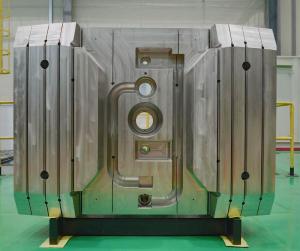

The first series production unit, SB06A—for row 6 (situated near the top of the vessel on the inboard wall of the chamber), type A—has now been completed in Korea, including factory acceptance tests and the production of all required documentation. For future series production units, it is expected that the manufacturing can be accelerated through the experience gained and strong production and quality management systems.

Rene Raffray, Blanket Integrated Product Team Leader, congratulated Korean colleagues on the achievement of this important milestone. "This is not only the first series production shield block to be completed in Korea but also the first major series component of the blanket system to be successfully manufactured and tested, and as such it is a major step forward. It also testifies to the strong progress in the procurement of the shield blocks and to the productive collaboration between the ITER Organization and the procuring Domestic Agencies."

The Director-General of ITER Korea, Kijung JUNG, took pride in the accomplishment, saying: "We are happy to be engaging in some of the most difficult challenges in terms of fusion technology, so that our industry will be ready for the commercialization of hydrogen fusion. After the recent successes on the ITER

vacuum vessel, we know we are strengthening the capabilities of our domestic industries through participation in ITER."

In parallel, procurement is also progressing well

in China, with all shield blocks in rows 09 and 10 in series production, as well as several for row 17. Final machining has been completed on one row 10 shield block and final factory acceptance tests are underway.