Marvels of the subterranean world

The amount of power that must be delivered to the transformers, rectifiers, converters and other exotic devices that will feed DC current to the magnets and other "ITER specific" systems is equivalent to the production capacity of a medium-sized thermal power plant (~500 MW at peak pulse). This huge quantity of electrical power is distributed throughout the platform, from the converters that step down the grid's voltage from 440 kV to 66kV and 22 kV, to the equipment inside dedicated buildings or installations. Thousands of kilometres of armored cables, running below ground in a maze of galleries, are tasked with the delivery. As the installation of the 66 kV cables progresses between the electrical switchyard and the twin magnet power conversion buildings, we explored this strange subterranean world.

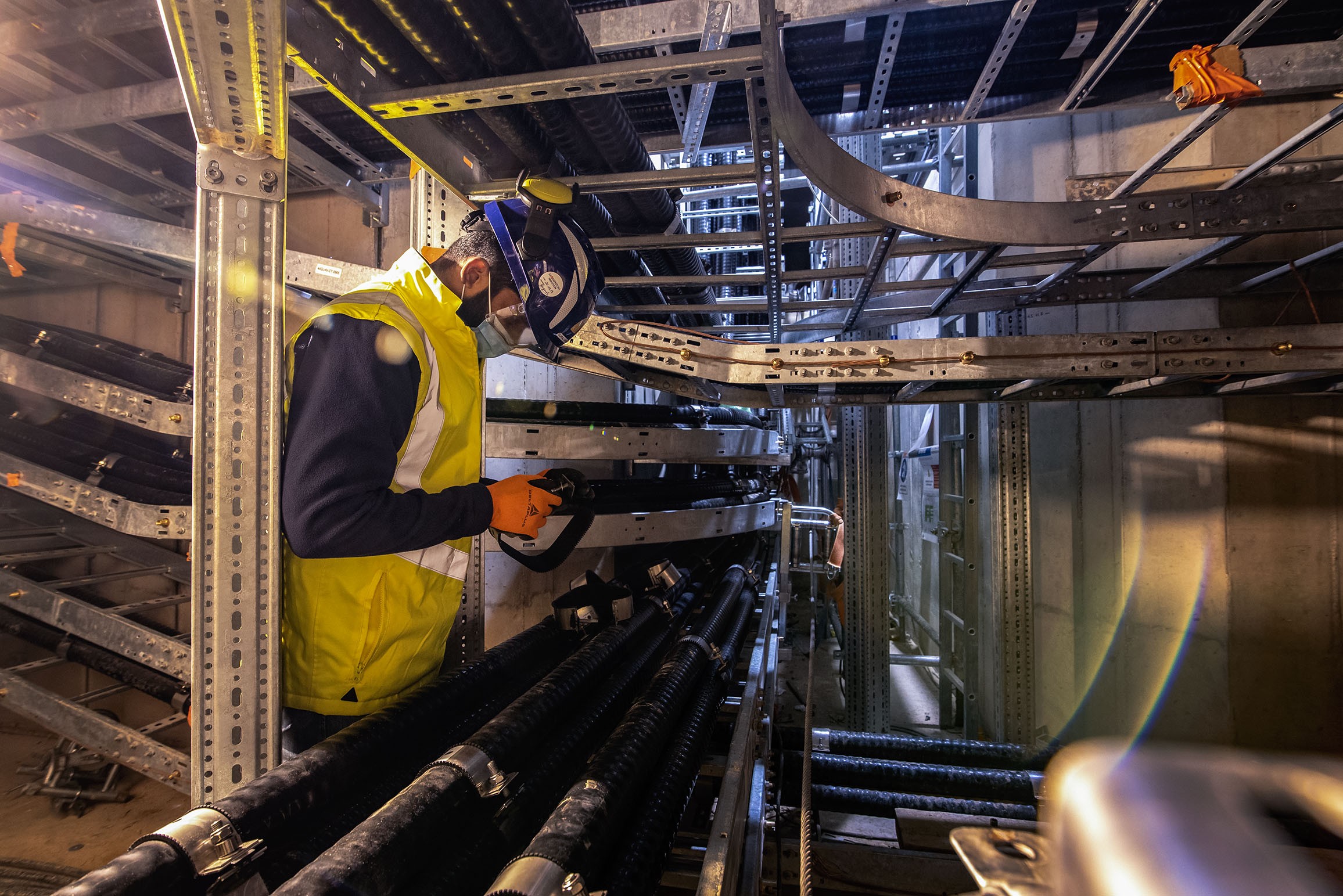

The manhole is narrow and the ladder is steep. We are descending into the "cathedral," a high-ceilinged space approximately 8 metres tall, almost totally occupied by rack after rack of cable trays.

Each tray supports up to nine cables, each one as thick as an arm. In certain places, where the cables bend towards the surface, the impression is that of tentacles belonging to a creature lurking in the depths.

From the "cathedral," located below the west entrance of the magnet power conversion buildings, cables head in all directions, eventually reaching the four corners of the platform.

Since July 2020, workers have been busy installing the 66 kV cables that connect the converters in the electrical switchyard (where the 66 kV network originates) to the equipment inside the magnet power conversion buildings. Along this 150-metre distance, work is now 60 percent complete; it will be finalized in another six to seven months.

Procured by China, the cables are delivered in drums and unspooled by a powerful winch located at the opposite end of the gallery. All along the underground pathway, contractors from the Slovakian company Busbar 4F are monitoring the operation, guiding the cables along rollers and into their dedicated trays. The pulling force exerted by the winch is proportional to the length of cable already unspooled, reaching the equivalent of 50 to 60 workers at its strongest. Fifty drums, each carrying 4.7 tonnes of cable, have been unspooled so far.

Each cable carries a 600 Amp current and there are two cables per phase—which makes six cables per converter. With 26 hungry converters and a few auxiliaries to feed, the 66 kV network requires 216 individual cables, 150 of which have already been installed.

Once the total cable length is pulled, one end close to the equipment in the conversion buildings and the other in the electrical switchyard, it can be connected to the converters. Prior to connection, the view is striking—the hidden creature having now extended its tentacles all the way to the surface.

When the required 53 kilometres of 66 kV cables are installed, similar operations will be conducted for the 22 kV network, which is shorter (41 kilometres) and comprises "only" 114 cables of a slightly smaller diameter.

See the gallery below for more information.