"Construction" Gallery

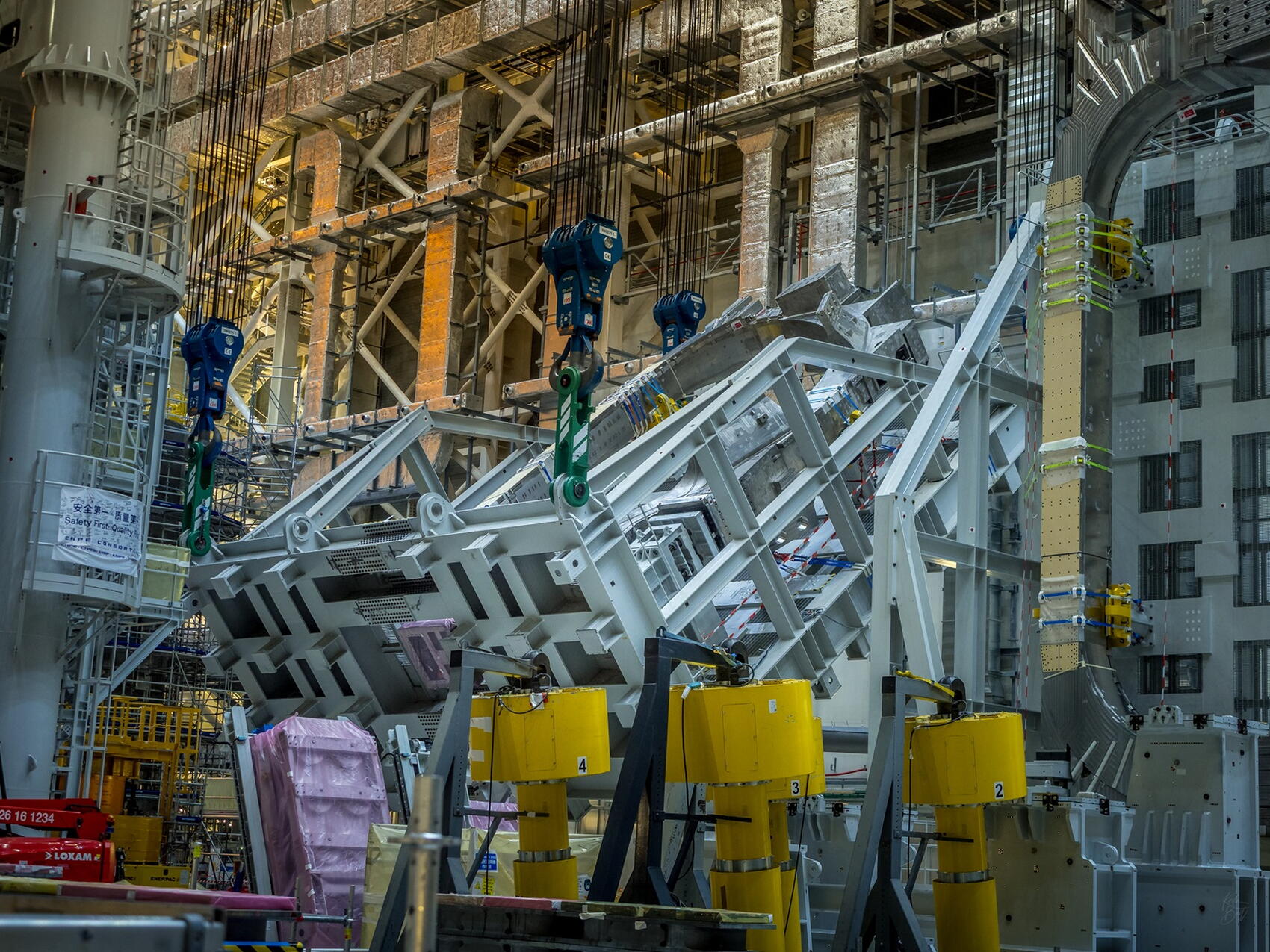

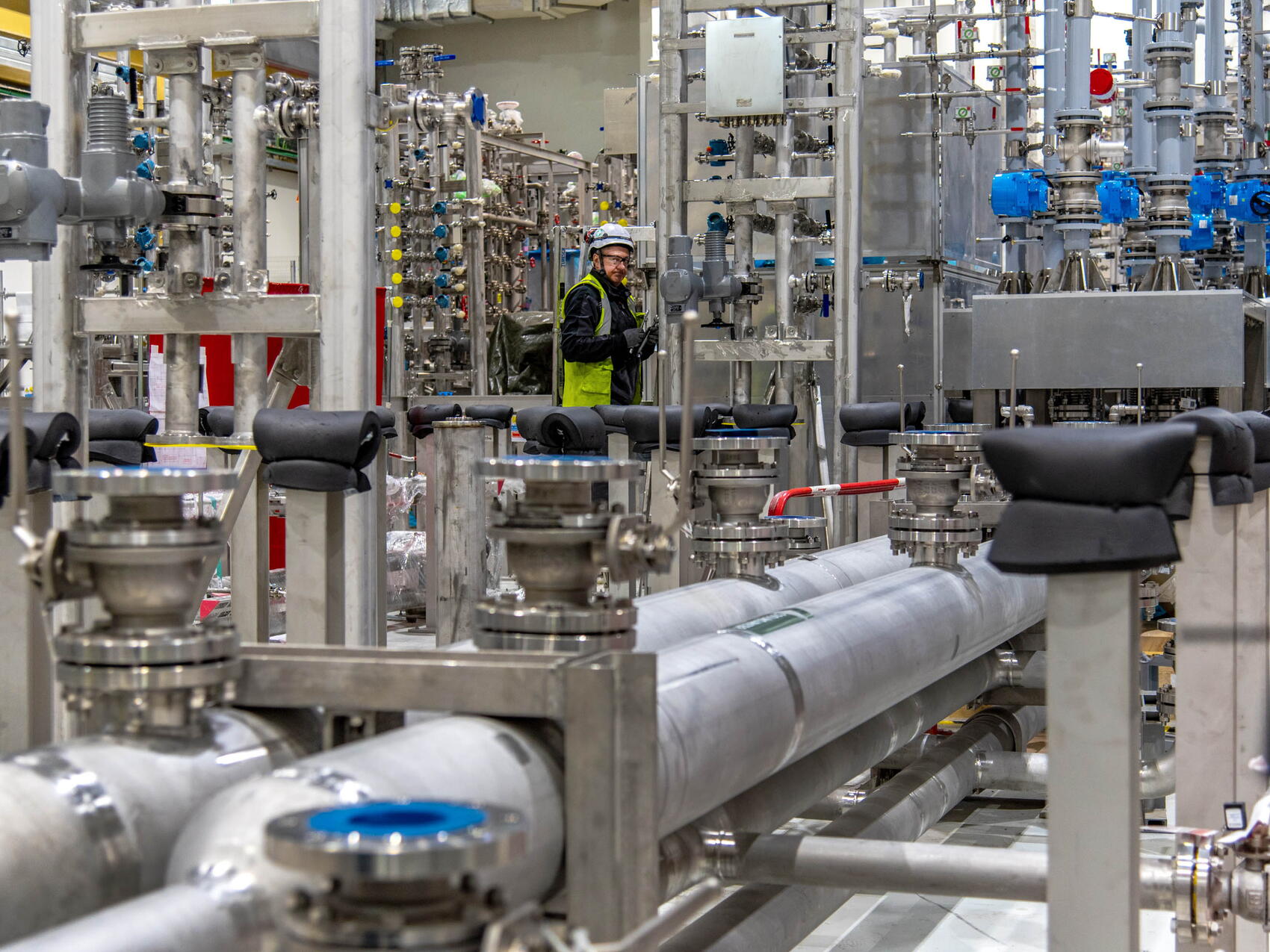

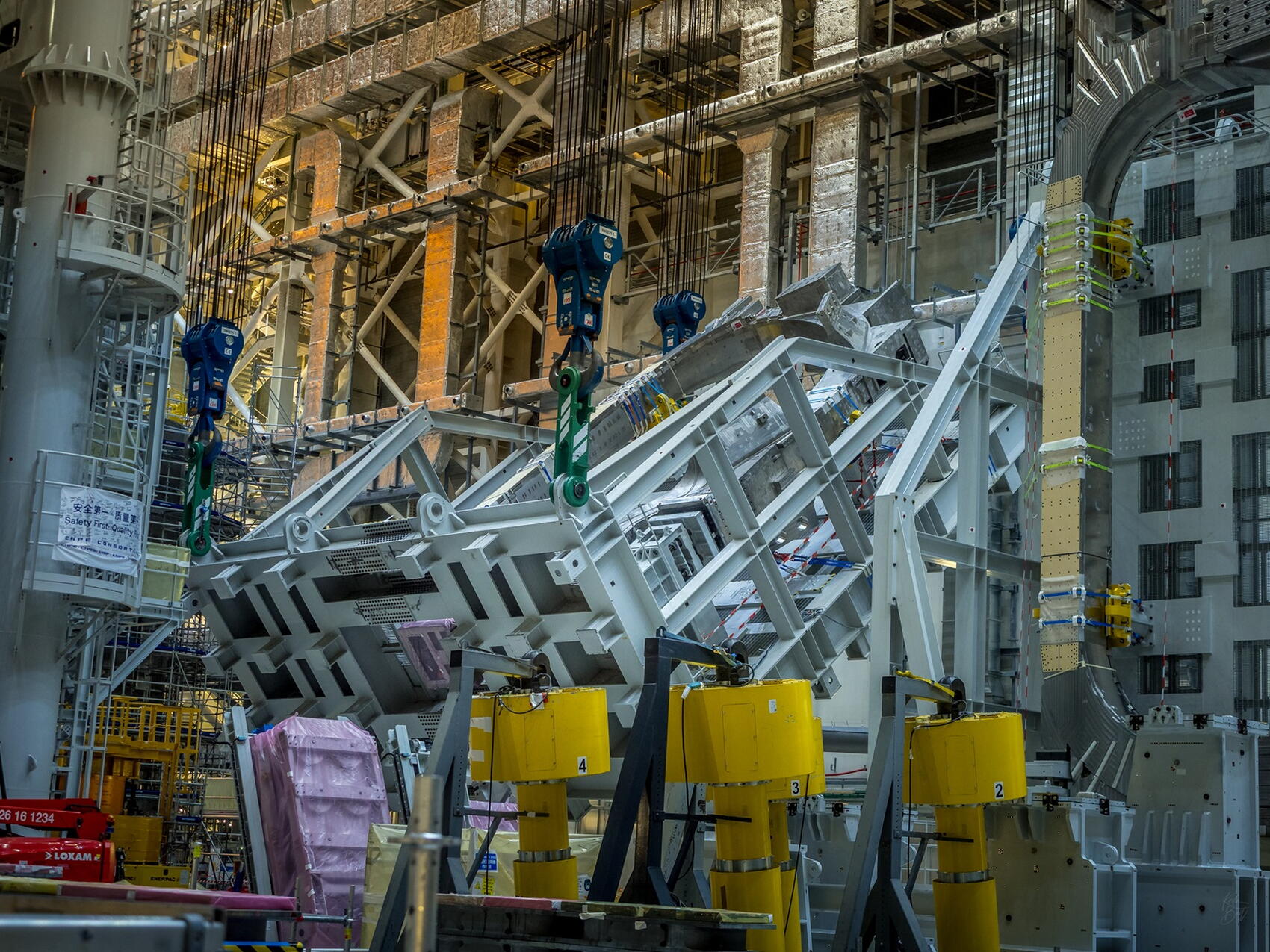

Cold valve box travelling

2026-02-19 - A smaller crane (capacity 50 tonnes) is used to move a plant component into the Tokamak Building through a temporary opening. This "cold valve box" will regulate the cryogenic fluids destined for different parts of the ITER thermal shield.

Watching closely

2026-02-19 - A technician watches closely as a 16-tonne plant component crosses overhead on its way to the Tokamak Building.

