Encore deux !

À l'extrémité sud de la vaste installation de fabrication, un enroulement de 16 tonnes est extrait de son châssis de transport pour être inséré dans l'outil sur mesure qui dévidera les 900 mètres de conducteur gainé. Cette opération est la première étape du processus de fabrication des bobines, qui s'est déjà répétée 56 fois depuis la production des premières « maquettes », en 2016.

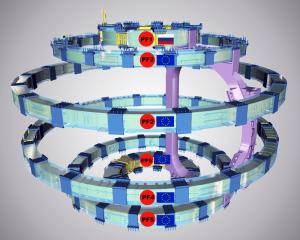

Fourni par la Chine et fabriqué par l'institut de physique des plasmas de l'académie des sciences de Chine (ASIPP), le conducteur est destiné à la bobine de champ poloïdal 3 (PF3). Pour former les « doubles galettes » utilisées dans la fabrication des bobines, des longueurs de conducteur sont prélevées simultanément sur deux enroulements (bobinage « en parallèle ») afin d'être dévidées, redressées, nettoyées puis cintrées selon l'angle souhaité et revêtues de ruban isolant. La bobine PF3, qui sera réalisée à partir de 8 doubles galettes empilées, nécessitera environ 14 kilomètres de câble.

Plus en aval sur la ligne d'assemblage, huit doubles galettes ont déjà été empilées pour la bobine de champ poloïdal 4 (PF4). Les équipes préparent la bobine pour l'isoler de la terre, une opération qui consiste à enrouler neuf couches successives de ruban en fibre de verre/Kapton autour de l'empilement afin d'assurer son isolation électrique.

Ces opérations délicates sont effectuées manuellement car les arrivées d'hélium situées à intervalles réguliers ne permettent pas d'automatiser le processus. Une fois isolé, le bobinage sera imprégné, équipé de colliers, de capots de protection, de tuyauteries, etc. puis soumis à des tests cryogéniques.

¹L'Europe est en charge des bobines de champ poloïdal 2, 3, 4, 5 et 6, la bobine PF1 étant fournie par la Russie. En raison des contraintes de calendrier et d'espace, la bobine PF6 a été fabriquée en Chine dans le cadre d'un contrat européen.