Bring in the welders

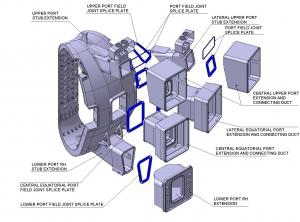

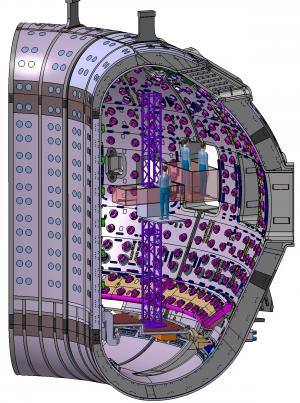

ITER's vacuum vessel is a torus-shaped, double-walled structure made out of 60-mm-thick, ITER-grade austenitic stainless steel. The vacuum vessel will be manufactured in nine sectors (two by Korea and seven by Europe) and delivered to the ITER site. The nine vacuum vessel sectors will be sub-assembled with thermal shielding and toroidal field magnet coils before being positioned in the machine pit by crane.

The work on the vacuum vessel and the ports will be done in accordance with RCC-MR (Design and Construction Rules for Mechanical Components of Nuclear Installations, 2007) and the ITER Vacuum Handbook.