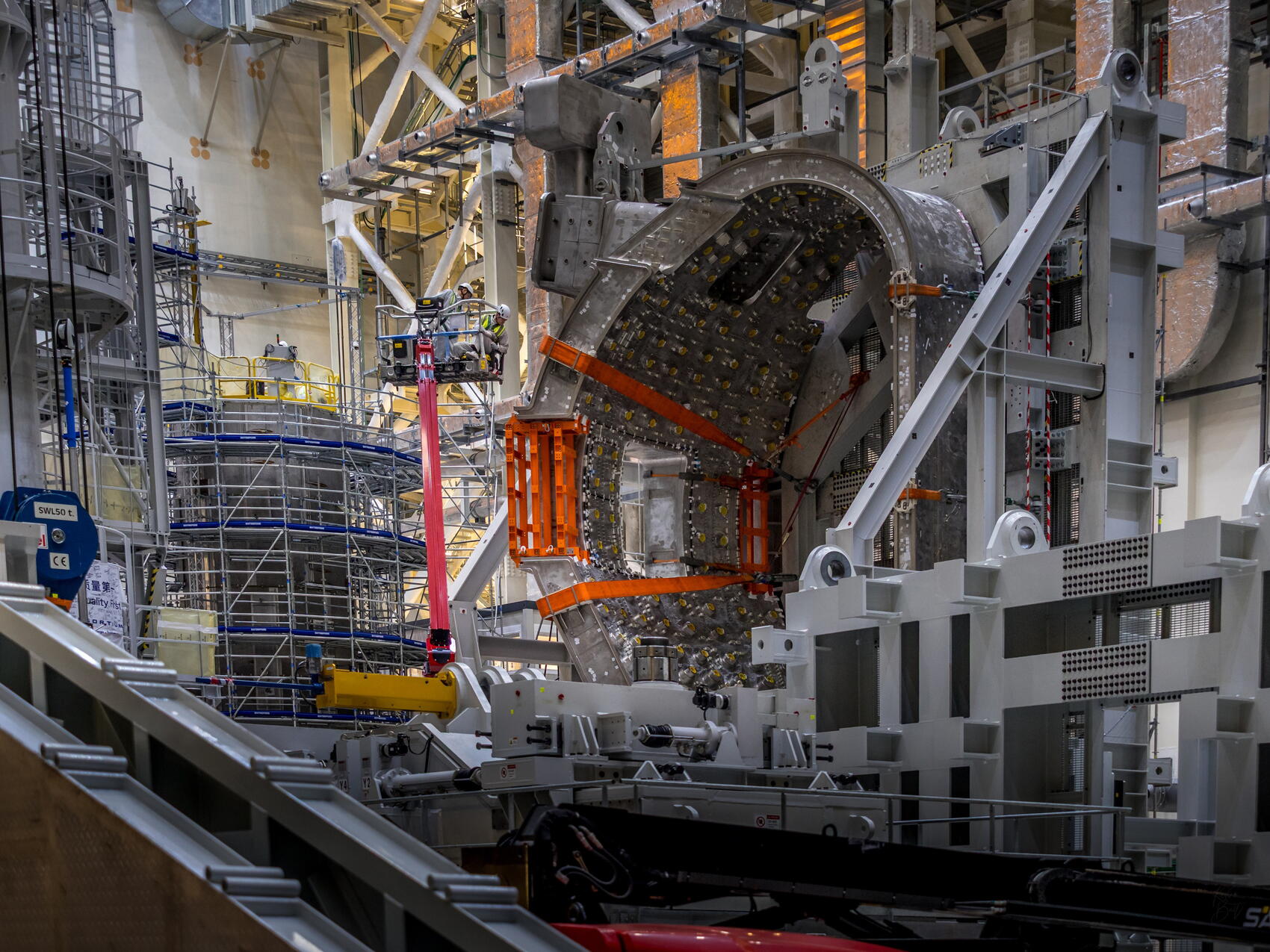

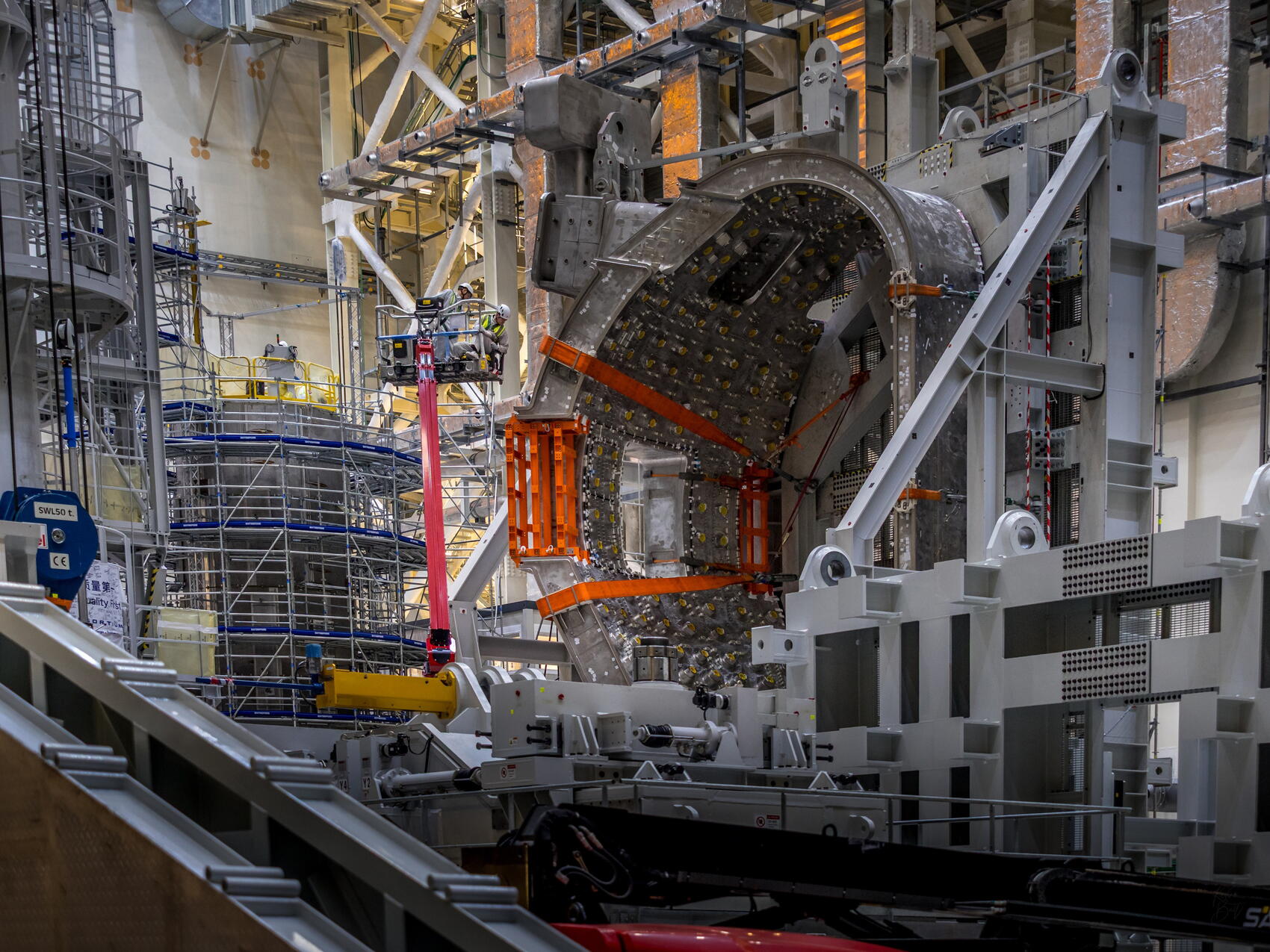

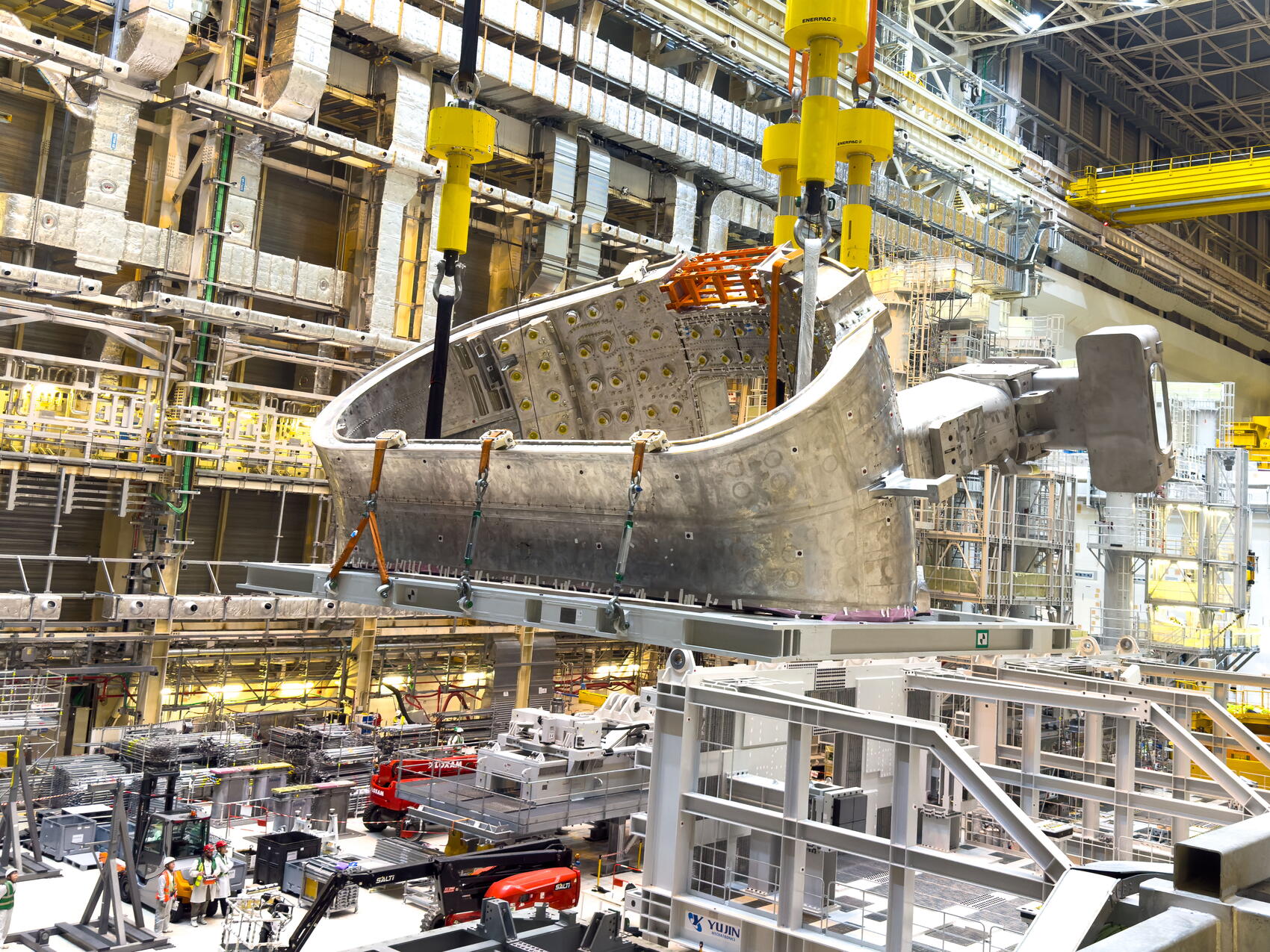

Approaching

2026-02-12 - The 400-tonne "bare" sector is transported over the transversal beam of the tall tool. Once it has been docked, work will begin to make it a "sector module."

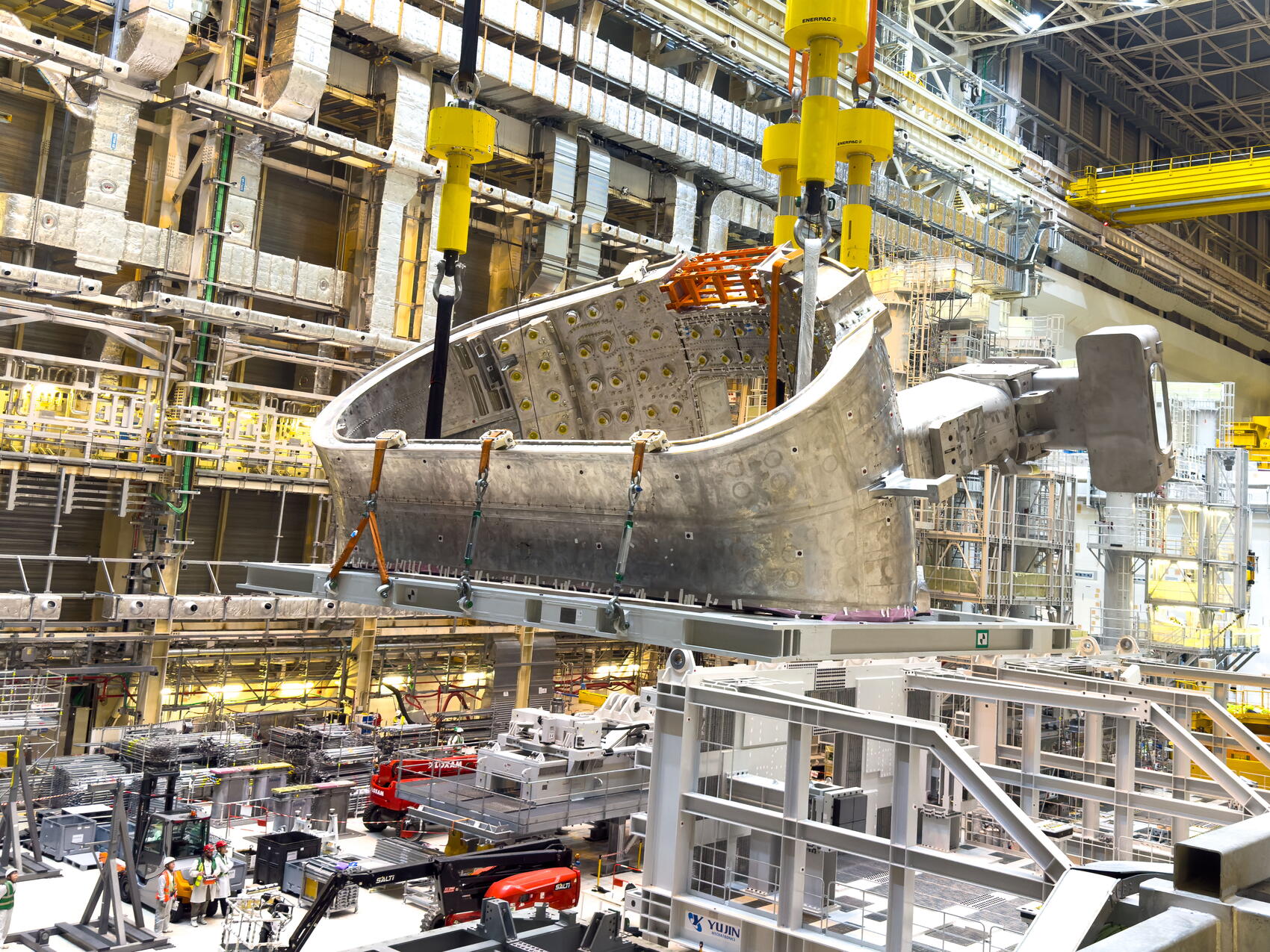

Nearly there

2026-02-12 - Vacuum vessel sector #1 is lowered into tooling by ITER's "pair of safe hands"—the 1,500-tonne bridge cranes.

Final prep

2026-02-12 - Final adjustments are underway for the imminent transfer of vacuum vessel sector #1 to assembly tooling.

Landed

2026-02-12 - Vacuum vessel sector #1 has landed in sub-assembly tool #2 (SSAT2). Its weight is supported by a radial beam (above) and a pillar under its lower port stub extension (below).

Gravity support transferred into pit

2026-02-11 - This vacuum vessel gravity support is one of nine that will be installed under the lower port stub extensions of each sector module in the pit.

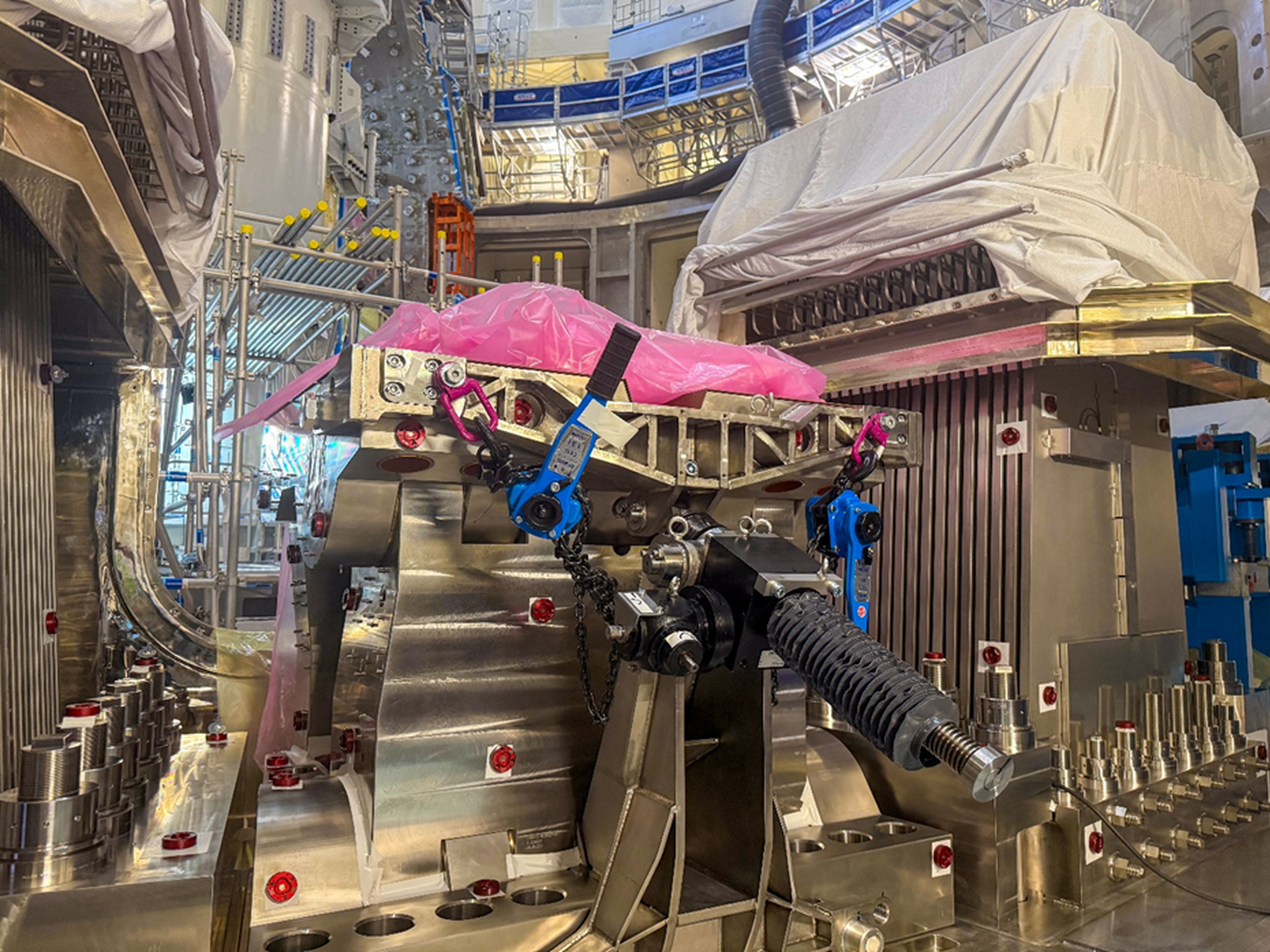

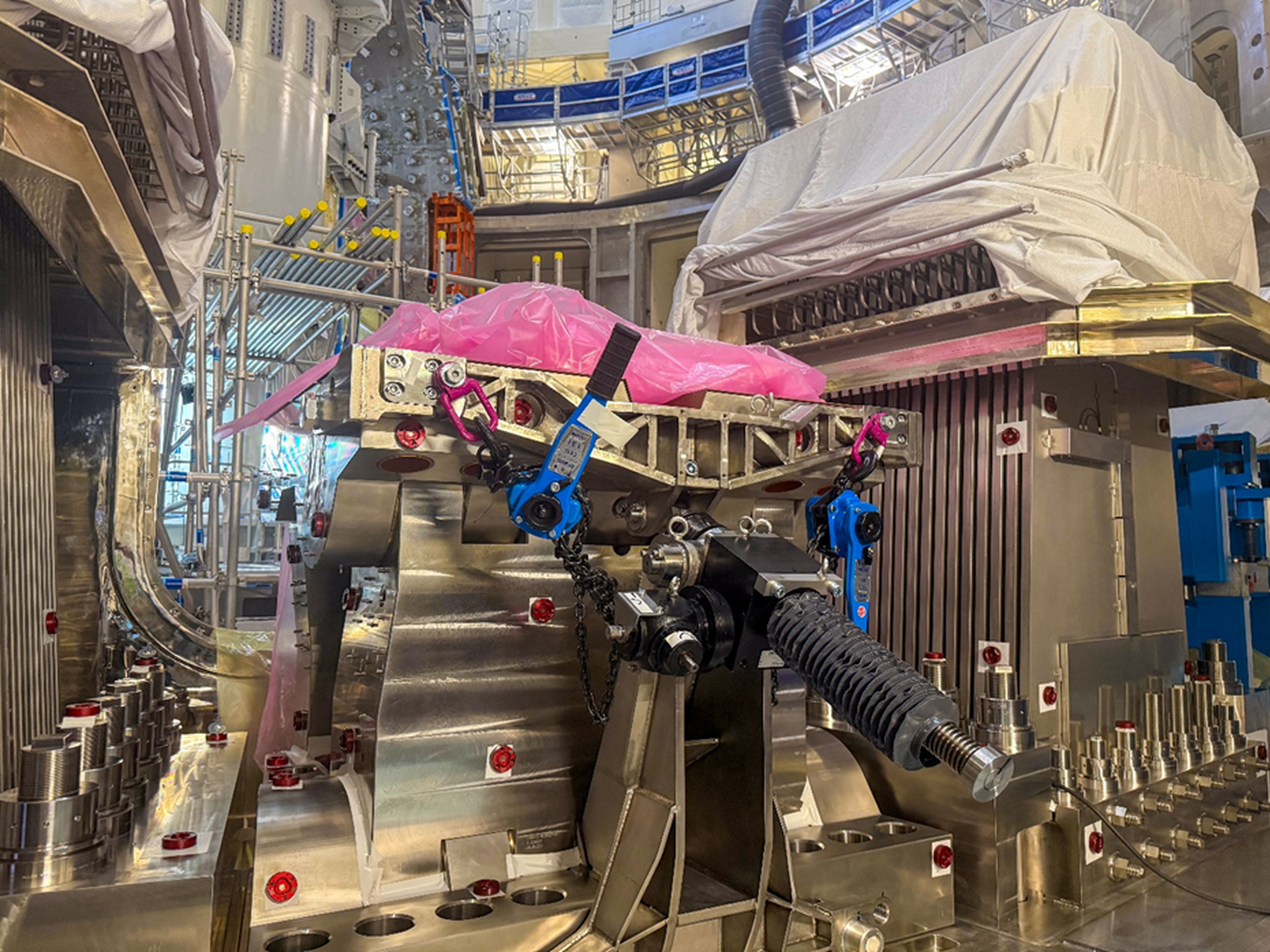

High-tech support

2026-02-11 - A (smaller) vacuum vessel gravity support is installed between two toroidal field coil supports with the help of a tool (in black) that helps to correct its angle of insertion. Both types of supports will shoulder heavy loads and also show some elasticity for different types of machine movement during operation.

