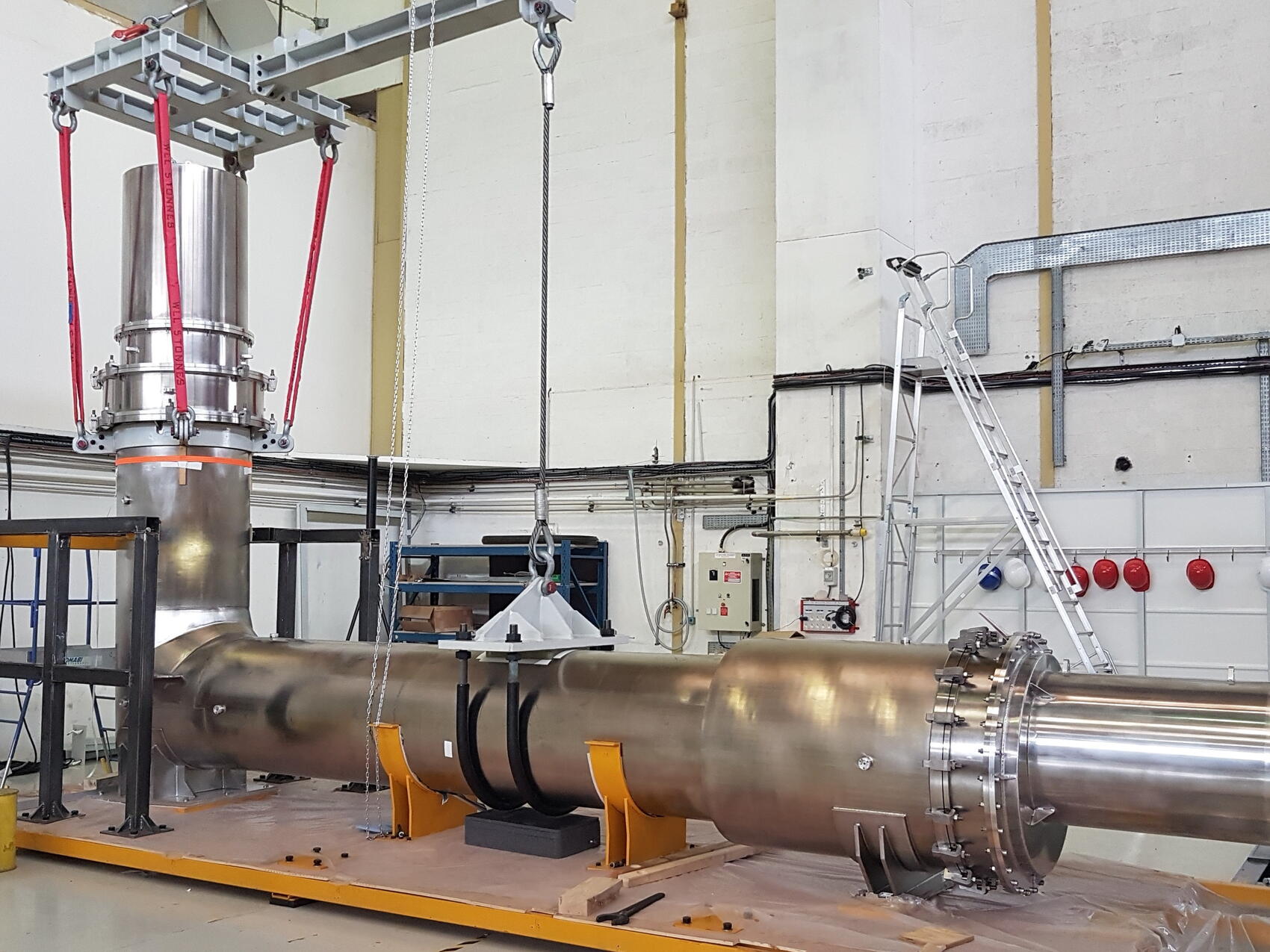

An activity that began with the transfer of the component to the vicinity of the Tokamak Complex—and that was pursued as the 10-metre, 6.6-tonne component was introduced into the pit through an opening in the bioshield roof—has now been concluded through the final positioning of the feeder segment in the building.

In the final lift sequence, the elbow-shaped component was raised by the monorail crane at the bottom of the tokamak pit, rotated above the

cryostat crown, and lowered into a slim opening that had been left in the concrete circle in anticipation of this very installation sequence. Positioned on a temporary support tool supplied by the Korean Domestic Agency, technicians used cables to draw the horizontal segment of the feedthrough into the bioshield opening, while the vertical segment fell into place between the crown and the bioshield. (

See more detail in the photo gallery below.)

If magnet feeders are the essential lifelines of the ITER magnets—carrying electricity, cryogenic fluids and instrumentation cables—"feedthroughs" are the part of the feeder assemblies that cross through the bioshield and the cryostat. This first completed unit had been delivered

last year to the Magnet Infrastructure Facilities for ITER (

MIFI) where, as a first-of-a-kind component, it underwent high-voltage tests, leak tests and endoscopic

inspection.

Ultimately, the feedthrough will be joined by two other components—an in-cryostat feeder (nearest the vacuum vessel) and a coil termination box (outside the bioshield)—to connect to poloidal field coil #4, one of the two largest of the machine's six poloidal field coils (24 metres in diameter).

"A large number of actors played a critical role in the installation operation that concluded last week," notes Bruno Levesy, Group Leader of the In-Cryostat Assembly Section, with satisfaction, "The Domestic Agencies of China (fabrication) and Korea (tooling), the ITER Organization logistics provider DAHER (transport), European Domestic Agency building contractors, ITER's Construction Management-as-Agent contractor, and the French company CNIM (which won the early works contract in the tokamak pit) all participated." Giobatta Lanfranco (Construction Team) and Bruno were the most involved staff members of the ITER Organization. "It has been a good practice in coordination for the many activities to come."