What it takes to wire up a fusion reactor

While the challenges of keeping cables operational in harsh environments such as jet engines and nuclear fission reactors have been understood for a long time, protecting cables inside fusion reactors is a different story. Fusion presents a new set of challenges—challenges that can only be overcome with a new round of innovation.

"If the diagnostics are the eyes of the project, the electrical systems are the nerves," says Matt Clough, vacuum electrical engineer for the In-Vessel Diagnostics Section. "The electrical systems provide the power and signal paths for the diagnostic systems to take the measurements and report back."

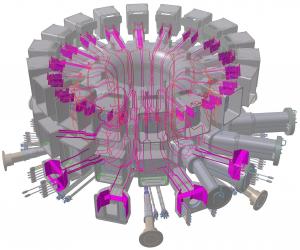

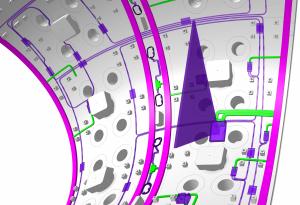

Cooling the cables is complicated due in part to sheer volume—about 3,800 signal lines from a variety of diagnostic and operational instrumentation clients and in every sector of the vessel, according to Clough. "We're very limited for space, so we have to bundle them together (up to 36 cables) to form over 100 cabling "looms"—and keep them cool at the same time. We don't have cooling pipes in the looms, but we can make use of the fact that the vessel itself is water-cooled. So the heat from every single cable in the bundle has to be transferred to the vessel wall—and that turns out to be very tricky."

Cabling requirements for every diagnostic client had to be agreed years in advance, so that cables could be developed, manufactured and installed in time for First Plasma. The teams has also had to consider cross talk—the electrical noise induced between the conductors inside of the same cable. "We studied and tested a variety of cable geometries—that is, the disposition and separation of the copper cores within the cables—to understand which one had a better cross-talk performance," says Pérez-Lasala.

"Because we have to order the cables to a specific length, the routing of every single cable has to be modeled in 3D," says Clough, acknowledging the thousands of hours of painstaking work performed by C3D. "Every cable, clamp and clip is drawn, because we have to know the cable length to millimetre precision. The fact that we can't shorten or lengthen cables on-site also means we have to model upfront ways to accommodate a vessel that is not yet fully assembled."

"We have many thousands of individual cables to deal with, including the ones being procured by Fusion for Energy under the current contract," says Clough. "And we have to make sure we have reliability all along the signal chain. We're facing a unique set of challenges that are different even from other fusion experiments. Other tokamaks either don't have as many cables as we have, or they have fewer restrictions on the materials they can choose, or how the cables can attach to their vessel."