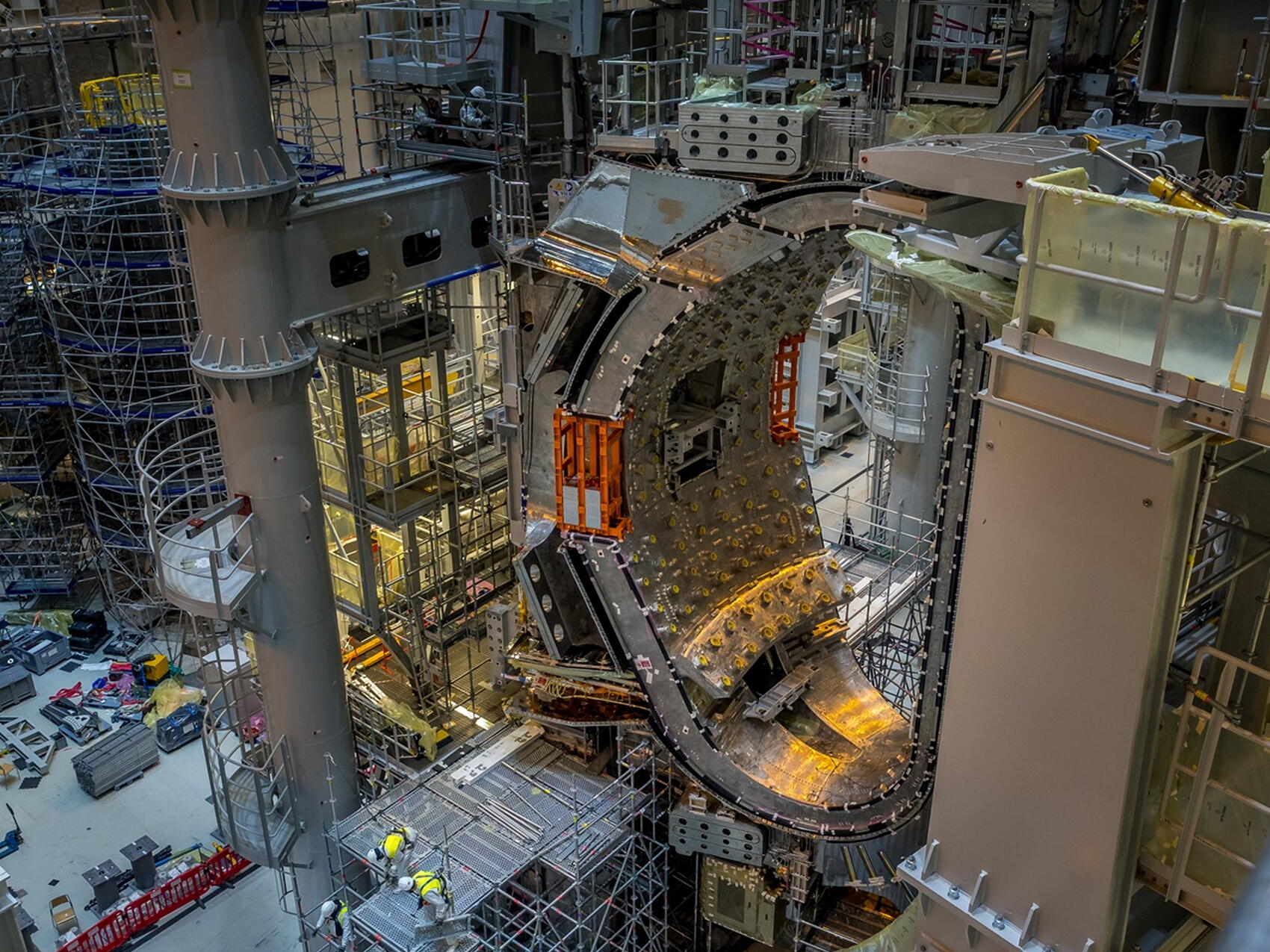

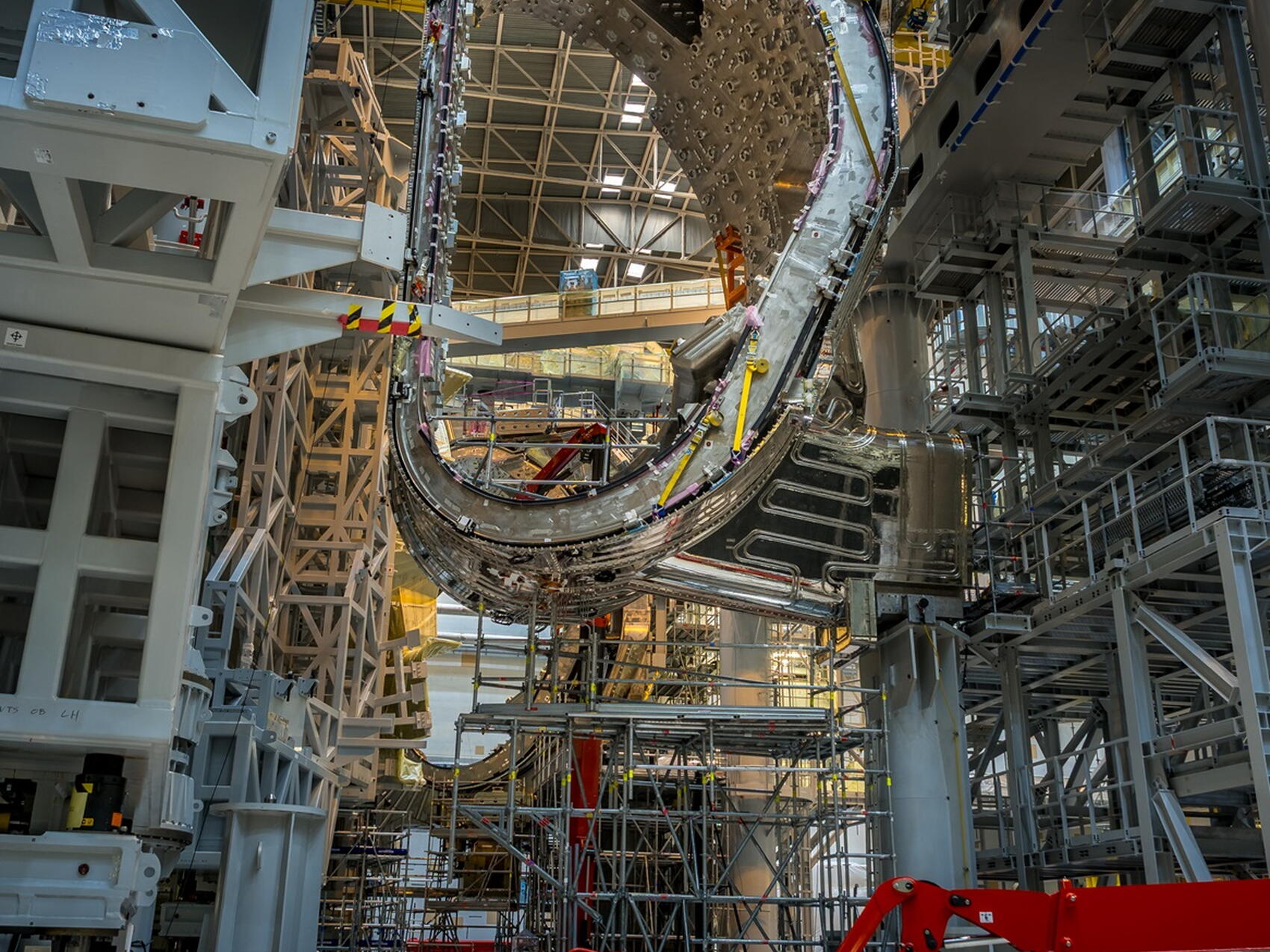

Majestic

2026-02-09 - Vacuum vessel sector #1 has been "upended" to vertical in the Assembly Hall. Later this week, the cranes will lift it out of the specialized frame and transfer it across the way where it will be assembled with other major components to become a "sector module."

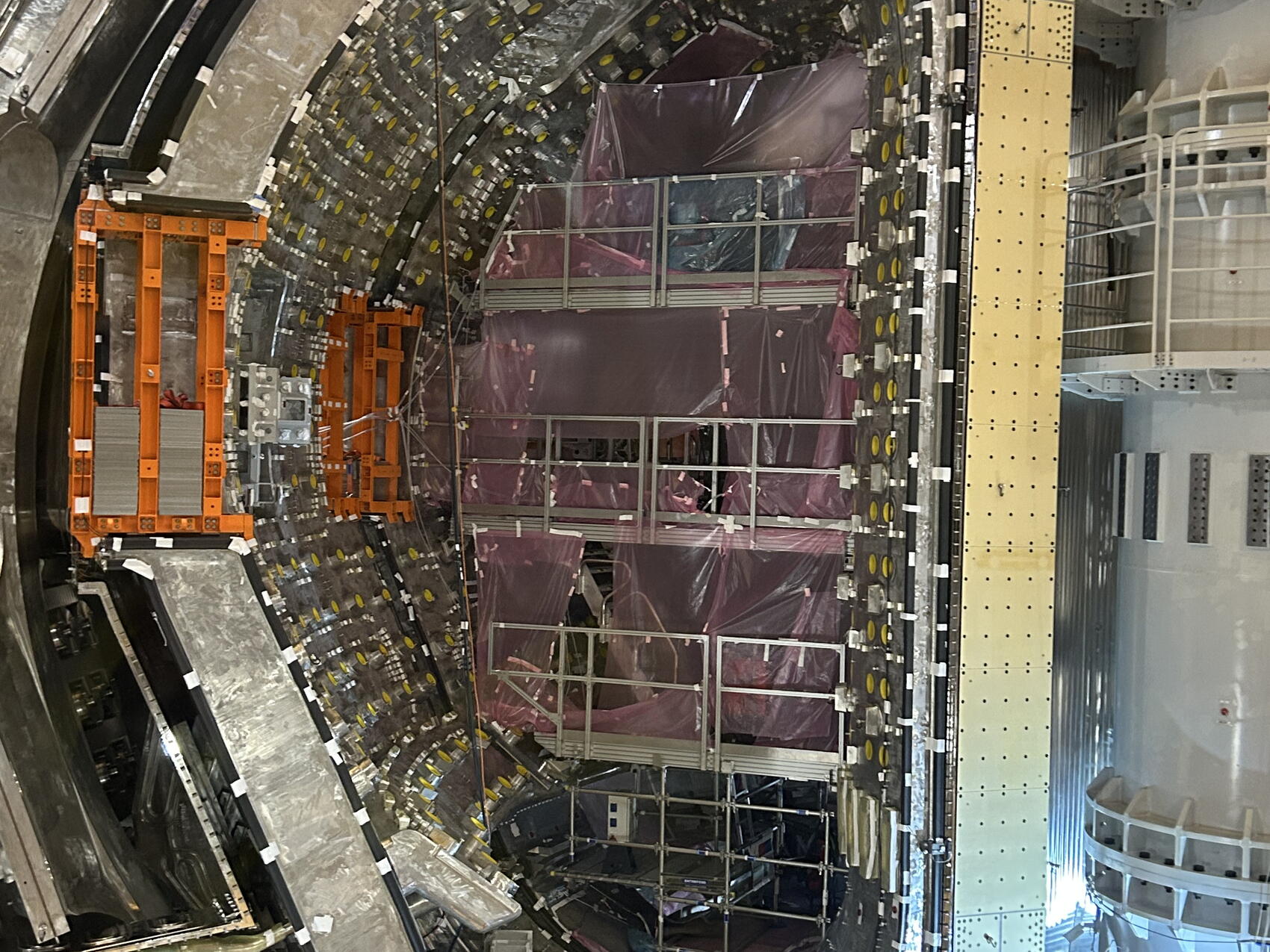

A space for trials and tests

2026-02-06 - This trial, training and test facility going up in one of the buildings on site reproduces three sectors of the vacuum vessel and one access port. When completed, it will be used to trial tools and train operators for the (many) types of activities required during the assembly of components on the inner walls of the vacuum vessel.

