La première (sur 18) est en place

Dix-huit bobines de correction, dont six bobines supérieures, six bobines latérales et six bobines inférieures, agiront par paires pour corriger ou atténuer les anomalies de champ les plus problématiques. L'agence domestique chinoise et son prestataire ASIPP (l'Institut de physique des plasmas de l'académie des sciences de Chine) sont chargés de fournir ces bobines, qui ont été conçues par ITER Organization. Les deux premières bobines de correction inférieures sont arrivées sur le site d'ITER au mois de décembre 2020. Depuis, quatre autres bobines inférieures ont également été livrées.

Chaque bobine est soumise à des procédures de réception sur site, qui incluent notamment des contrôles électriques, des relevés dimensionnels, des essais d'étanchéité et des contrôles de soudures. Les essais des bobines inférieures BCC/4 et BCC/5 ont été achevés ce mois-ci.

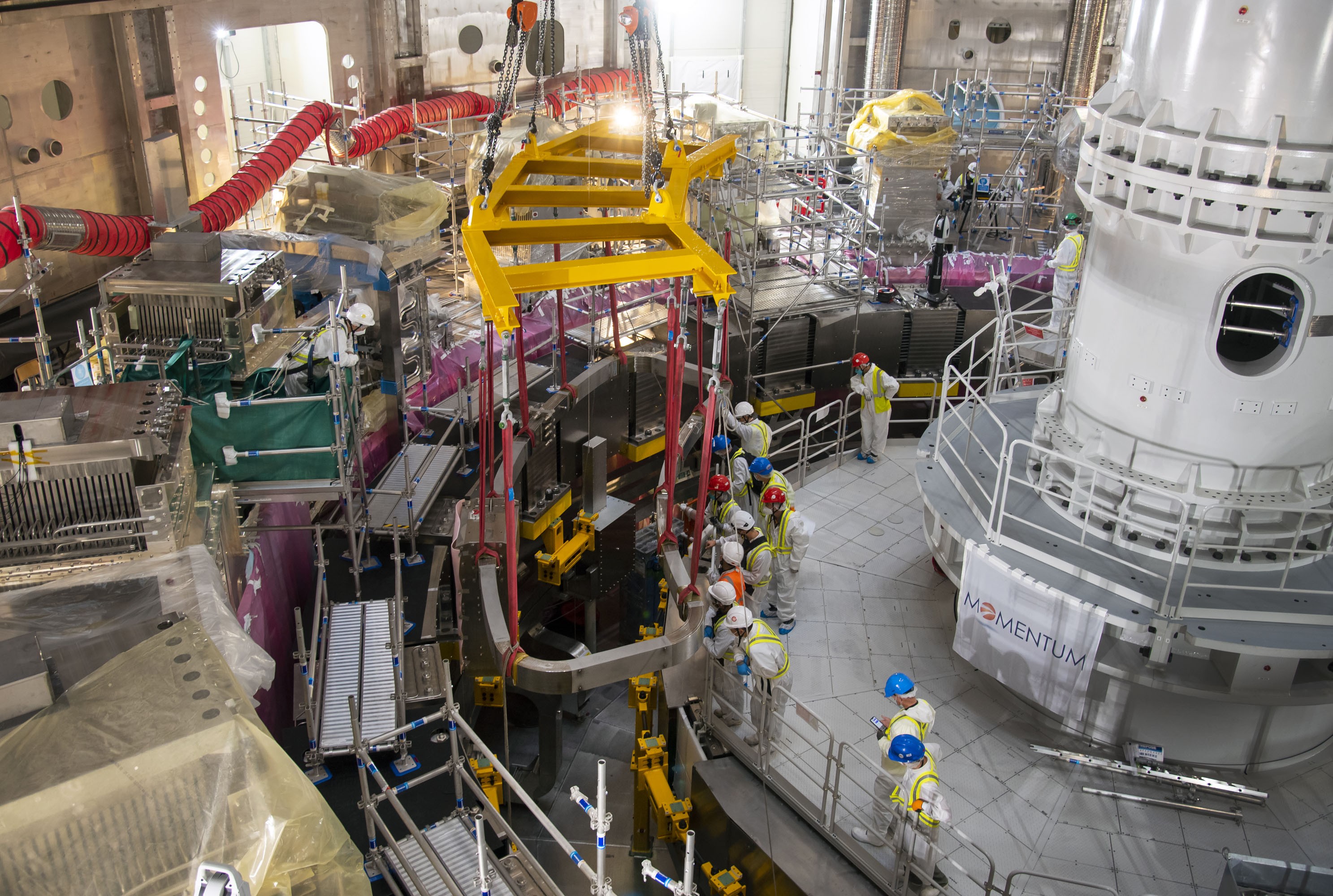

« Nous connaissons l'emplacement final des deux premières bobines de champ poloïdal dans la fosse. Nous avons donc travaillé à partir de ces informations pour préparer les supports provisoires et planifier l'opération de levage, explique Josep Pallisa, ingénieur en charge de l'assemblage au sein du département Aimants. Le fond de la fosse du tokamak étant déjà très encombré, les bobines de correction inférieures et leurs supports doivent s'insérer dans un espace restreint entre la bobine de champ poloïdal n°6, la bobine de champ poloïdal n°5, les systèmes d'alimentation des aimants inférieurs et les plateformes d'installation. »

Le levage de la bobine de correction BCC/4, le jeudi 21 octobre, s'est déroulé comme prévu. La deuxième bobine, la BCC/5, sera mise en place dans la fosse le 26 octobre et deux autres paires de bobines de correction inférieures les rejoindront dans les mois qui viennent. Dans la configuration finale de la machine, les bobines de correction seront fixées sur la superstructure des bobines de champ toroïdal.