock slab once it had been delivered to the deposit area behind the construction platform,' explains Christopher Lebreton, a foreman with the contractor that is performing the excavation works—SVA (Spie-Batignolles, Valérian, ADF). The shape imprinted on the rock was that of the coiled shell of an average-size ammonite—a species which could vary in size from 20 millimetres to 2.55 metres in diameter. According to Caroline Gamache, a geologist with Spie-Batignolles, the limestone strata where the fossil was found can be dated back 120-200 million years—a time when dinosaurs ruled the Earth and our closest parent was a tiny mouse striving to survive in the realm of the 'monstrous lizards.'

Tokamak Building | Smallest crane gets a lift

Towering 50 metres above ground, 'C1' is the shortest of the five tower cranes operating inside the Tokamak Complex. Standing at the very centre of the bioshield—almost exactly materializing the axis of the ITER machine—it is the one we point to when we have visitors on the worksite. Like its taller sisters, C1 was installed in 2014. Its first mission was to deliver rebar, formwork and all the necessary materials for the construction of the bioshield. Then, the (relatively) short crane was meant to pursue its material-delivery role as the concrete slabs and walls of the Tokamak Building were filled one after the other all around the central machine pit. In the latest, optimized version of the building plan, however, some of the activity sequences have been modified. The C1 crane will have to be operational at level 5 of the Tokamak Building before level 4 is completely finalized, which requires extending the C1 crane by approximately 10 metres. 'Cranes are like Lego,' explains Laurent Moustraire, the 'master of cranes' for the European VFR consortium responsible for building the Tokamak Complex and eight other buildings on site. 'Within limits, they can be modified almost at will.' In the context of the new phasing, C1's mast will be extended approximately 10 metres, allowing the boom to operate well above the upper level walls. A crane's specifications are determined by the 'wind effect'—the forces that are exerted by the wind swirling between the different structures of the construction site. Wind effects are calculated through modellization and, just like for fighter jets, mockups of the cranes are tested in wind tunnels before being commissioned (see video). 'Before choosing and installing the worksite cranes in 2014, we worked for a full year with the French Scientific and Technical Centre for Construction (CSTB) to analyze and modellize the wind effects in the different locations where the cranes were to be installed,' adds Antoine Tardy, VFR's chief methods engineer. A similar procedure was followed for the extension of crane C1. As the wind effect will be greatly increased in the new, taller configuration, it was determined that the mast needed to be reinforced at its base and that extra anchorage had to be created. To this end a set of three steel tubes (Ø 40 cm) will be bolted to one of the heavy concrete walls that stands above the bioshield as shown in the diagram at left. For a few days, we won't be able to point to crane C1 to explain where the machine's axis will be located. Operations began late September and it will take five to six days to dismantle the crane, add the extension, and create the anchorage. But C1 will stand again, taller and sturdier like a beacon for the future ITER Tokamak.

On site | A runway for the cryostat

A section of runway-worthy tarmac has been completed at ITER. But no plane will ever land here. On three consecutive evenings last summer, work proceeded into the night to finalize the surfacing on a 5,000 m² area near the Cryostat Workshop. The road works were carried out to prepare for the relocation of a completed section of the ITER cryostat—the 375-tonne lower cylinder—from the workshop to a dedicated storage area on the platform. The combined weight of the cryostat section and its transport vehicle calls for airfield-grade paving materials. While regular roads have a load-bearing capacity of 5 tonnes per cubic metre, the surface in front of the Cryostat Workshop needs to withstand higher pressures of up to 20 tonnes per cubic metre. And like on airfields, the new pavement also has a higher resistance for turning loads. A combination of specially designed materials ensures that the road surfacing—while only 15 centimetres thick—has the required properties. The compacted 11-centimetre-thick base layer consists of Optibase, an asphalt of a particular formulation developed for heavy-load roads. This has been topped with a thin layer of highly permeable asphalt. In a final step, workers spread a reinforcing concrete grout across the entire asphalt surface, allowing it to seep into all the cracks and open spaces. The surface in front of the Cryostat Workshop is now ready for the relocation of the lower cylinder to the nearby storage area, making space for the upper cylinder that will be assembled next. It is only the first area on the platform that has been upgraded to airfield-like tarmac. Other roads on the platform will follow suit in receiving this treatment once the work on the underground service networks in those areas has been completed. This will include the stretch of road near the Cleaning Building as well as the roads leading to the Poloidal Field Coils Winding Facility and around the cryoplant.

Photo report | Ring magnet fabrication in full swing

At least as wide as a five-lane highway, ITER's largest ring-shaped magnets are too big to be transported in their finished state. The European Domestic Agency has purpose built a facility at ITER to house their fabrication only a few hundred metres from machine assembly pit. This report will take you inside the building, where a team of 70 is advancing the fabrication of the first production unit—poloidal field coil #5 (PF5). Six ring-shaped poloidal field coils will be positioned horizontally outside of the toroidal field magnet system to shape the plasma and contribute to its stability by "pinching" it away from the walls. Of the six coils—which range in diameter from 17 metres to 24 metres, and in weight from 200 to 400 tonnes—the European Domestic Agency, Fusion for Energy, is responsible for five. (A sixth is under the procurement responsibility of Russia.) In the facility on site, work on PF5 is 42 percent completed. See the gallery below and a full report on the European Domestic Agency website.

of-interest

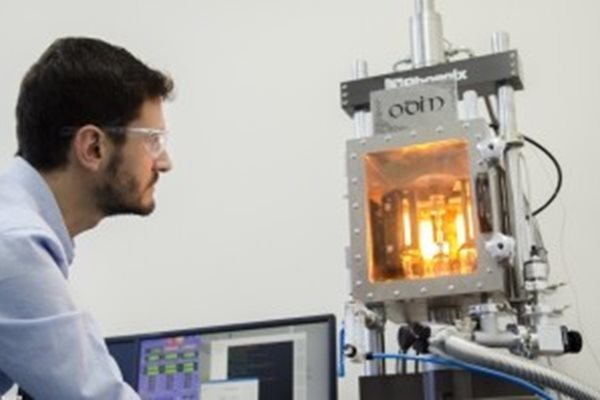

UK fusion centre/university collaborating on materials

As part of an investment made last year by the UK Atomic Energy Authority (UKAEA) to launch a fusion technology platform at the Culham Centre for Fusion Energy (CCFE), the 'Fusion Technology Facilities' (FTM) centre of excellence will house a suite of equipment designed to test fusion components under combined thermal, mechanical, hydraulic and magnetic loads representative of future fusion power stations. In the build-up period, the team is establishing links to promote knowledge sharing and to support an ambitious industry-related research program. CCFE has just announced that a strong collaboration is planned between the Materials Technology Laboratory at FTM and the Department of Mechanical Engineering at the University of Bristol (UK). The establishment of complementary test equipment at Bristol and the funding of a joint post-doctoral research position are part of the agreement. Read more at CCFE and the University of Bristol.