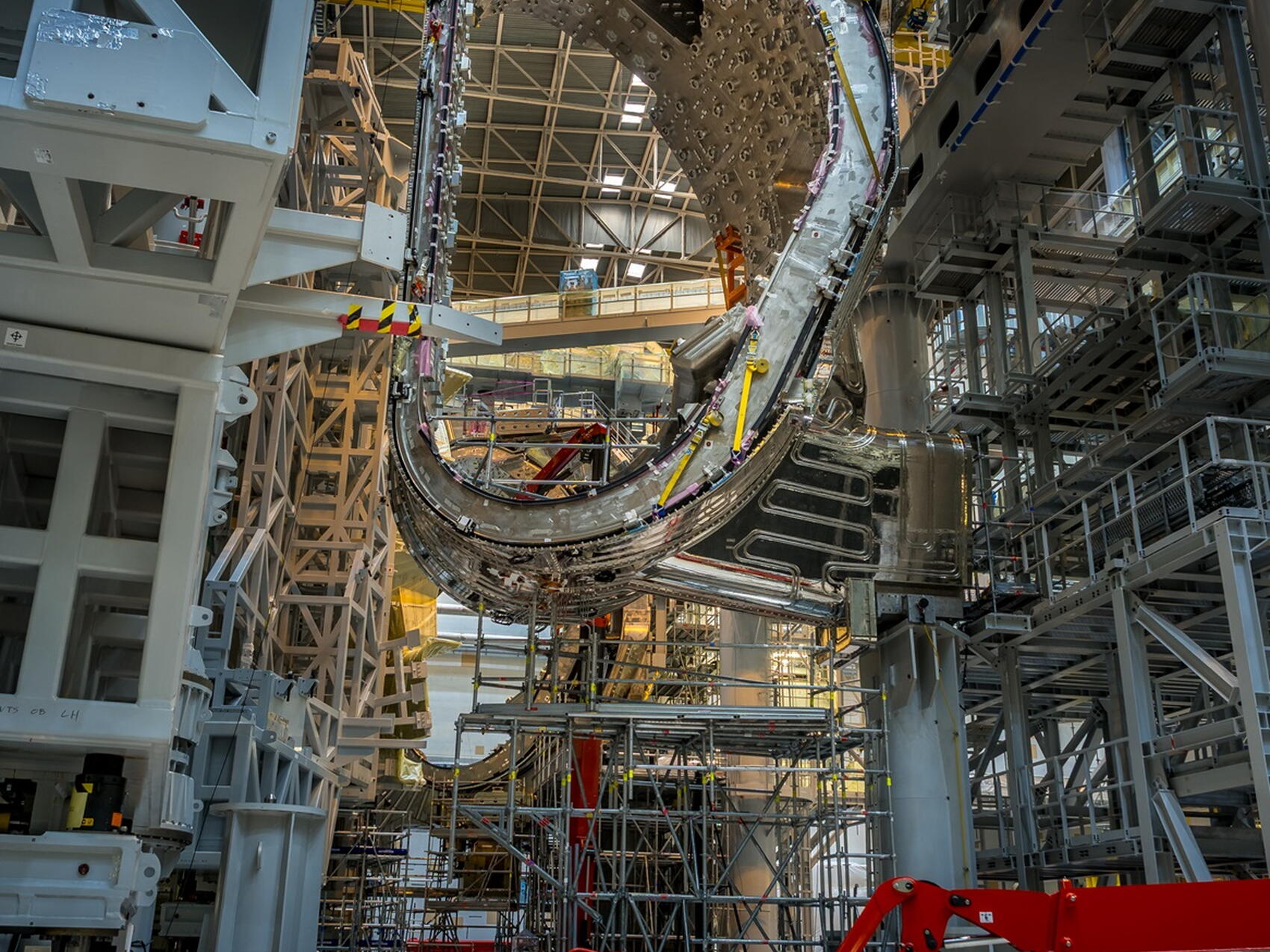

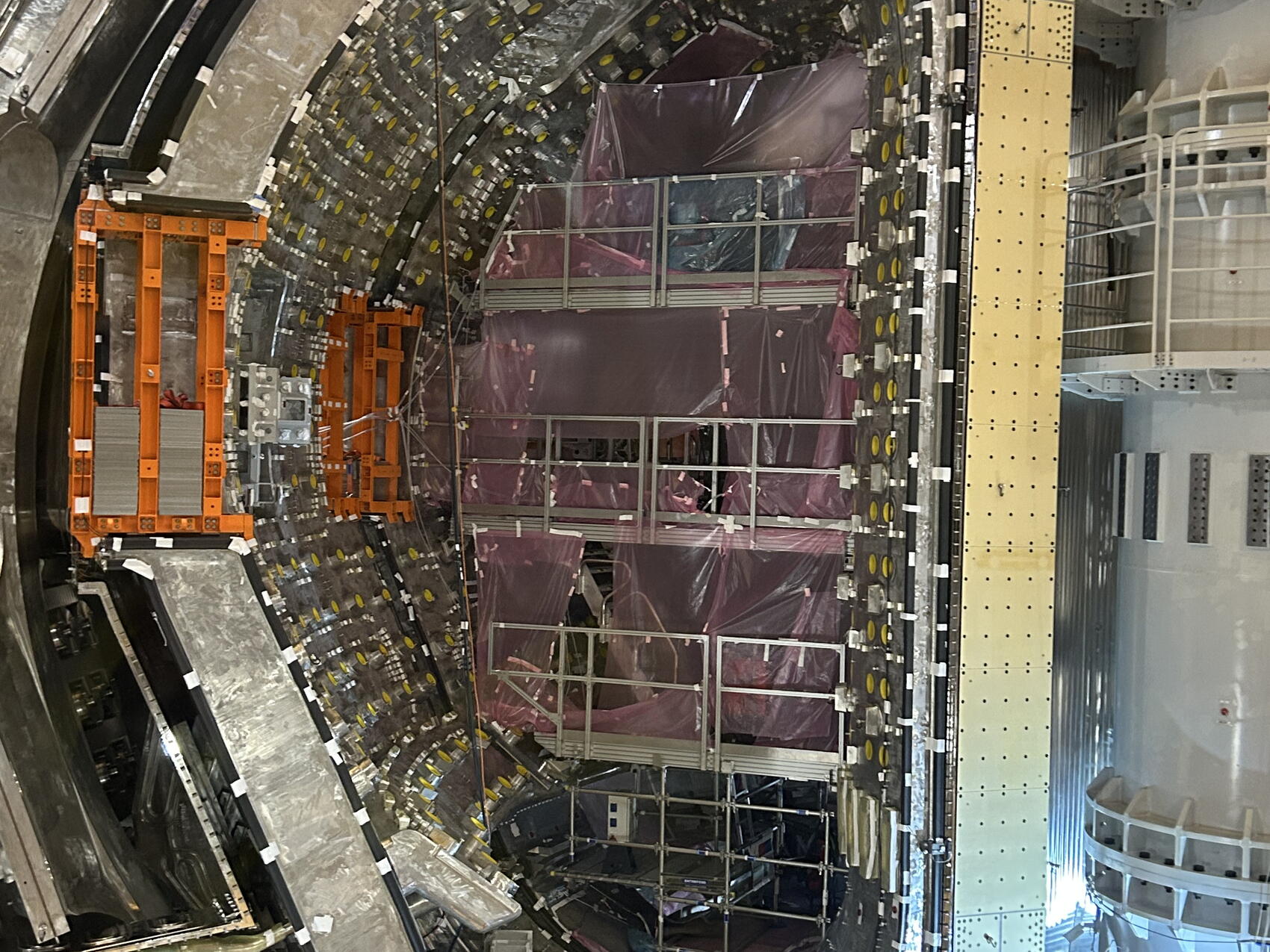

A shield around the sectors

2026-02-06 - An inboard thermal shield panel is lifted for transfer to vacuum vessel sub-assembly tooling. "Inboard" means that this panel will mounted on the portion of the vacuum vessel sector that is closest to the middle of the tokamak pit.

