An elbow through the wall

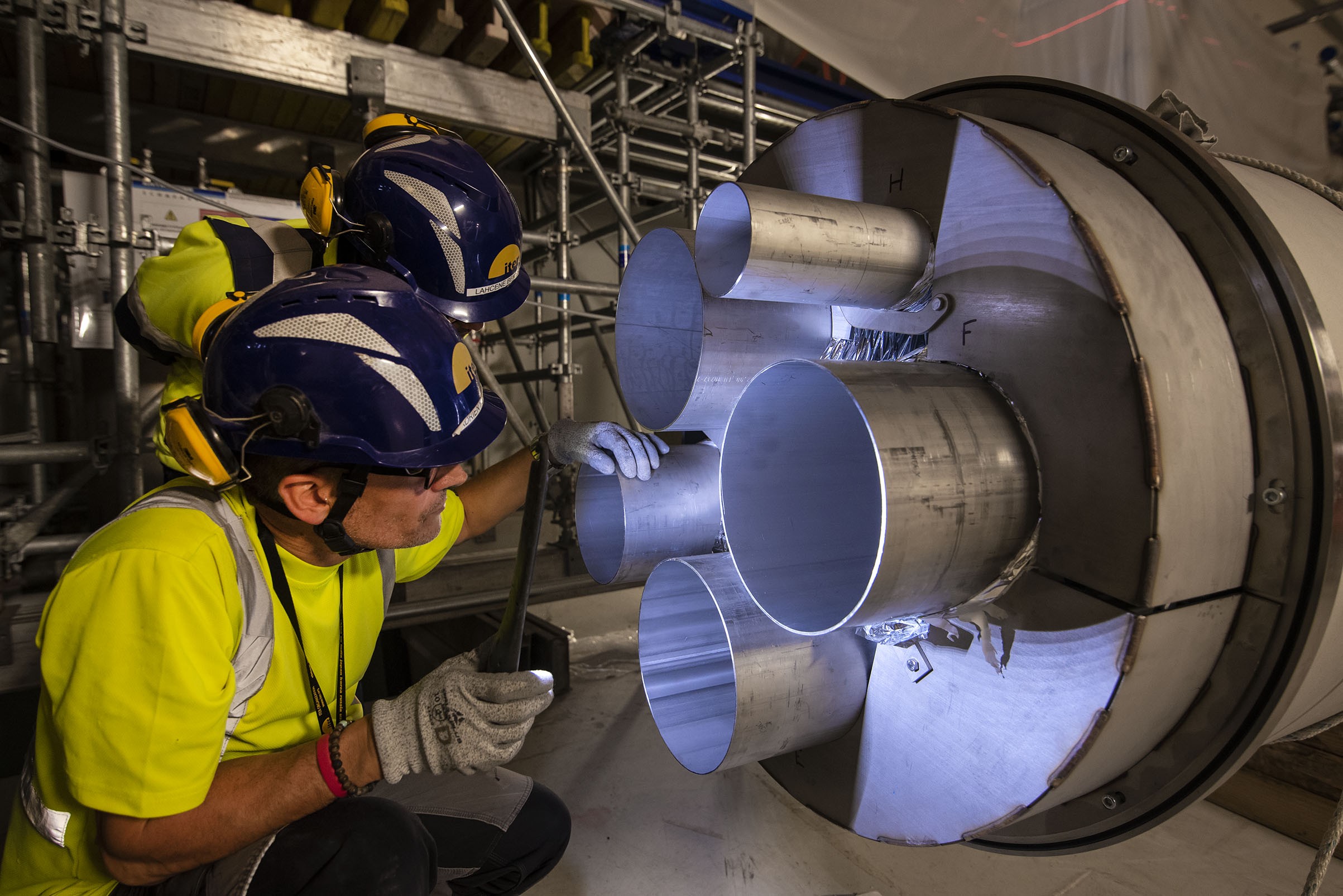

Cool is in high demand in the ITER tokamak. Magnets need it to achieve superconductivity, the thermal shield to limit heat exchanges with the outside environment, cryopumps to trap particles and achieve high vacuum, and HTS current leads to minimize heat loads to the cryogenic system. "Cool" originates in the ITER cryoplant, where helium is processed before reaching its different clients by way of a five-kilometre network of multi-process pipes called cryolines that are provided by ITER India.

