Worksite progress

Once upon a crane

9 Apr 2018

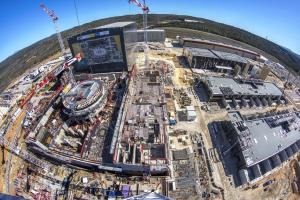

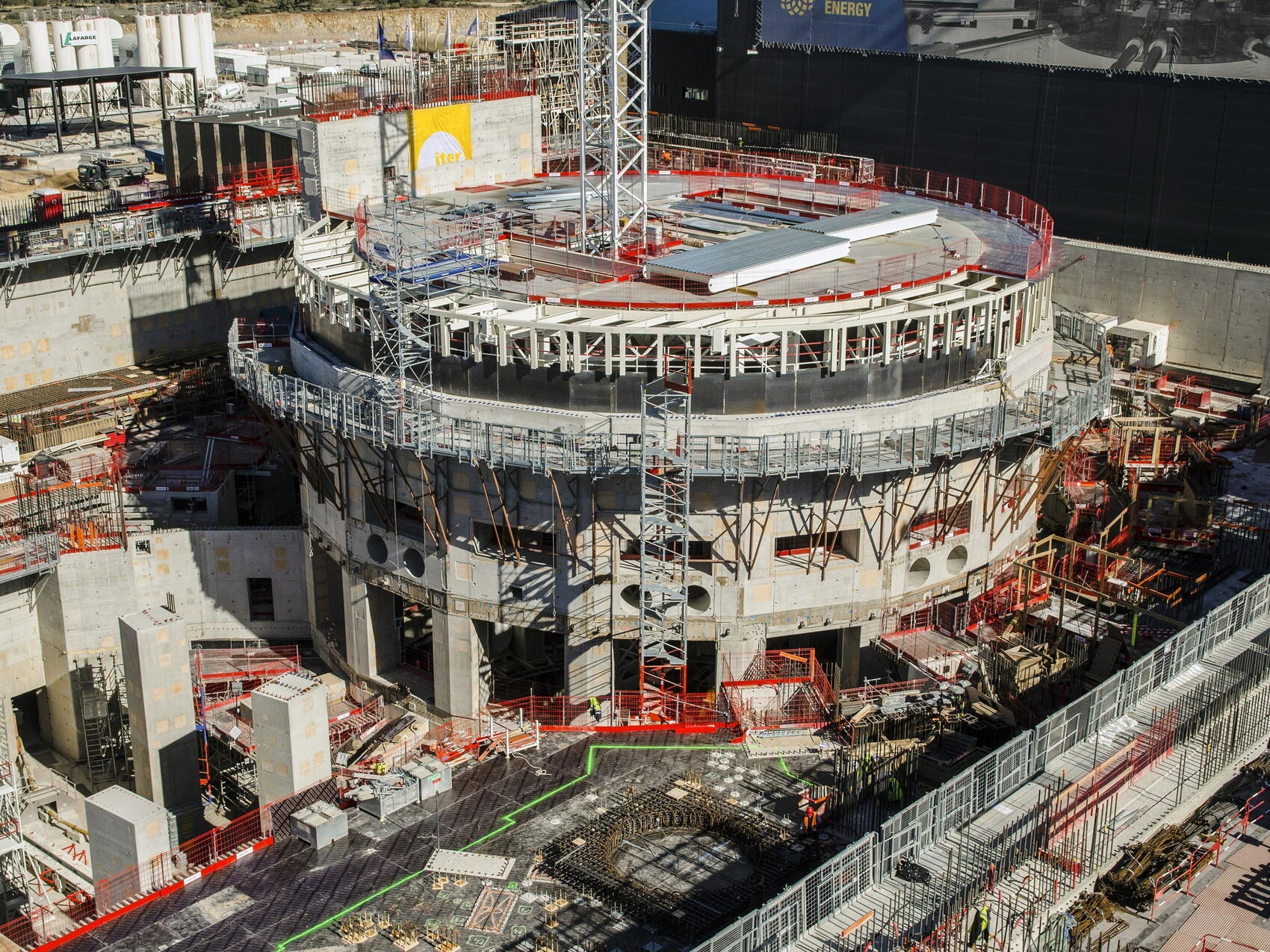

Of all the features that have changed the most since the last bird's eye view of the ITER site in January, the bioshield is the most striking. For two years, the structure had remained open to the sky, looking more and more like Rome's Colosseum as it grew, with its circular shape and row upon row of large openings.

The first machine component—a magnet feeder—will enter the assembly arena through openings in the bioshield lid. But for the installation of major components like the 1,250-tonne cryostat base or the vacuum vessel sectors, the building will be covered over and the lid removed. The major components will be delivered to the pit area by overhead crane.

That vision is now gone. The "lid" that had been installed at mid-height since September was recently lifted to the top of the structure, closing off the massive steel-and-concrete cylinder. We are no longer looking at the Roman Colosseum, but at something more reminiscent of Hadrian's mausoleum...

Other changes, observed from the highest crane on the site, are less spectacular but no less significant in terms of worksite progress. Please see the details in the gallery below.