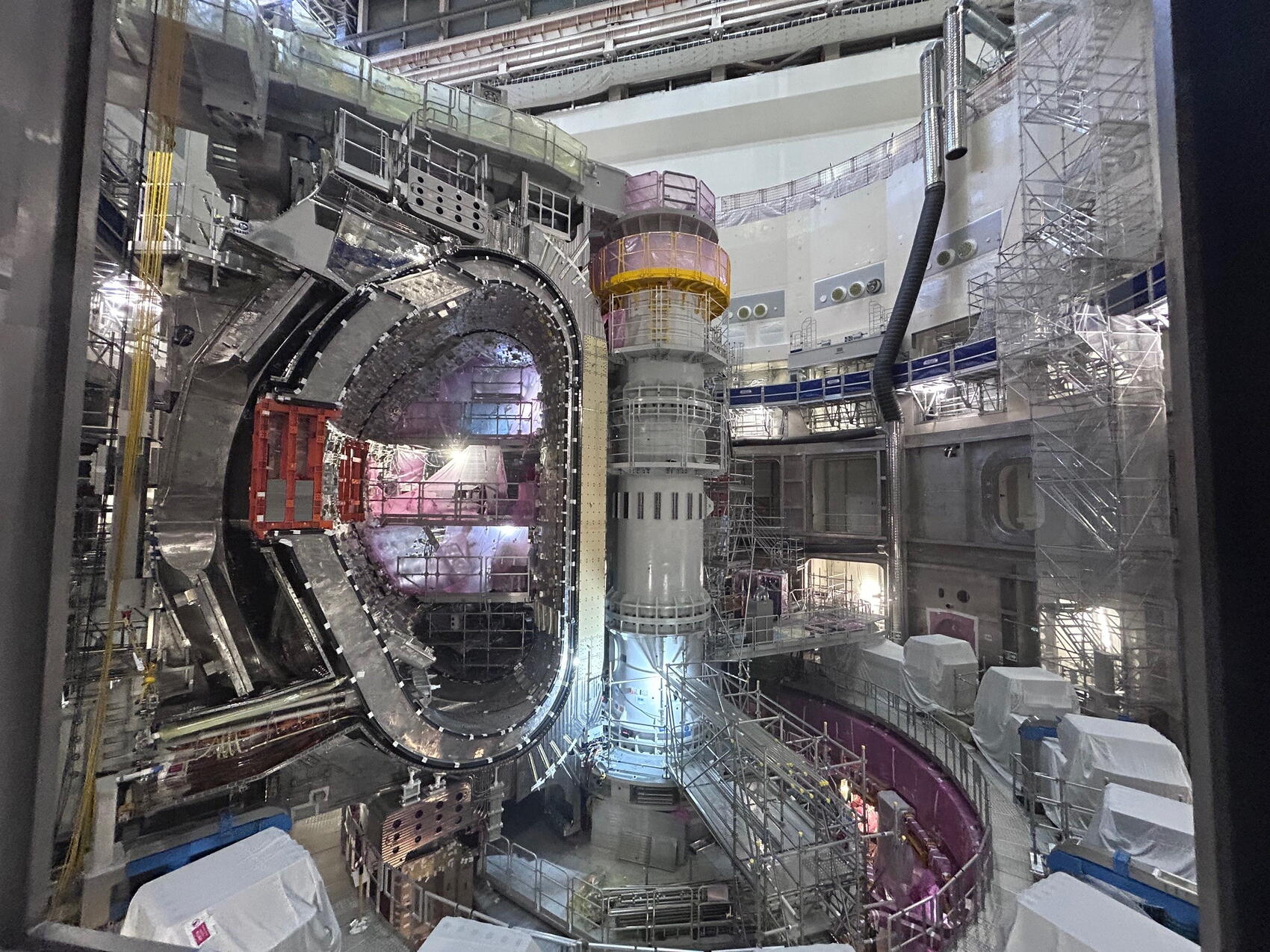

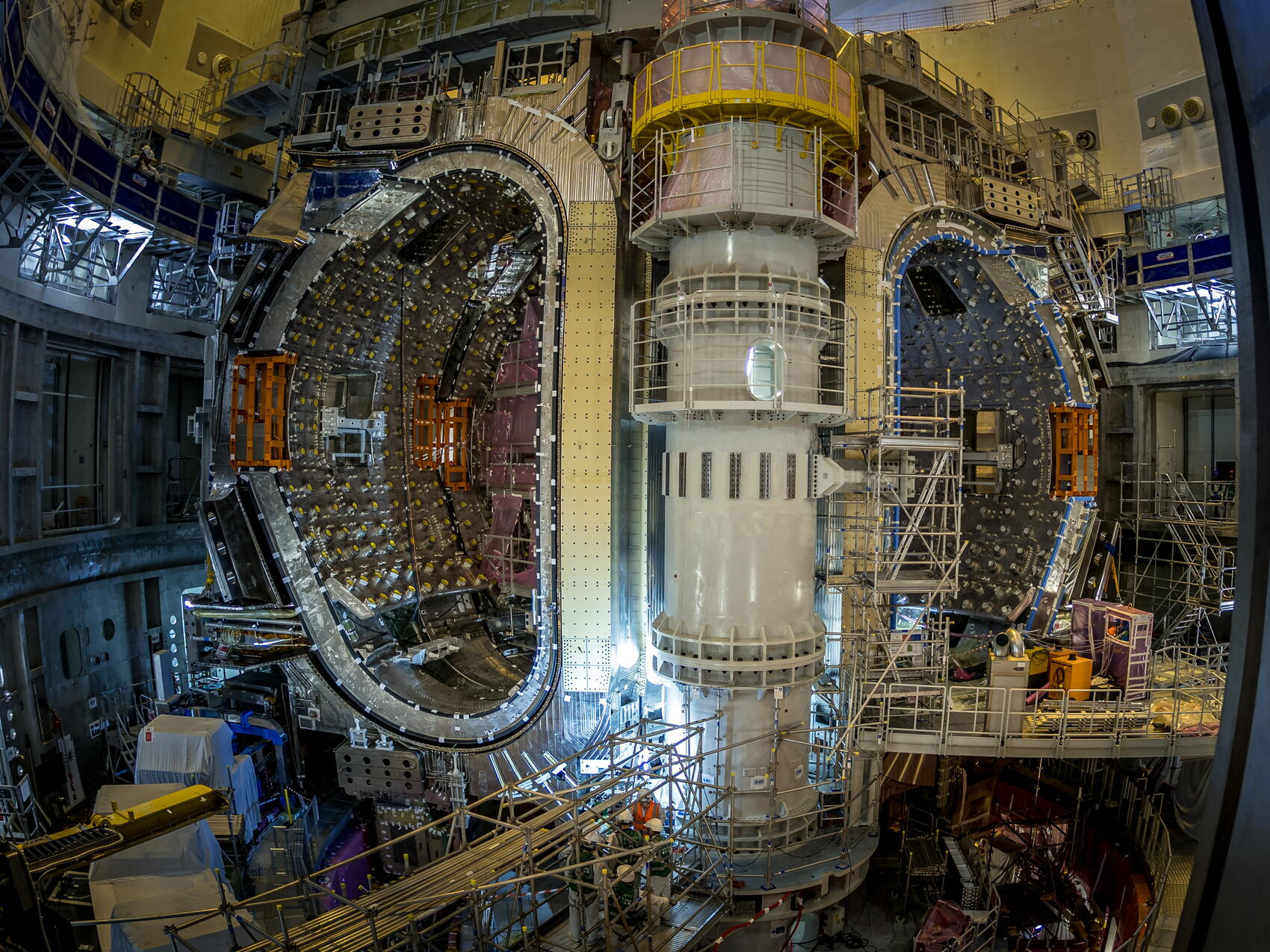

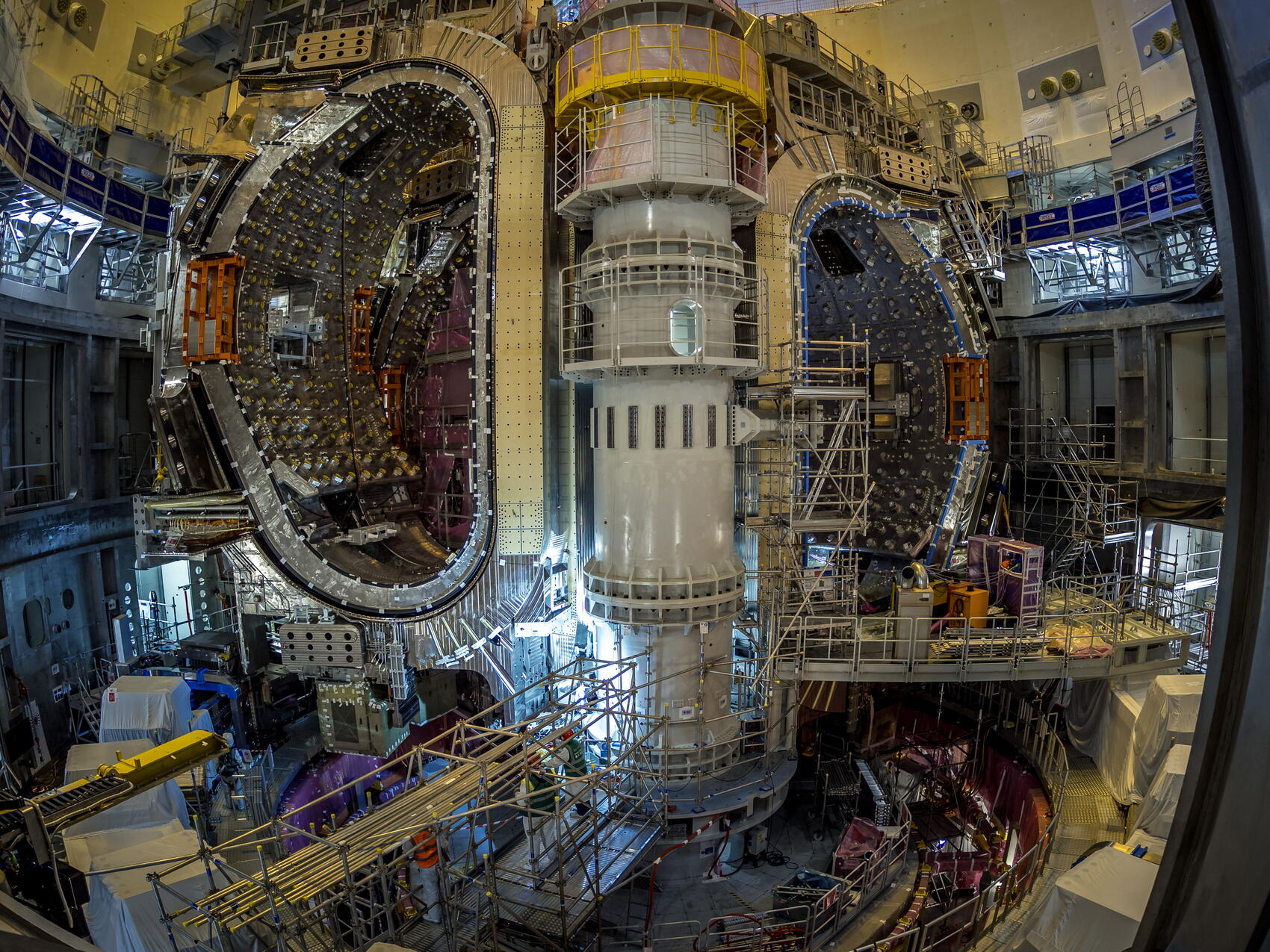

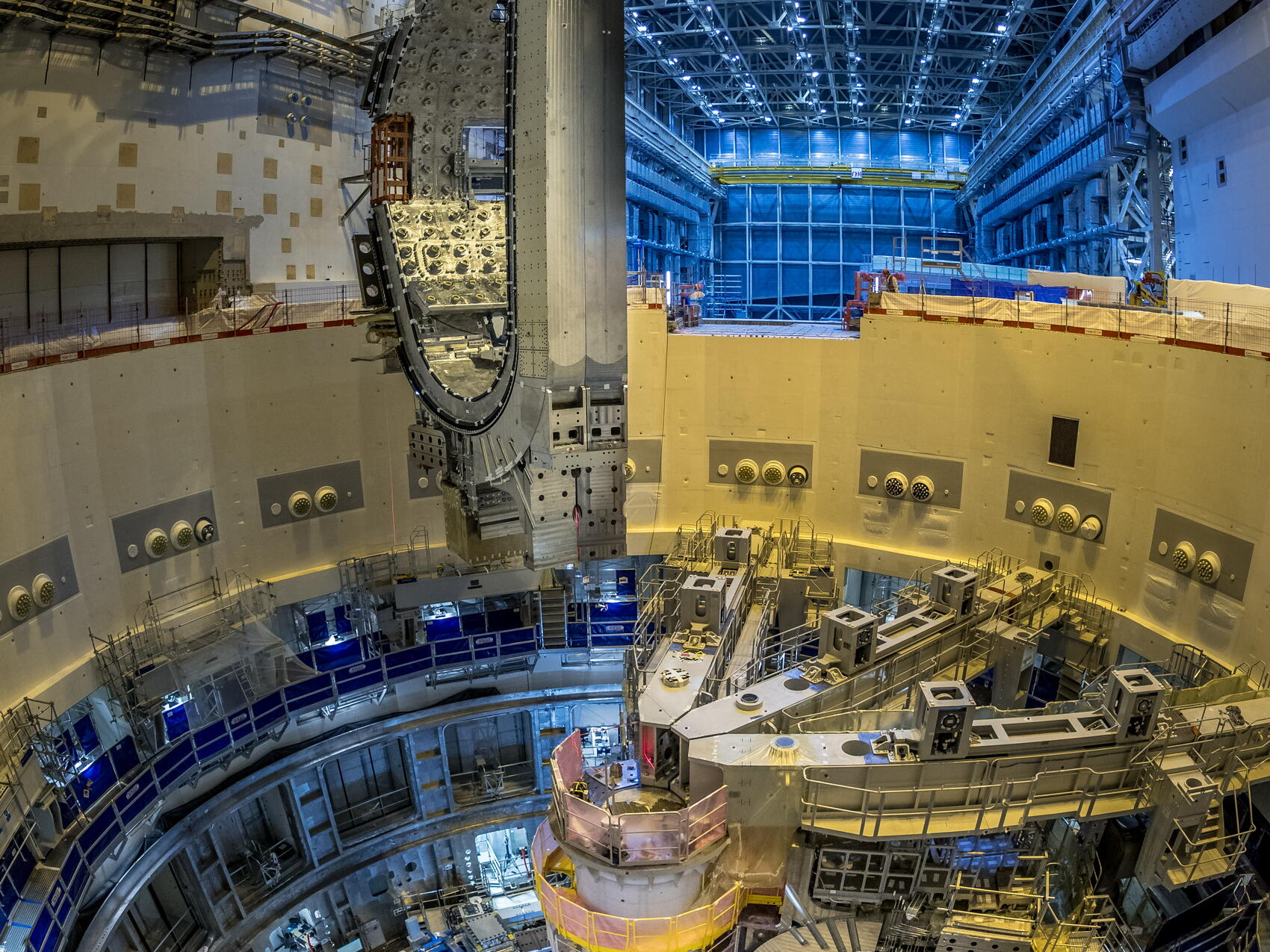

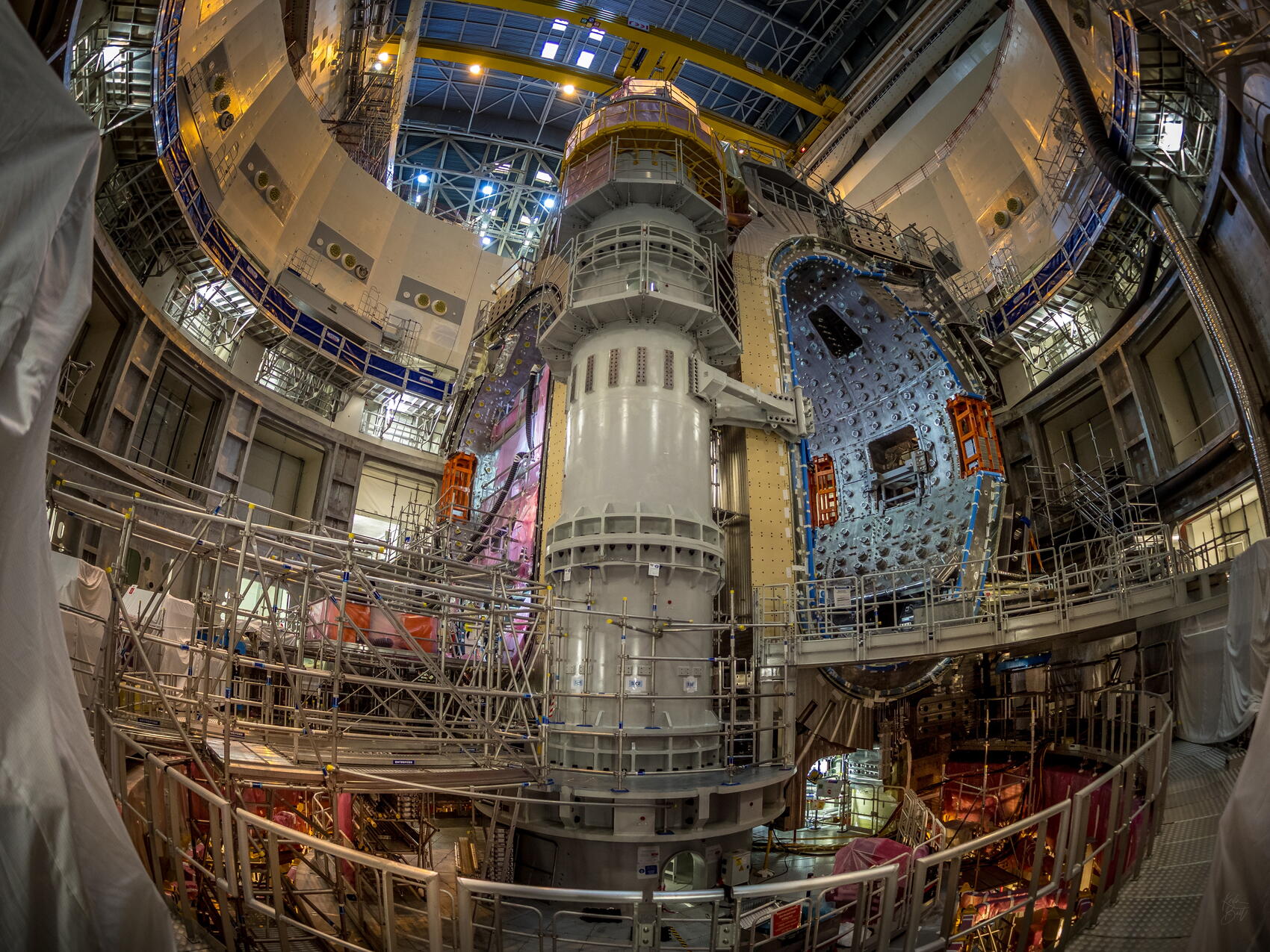

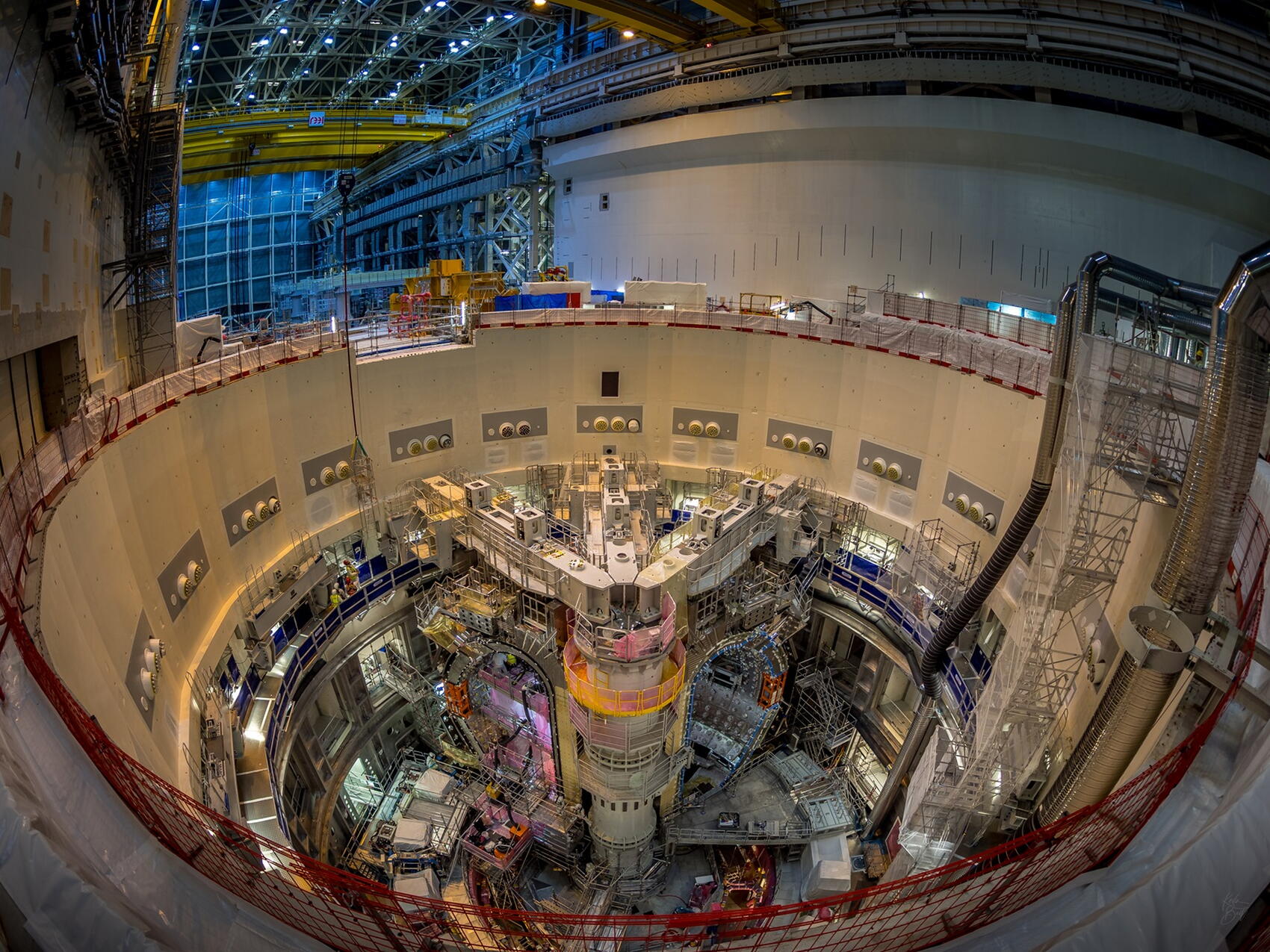

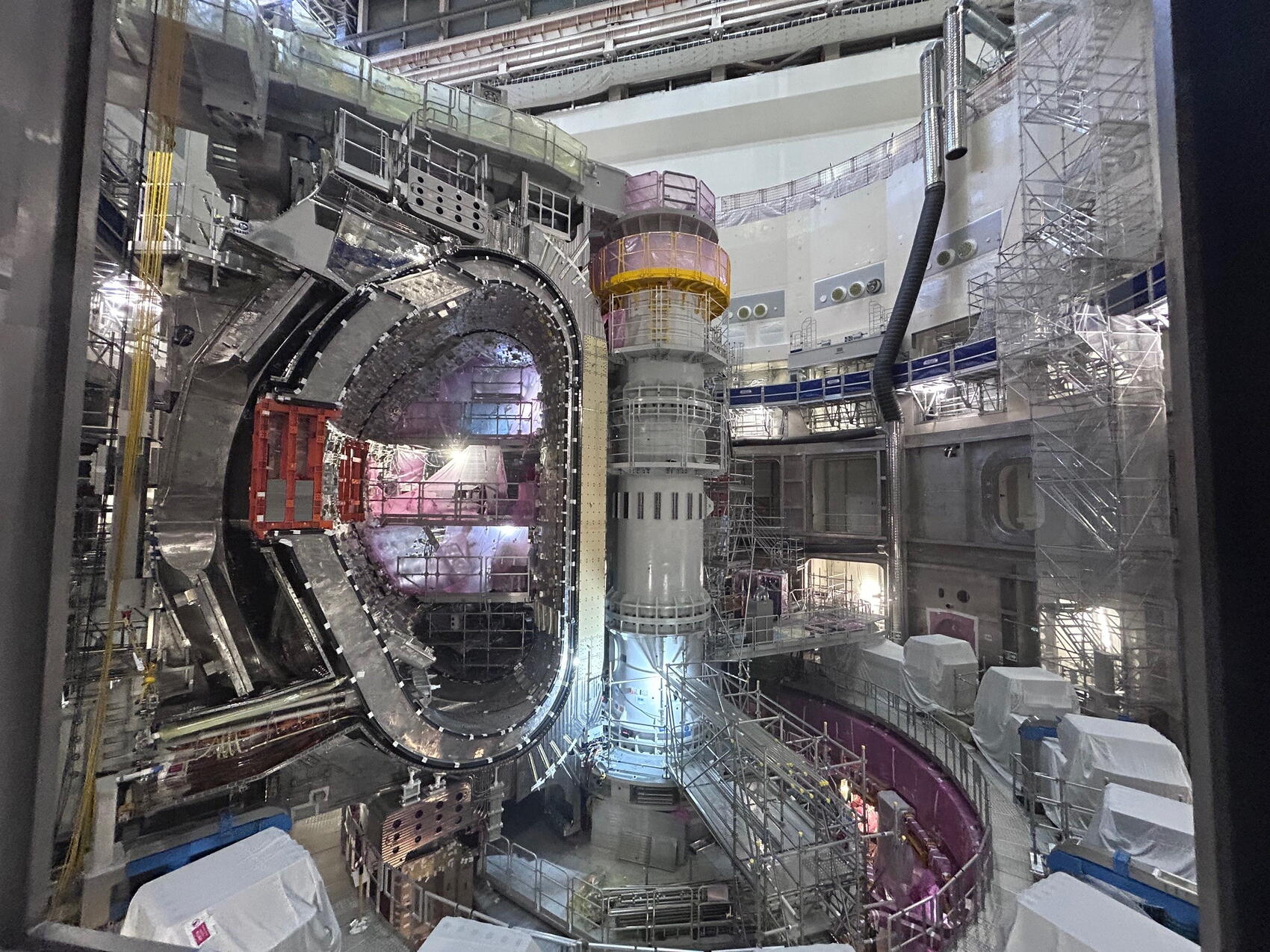

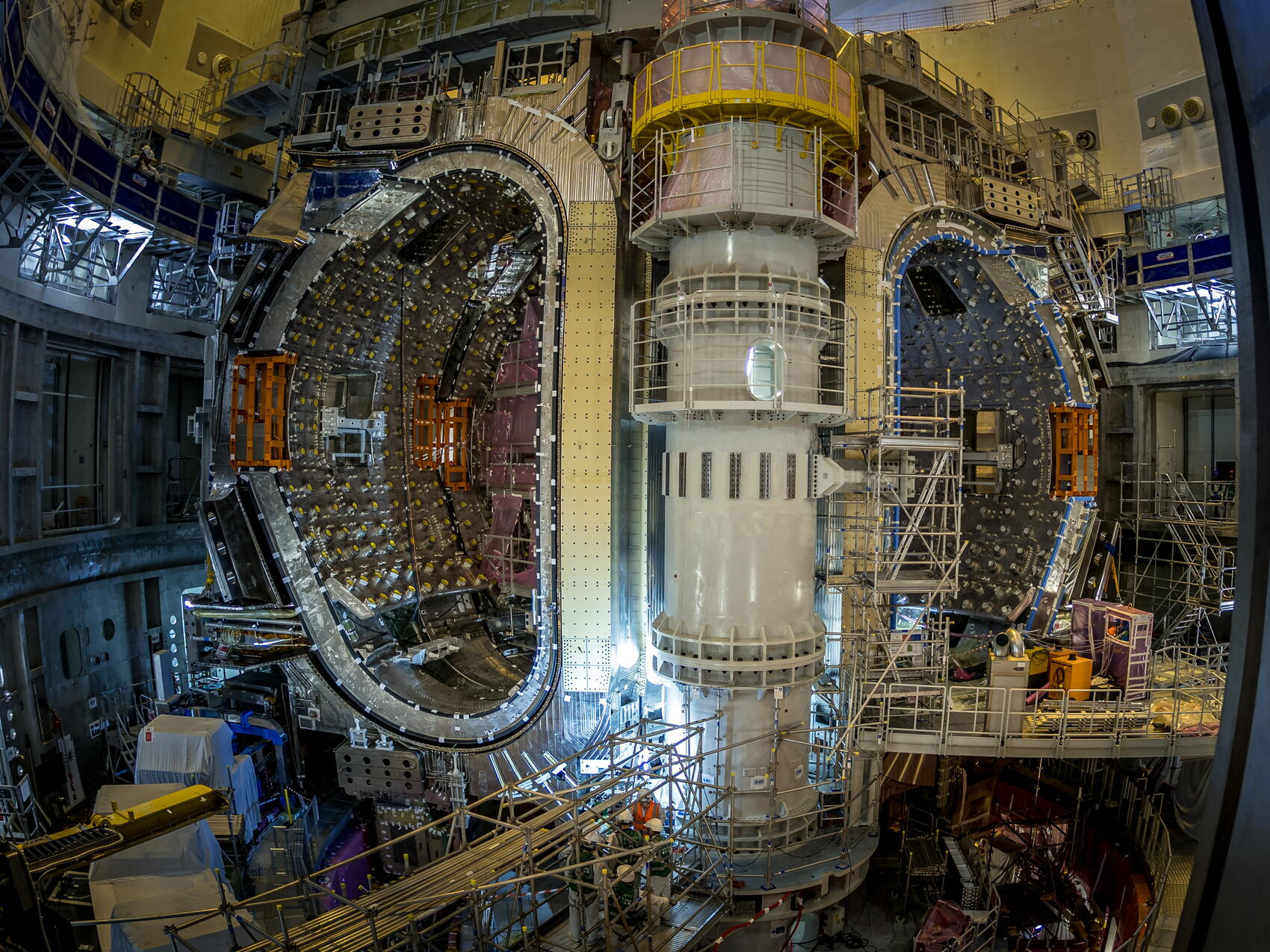

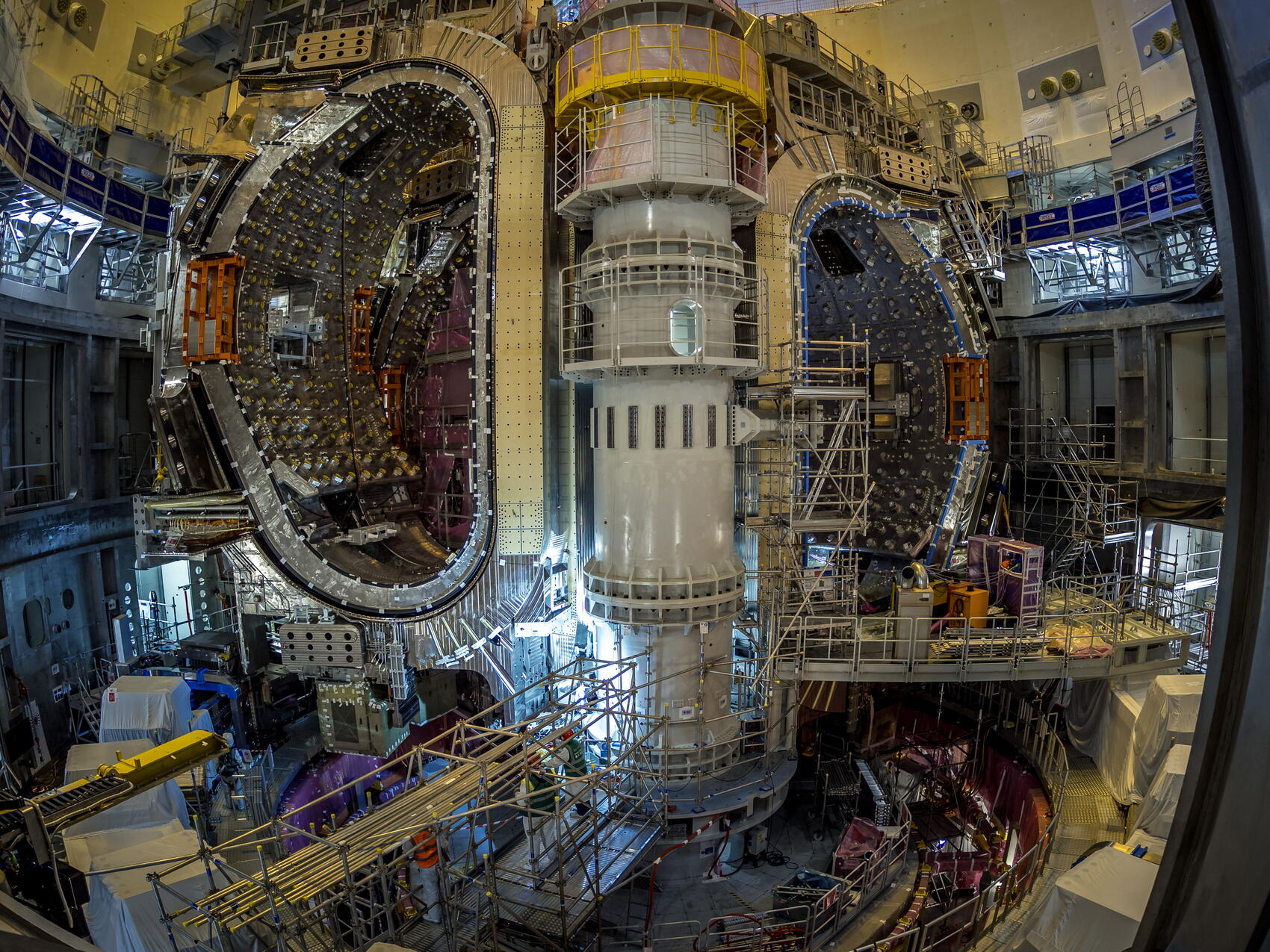

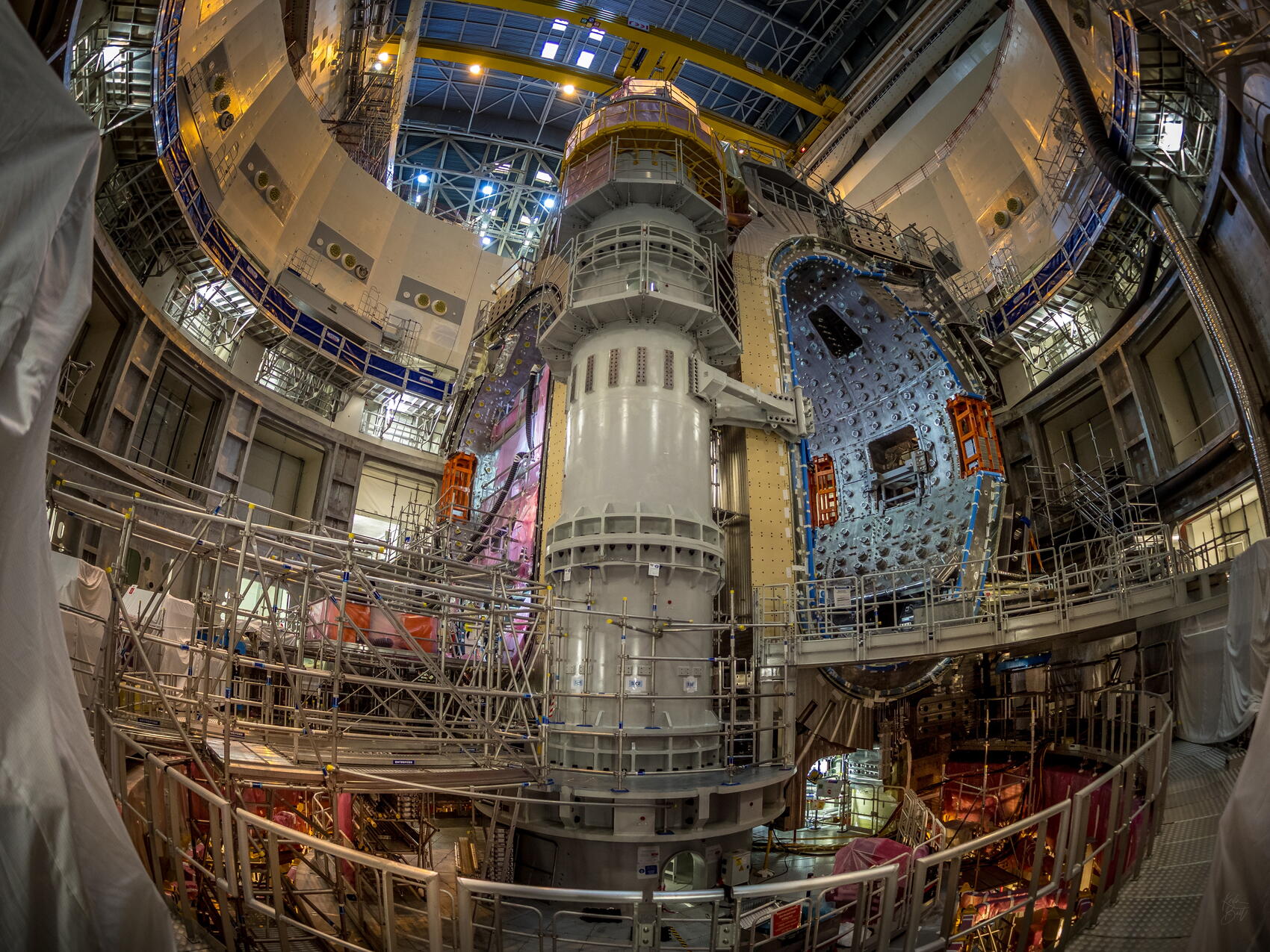

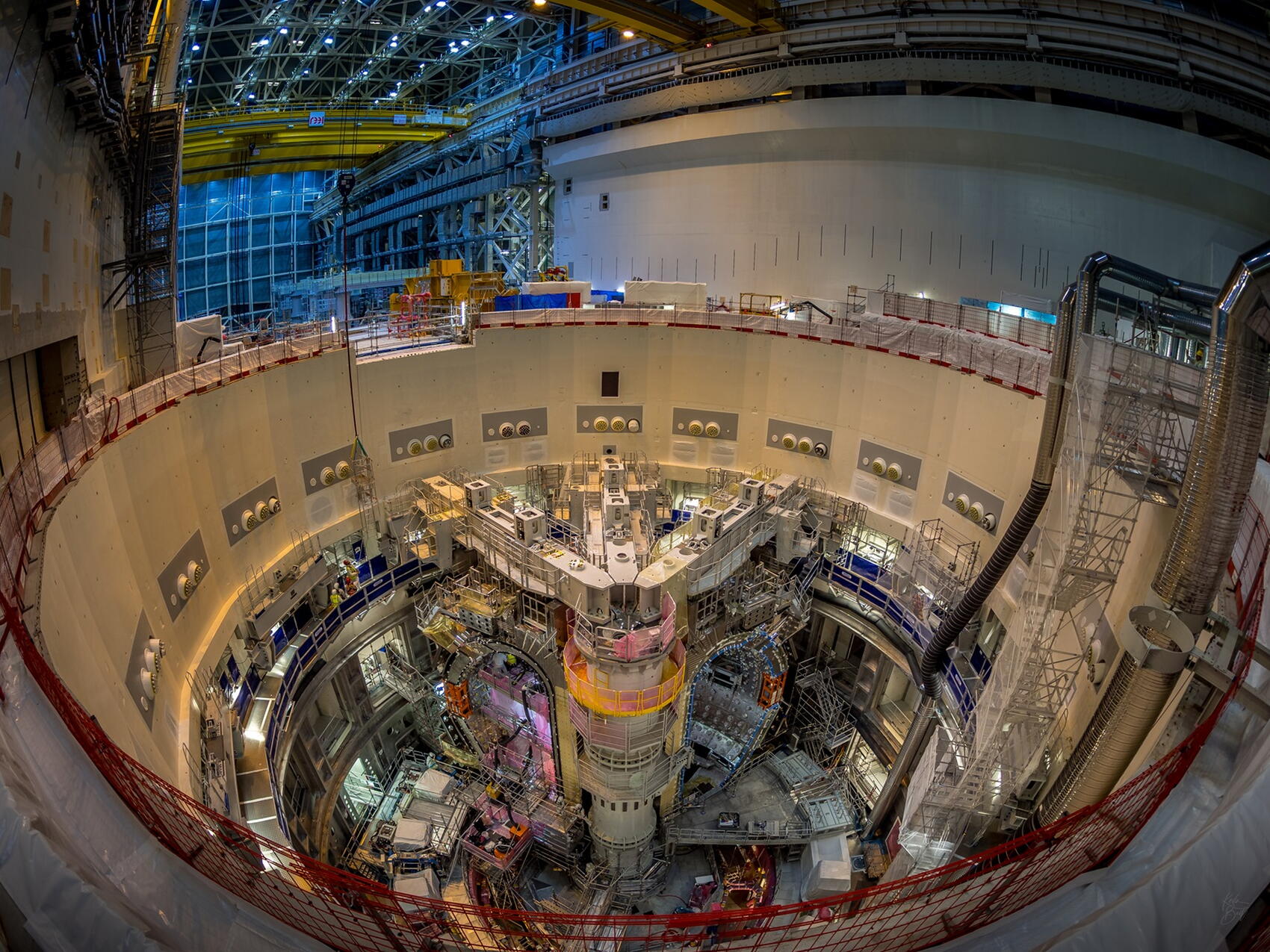

