"Manufacturing underway" Gallery

Dual-hinged gravity support

2026-02-16 - Nine gravity supports like this one, supplied by Korea, will support the vacuum vessel sectors from below. Their dual-hinged design allows for a slight expansion of the vacuum vessel in the radial direction.

Europe has completed a third sector

2026-02-02 - Vacuum vessel sector #9, shown here at the Westinghouse Mangiarotti factory in Monfalcone, Italy, is ready for transport to ITER. Sector #9 will be the third sector delivered by the European Domestic Agency. ©Westinghouse

Europe is developing a "vehicle" for a specialized task

2026-01-28 - This semi-automated platform fabricated in Europe is designed to carry ITER port plugs from the Assembly Hall to their positions in the upper and equatorial ports surrounding the vacuum vessel during first-phase assembly. Recent tests confirmed it can negotiate ITER-like gallery corridors while carrying an 80-tonne dummy load on its back. ©Solving

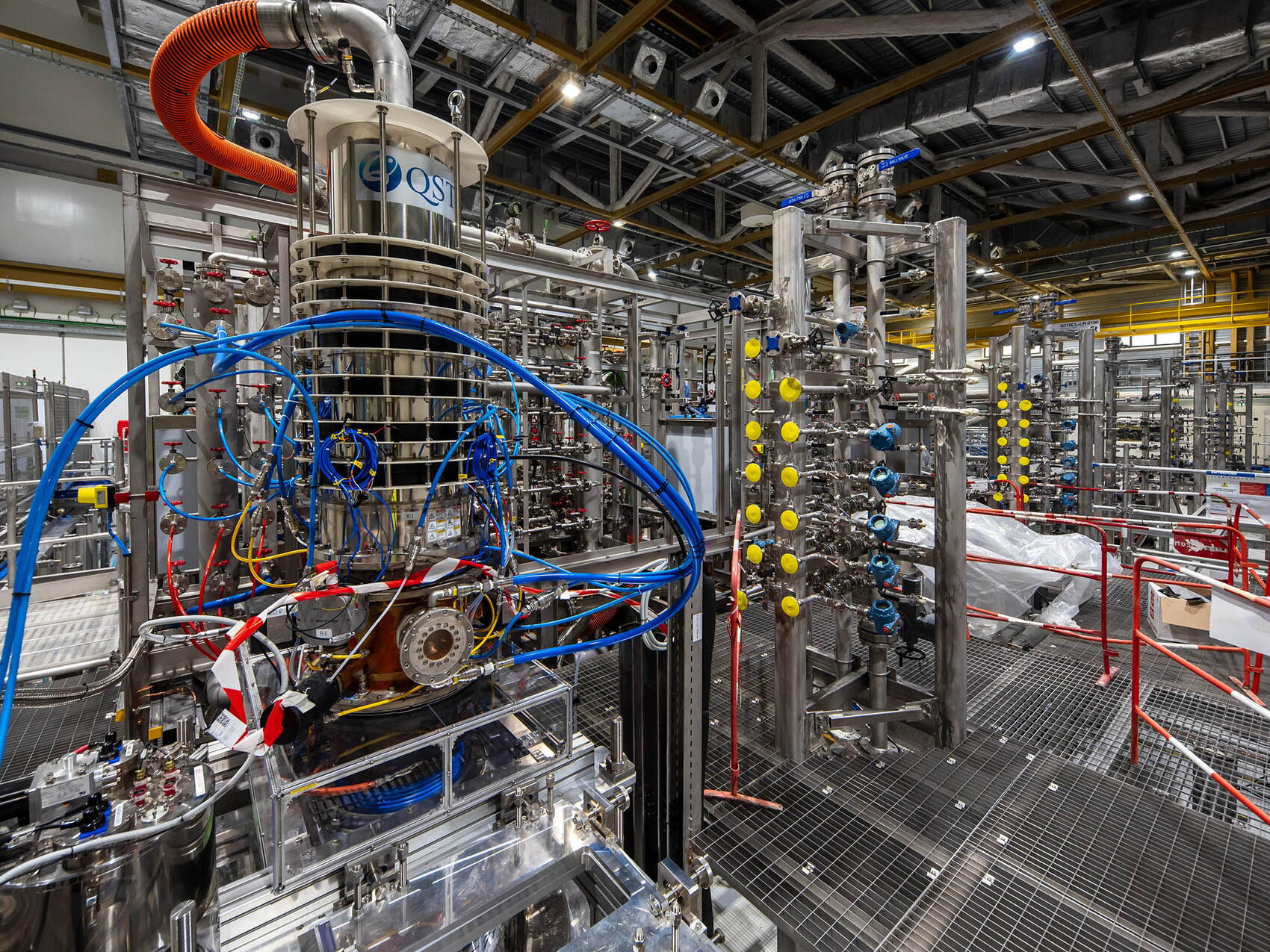

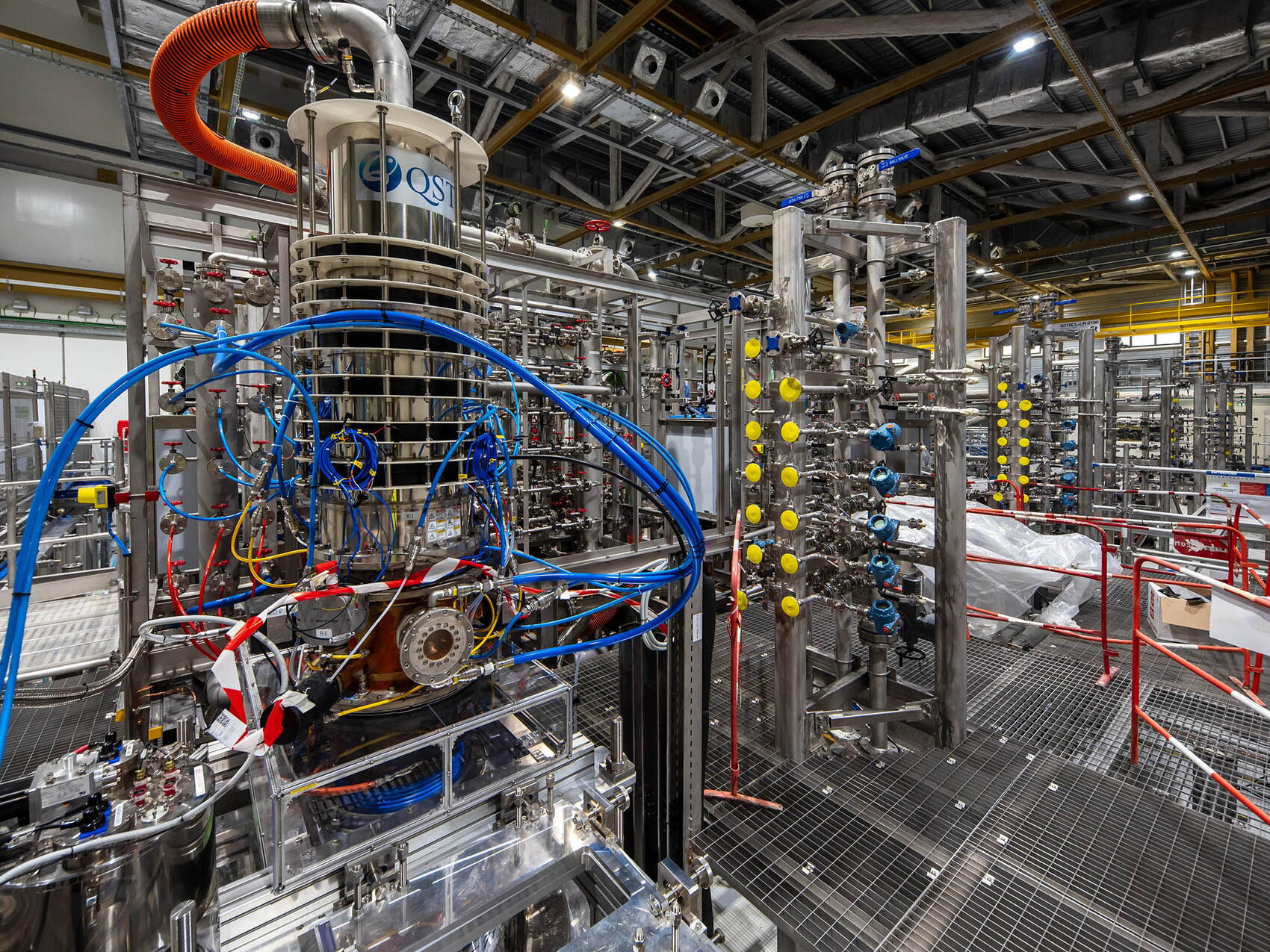

High-tech waves

2026-01-16 - A gyrotron is essentially an energy-delivery device. Once generated in the magnetic tube, high-frequency waves travel the length of a wave guide into an antenna that directs the beam into the plasma. The effect of the high-frequency wave on the electrons in the plasma is to accelerate their motion—another way of saying that electrons are "heated" by the high frequency beam. Two gyrotrons delivered by the Japanese Domestic Agency have already been installed at ITER.

European industry tackles first wall panels

2026-01-09 - Suppliers Alsymex and Fusion Business Leadership (Leading/Empresarios Agrupados) have been entrusted by the European Domestic Agency with the production of 27 first-wall panels each. After years of development, series production lines are up and running and teams are focusing on shaping the structure of the panels, made of a stainless steel-copper alloy. ©FBL-F4E