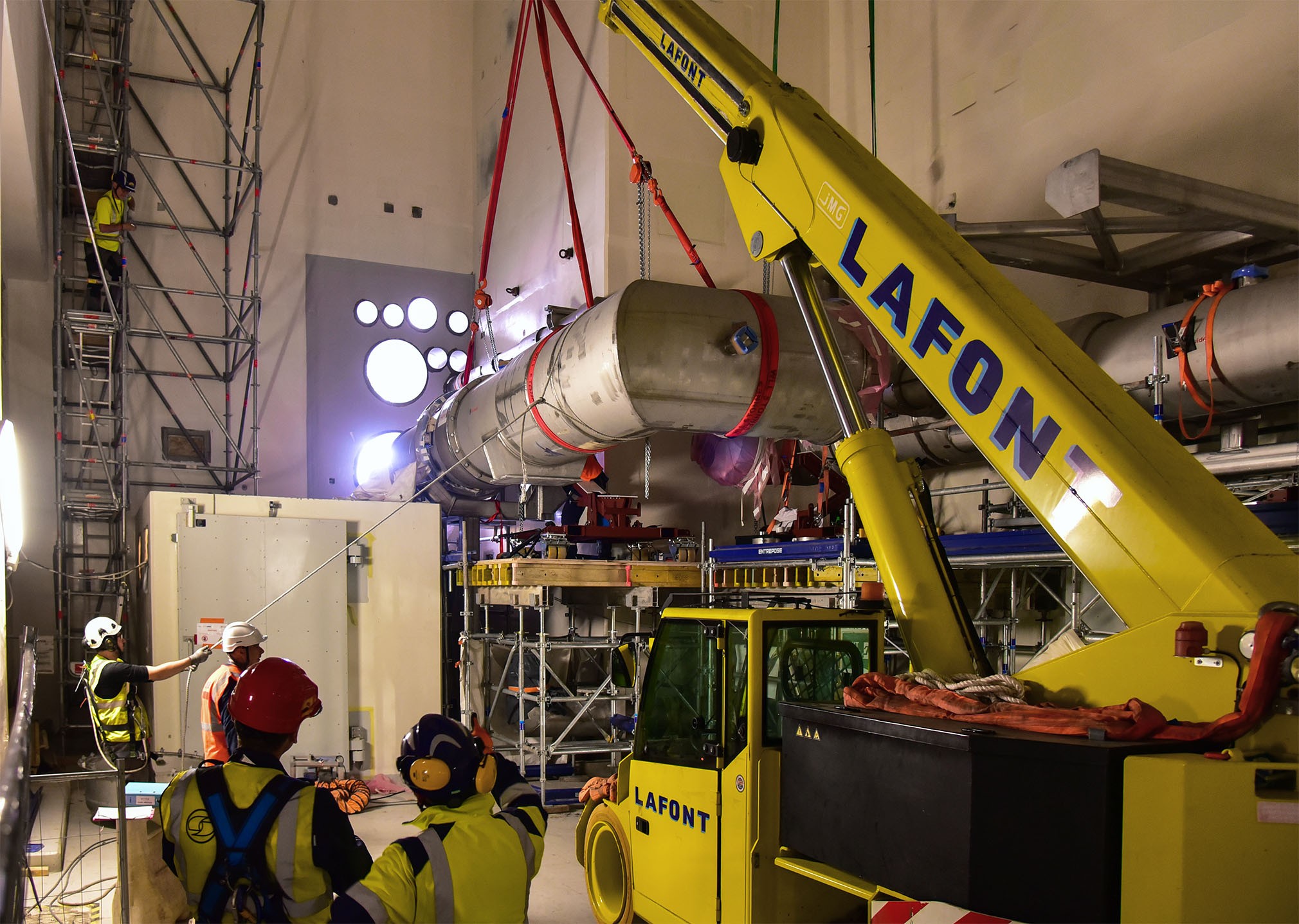

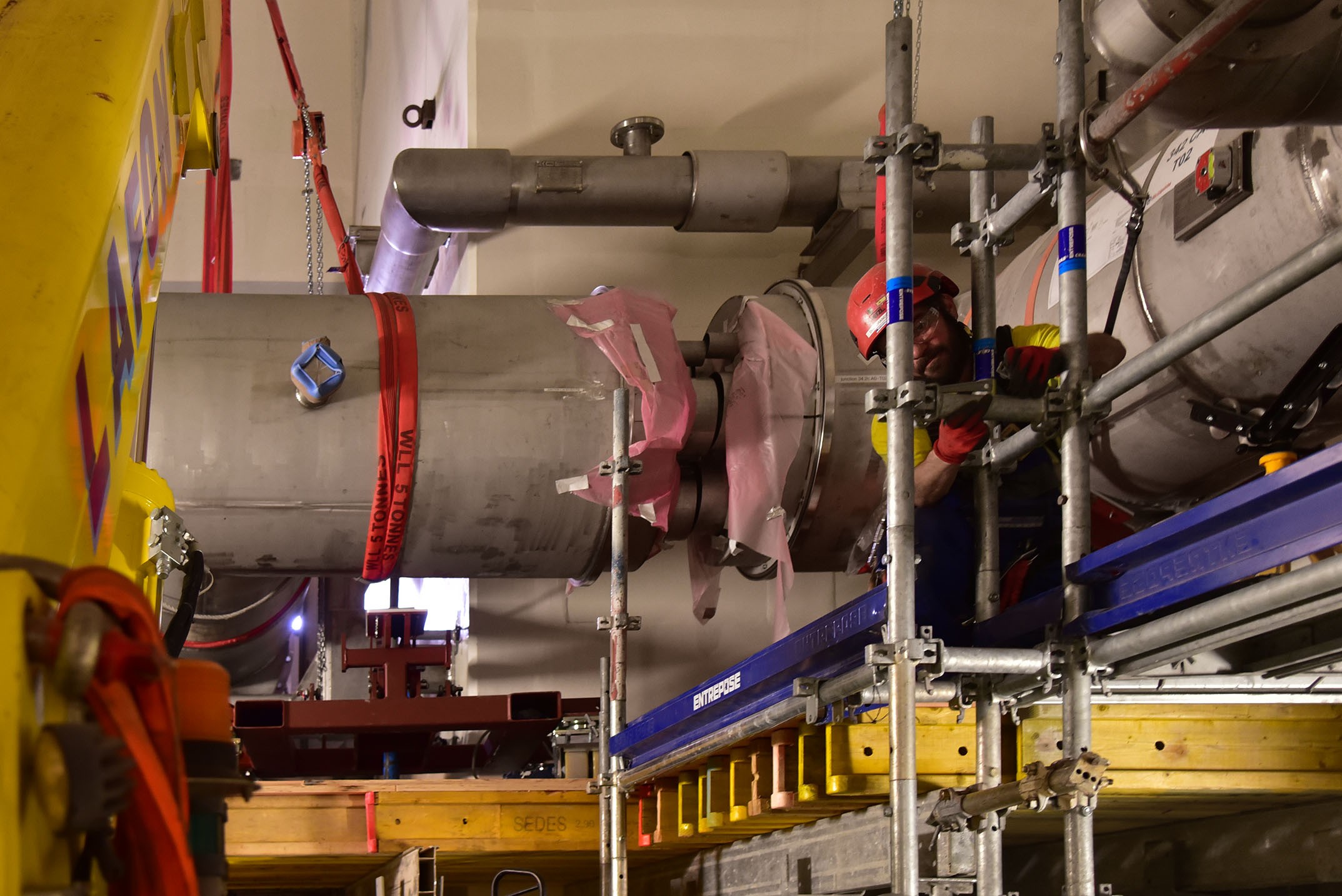

On Monday 17 October, a massive elbow-shaped cryoline spool was inserted into the sleeve of a pre-formed opening in the exterior wall of the Tokamak Building (Level 3). It will connect the cryolines installed inside that building to those coming from the cryoplant along the elevated "cryobridge."

Introducing a cylindrical object into a circular opening of corresponding diameter is something toddlers do all the time when they play with shape sorters. When the object is a delicate high-tech component that measures 8 metres in length, 1 metre in diameter and weighs in excess of 5.5 tonnes, things are a bit more complicated. A special crane—powerful, but small enough to operate in the congested environment of the Tokamak Building—needs to be brought inside. Then, as the load is attached to the tip of the telescopic boom, the crane's forward movements need to be as smooth as possible to avoid a "pendulum effect" that would be detrimental to the complex and delicate component. And finally, operators must be skilled enough to manoeuvre the crane and align the spool with the opening in the wall.

The operation was completed in less than 90 minutes. With the insertion of this strategic, elbow-shaped spool, the heaviest of the whole cryoline system, total cryoline installation inside the Tokamak Building is now close to 75% complete.