View from a port cell

2026-02-06 - For visitors to the Tokamak Building, this is the view they have of the ITER tokamak in construction. Four of nine vacuum vessel sectors are in place and a fifth is expected in May.

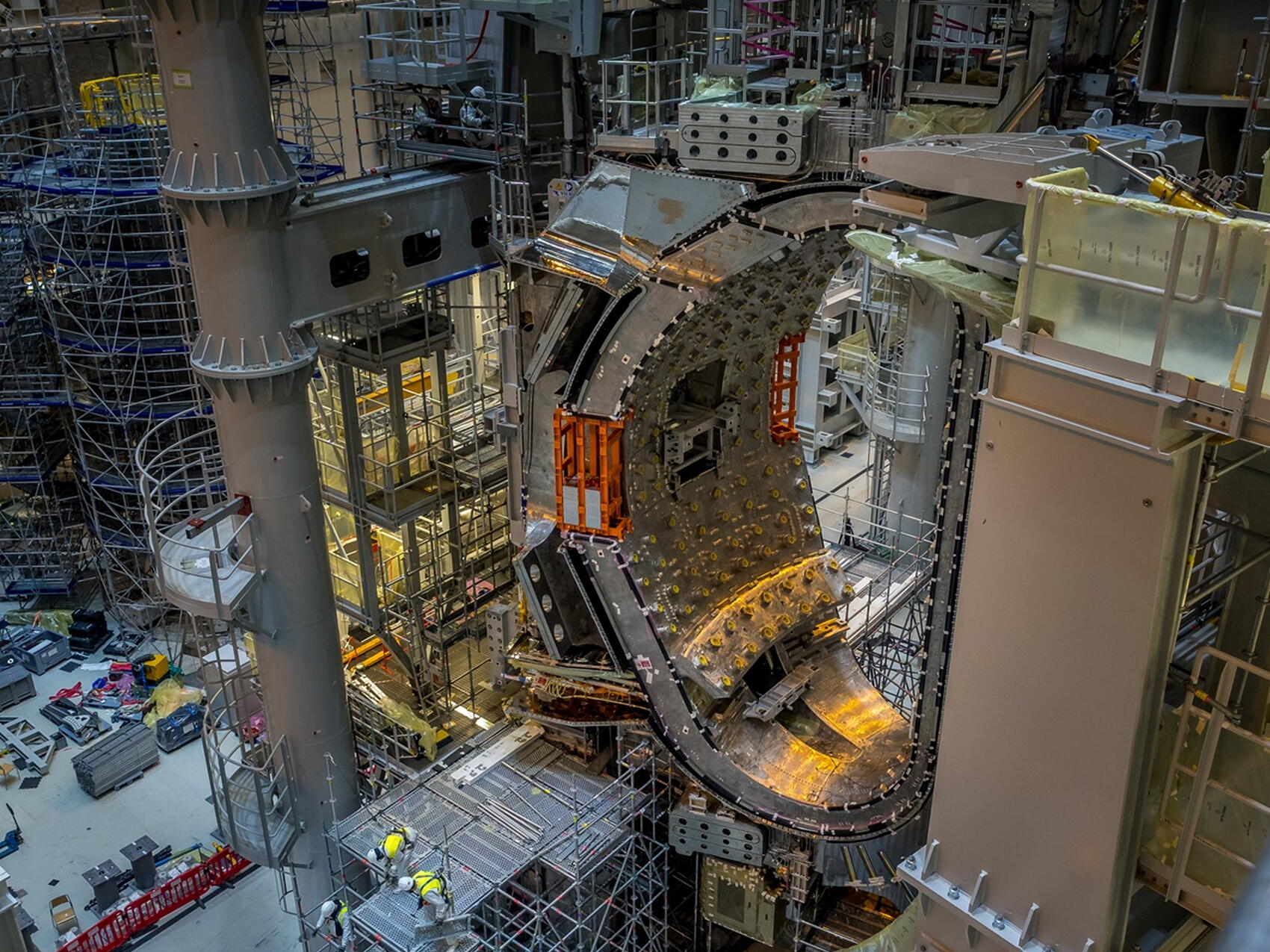

New sector upended

2026-02-06 - Another 40° sector of the ITER plasma chamber is in the process of being upended to vertical. A free sector sub-assembly tool awaits...

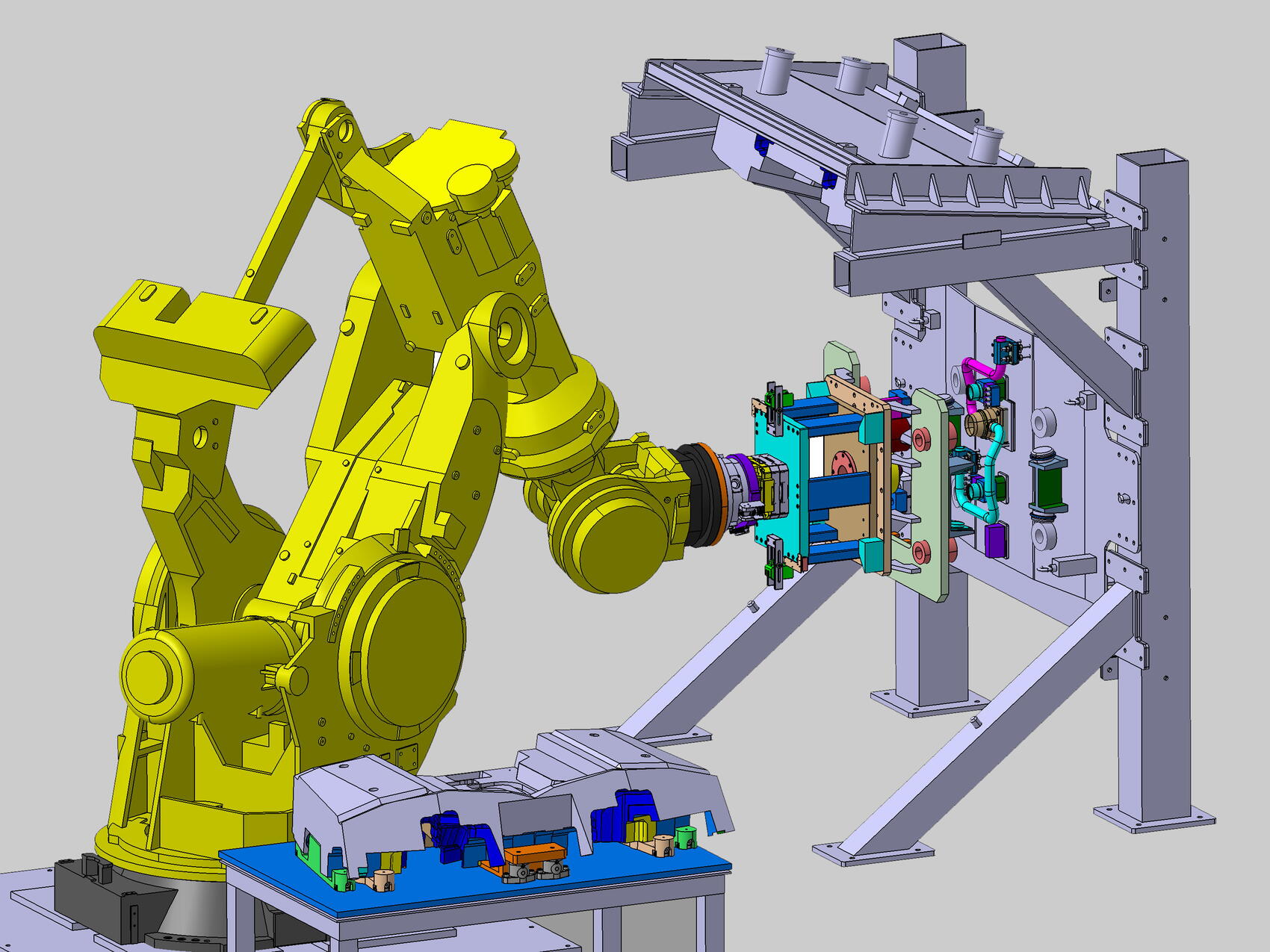

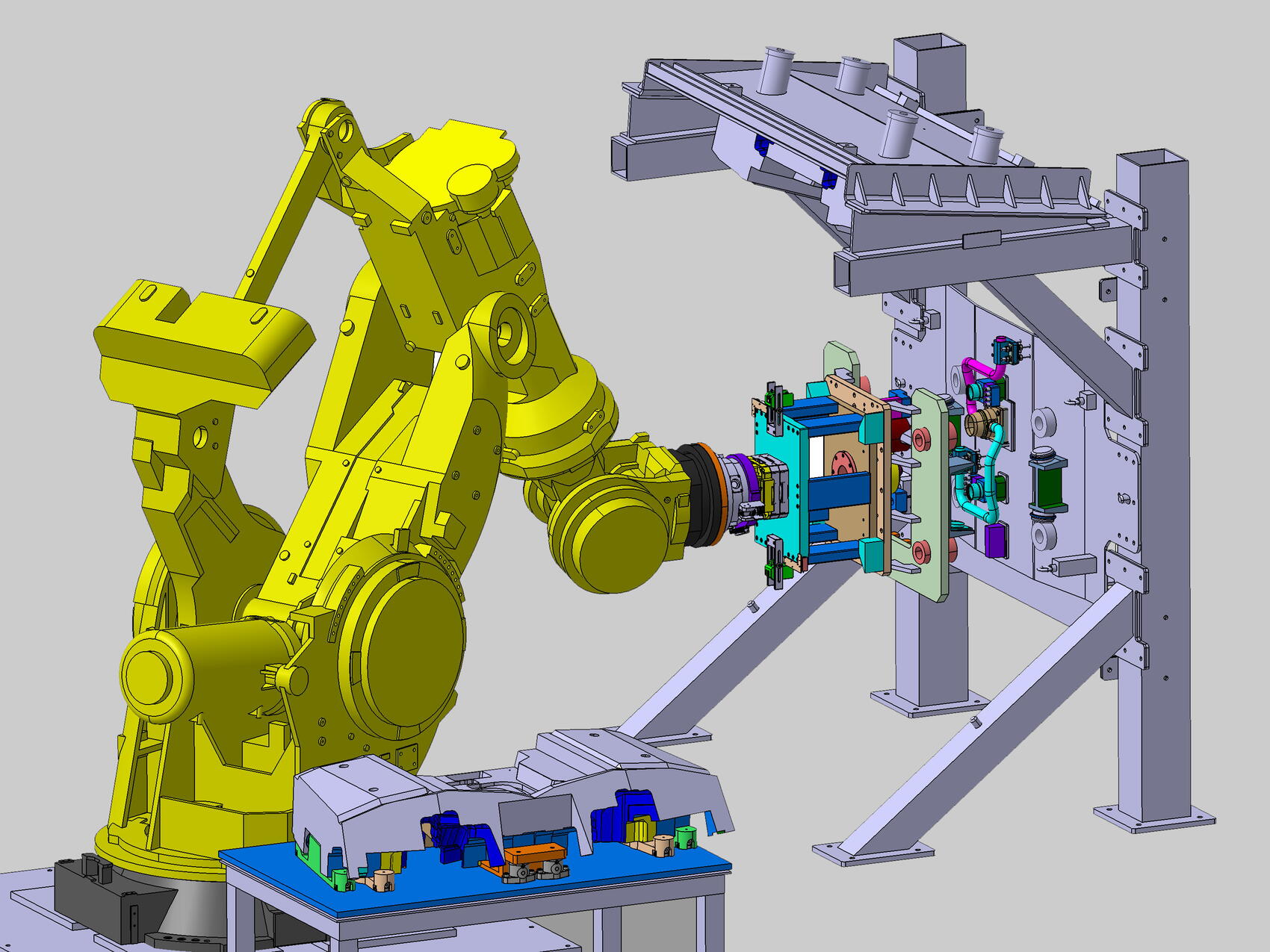

A robot called "Godzilla"

2026-02-02 - Standing 4 metres tall, with an arm that extends up to 5 metres, Godzilla is a platform for the developing and testing the tools and technologies that will be used by robots installing components inside of the completed vacuum vessel.

Calibrating Godzilla

2026-02-02 - In the basement of the Tokamak Assembly Preparation Building, operators are busy calibrating the Godzilla robot. Two partial "force and torque" prototypes on the tabletops in the foreground.

How Godzilla will work

2026-02-02 - Beginning in March, Godzilla will test the tools under development on mockups and interfaces that are representative of the in-vessel environment.

Just landed

2026-01-29 - The latest vacuum vessel sector module in the pit, #8, will soon be equipped with staging like the others.

Sector module #8 joins the gang

2026-01-29 - Vacuum vessel sector module #8 is the fourth module to be installed in ITER's machine assembly pit. It joins #7, #6, and #5, which were installed in 2025.

Next sector in line

2026-01-29 - Vacuum vessel sector #1 has been moved into the Assembly Hall to be upended and transferred to sub-assembly tooling. It will occupy the tool that was vacated two days ago by a sector module that was installed in the tokamak pit.

Through a port cell

2026-01-29 - Four sector modules are side by side in the tokamak pit. The latest arrival, sector module #8 (still attached to rigging, left), has not quite settled on its supports.

The pride shows

2026-01-28 - Nicolas Sapet, Sector Modules Assembly Project Leader, has three stickers on his hard hat showing his involvement in the three major vacuum vessel lift operations that took place in 2025. He's about to add a fourth...

Component ballet

2026-01-28 - This night team is receiving a handover briefing from the day team. While they discuss the transfer underway of sector module #8, another module is taking shape in the background—#4, the next to be installed.

Different hats, one team

2026-01-28 - An average of 150 people are involved in a major ITER lift. This crew posing in front of the module before it descends into the pit is emblematic of the different teams that are essential to each operation's success—the riggers, the lifting crew and engineers from machine assembly contractor CNPE/Framatome, ITER supervisors and assembly experts; construction management-as-agent technicians and engineers; metrologists, and crane technical support.

All go?

2026-01-28 - At 9:00 p.m. on the night of the lift, Fabien Noel (Facility Management Officer) and Jens Reich (Machine Assembly Program Manager) are focused on the data coming in from the different teams. Will it be an "all-go"?

Lowering operation ahead

2026-01-28 - At 6:00 p.m. on 28 January, sector module #8 has already passed over the wall that separates the Assembly Hall from the tokamak pit. The night team, meeting now for a debrief session, will be responsible for lowering the component into the pit.

Fourth module positioned above the pit

2026-01-28 - Late at night, on Wednesday, 28 January, sector module #8 is positioned above its landing position, but adjustments must still be made. A special lift attachment between the overhead cranes and the load is equipped with a balance control system that can perform horizontal-plane load adjustments along the X and Y axes. Another allows it to pivot.

Side by side, for the moment

2026-01-28 - The fourth sector module of the ITER vacuum vessel, #8, will take its place next to sector modules #5, #6 and #7 in the pit. The next module to be inserted, however, will be placed across from these four.

Major lift underway at ITER

2026-01-28 - Vacuum vessel sector module #8 is making its way into the tokamak pit. The major lift operation has begun and will continue through the night.

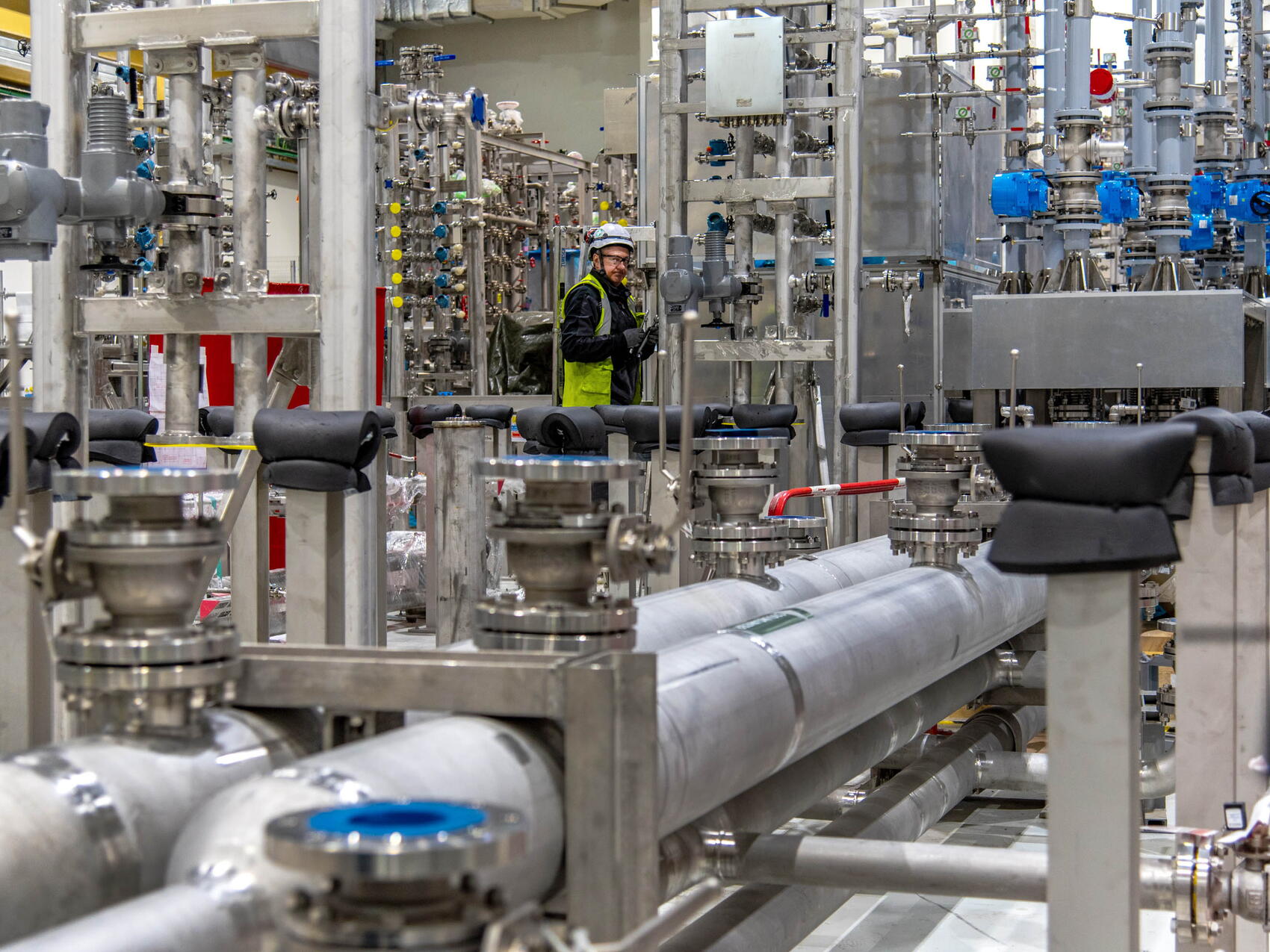

Gyrotron forest

2026-01-16 - Two gyrotrons are now installed in the forest of dull grey piping, shining steel manifolds and brightly coloured cables that covers the third level of the Radiofrequency Building, home of the electron cyclotron resonance heating (ECRH) system.

Second gyrotron installed

2026-01-16 - A second gyrotron, also delivered by Japan, was installed last week. When all work is completed, it will look exactly like its sibling (far left) that is now in commissioning.

Nearly ready for transfer

2026-01-15 - Sector module #8 is nearly ready to be transported out of tooling and into the tokamak pit. Visible in this photo are the central vacuum vessel sector, its wafer-thin thermal shield, and the toroidal field coil superstructure (triple dots).

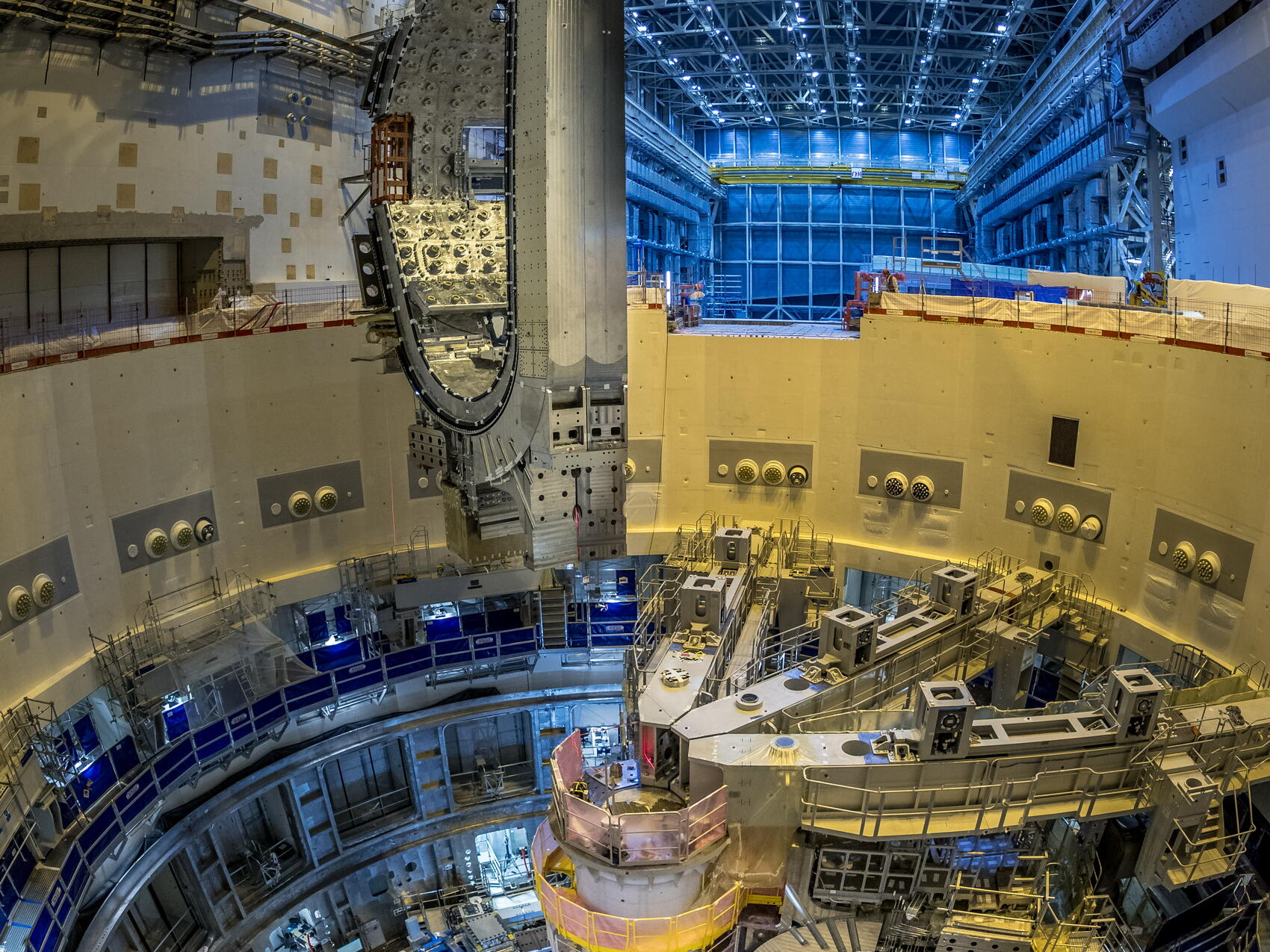

From above

2026-01-15 - Thanks to temporary staging platforms, teams can access every level of this vacuum vessel sector module in the tokamak pit.

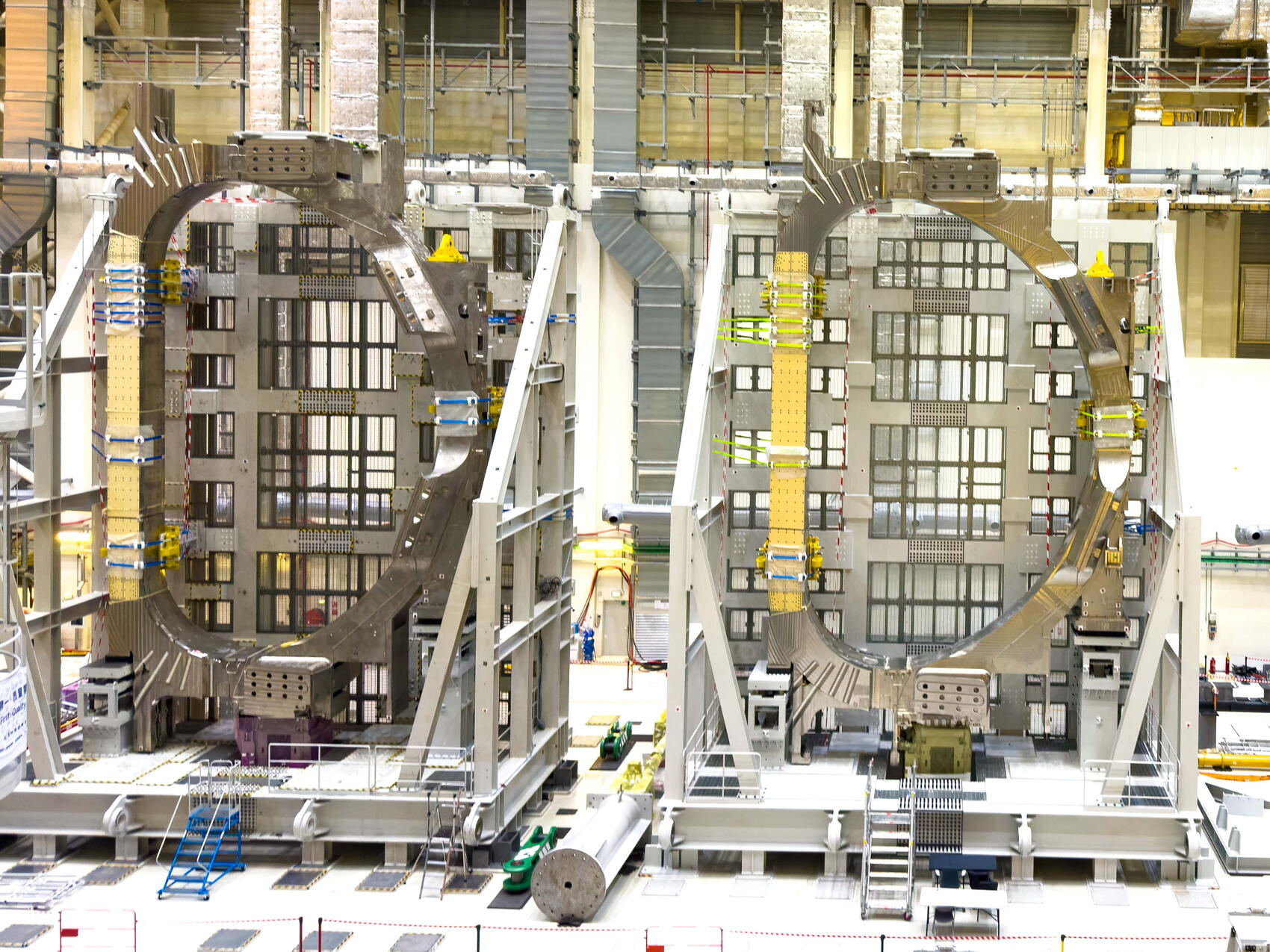

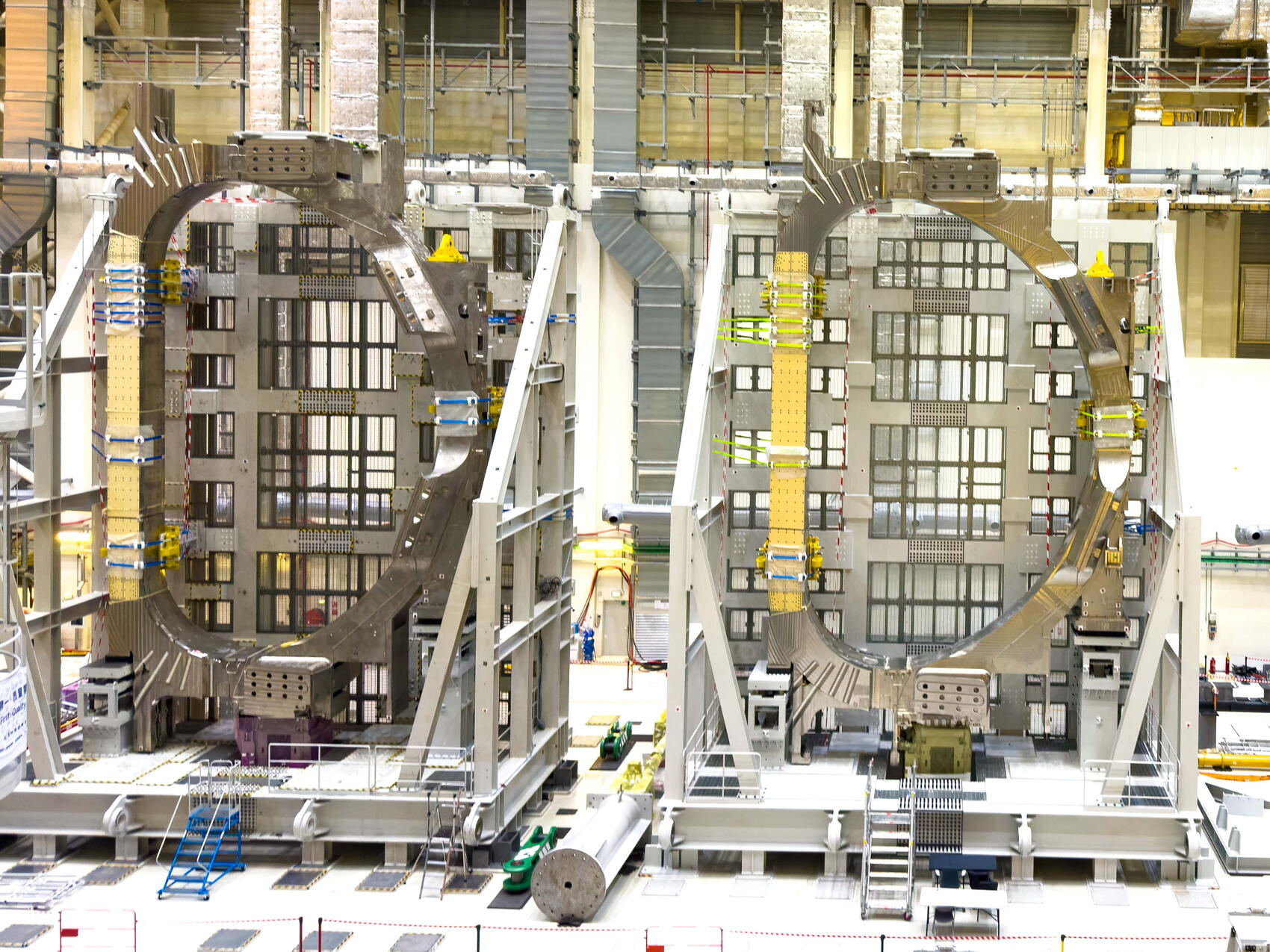

Specialized "cradles"

2026-01-15 - For every job, a bespoke tool. In this photo, the upending tool on the left is lifting a D-shaped toroidal field coil into a vertical position, mirroring the tool on the right, which has already completed the operation for the second coil in the pair.

Sector #1: all repairs completed

2026-01-15 - Activity on vacuum vessel sector #1 is nearing completion and the component is scheduled to be transferred to the Assembly Hall at the end of January 2026. It is next in line for transfer to the tall sub-assembly tools where "sectors" are associated with other components to become "sector modules."

A near-finalized sector module

2026-01-15 - Another view of the near-finalized sector module #8. It took less than five full months for sub-assembly activities to be completed.

Third of the way there

2026-01-15 - Three of nine sector modules have been installed in the ITER tokamak assembly pit. A fourth is expected later this month.

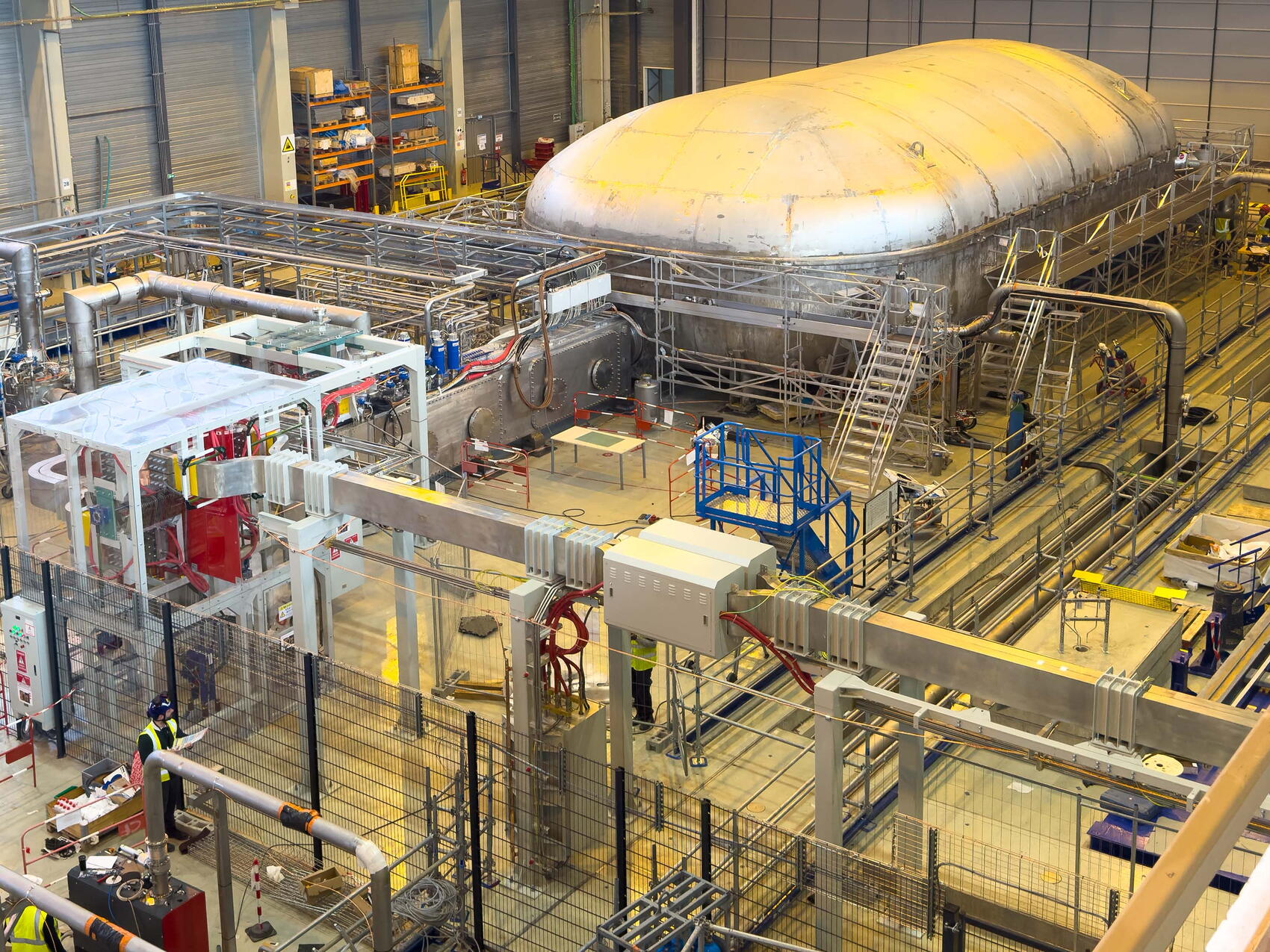

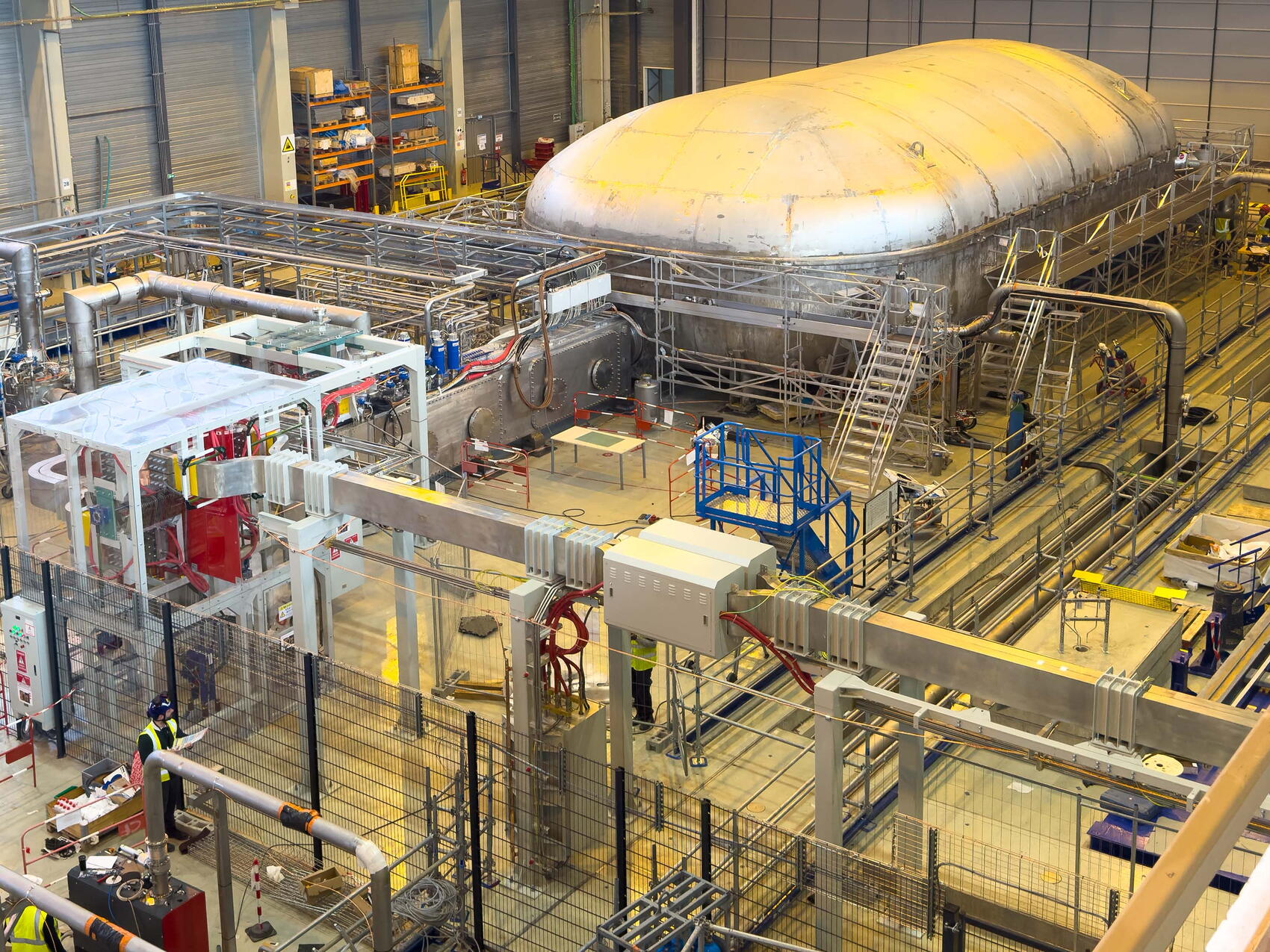

A closed cryo chamber

2026-01-15 - The first toroidal field coil is in the magnet test facility and high-voltage commissioning of the power converter is underway to be sure the systems are ready to test the magnet at 4 K (minus 269 degrees Celsius).

Side by side

2026-01-15 - Toroidal field coil #2 and toroidal field coil #3 have been raised to vertical in adjacent upending tools and are awaiting transfer to one of the sector sub-assembly tools to be paired with vacuum vessel sector #4.

Filling up

2026-01-15 - The "production line" for sector modules is accelerating at ITER. Three completed sector modules were installed in the pit in 2025 and another is going in at the end of January 2026.

Last activities on sector module #8

2026-01-09 - In the Assembly Hall, vacuum vessel sector module #8 is now in the final stages of assembly. (In this photo, a last piece—a small segment of thermal shield—is being transported to the tall tool, left.) Sector module #8 is scheduled to be lifted into the tokamak pit at the end of the month.