Midway through shield block procurement

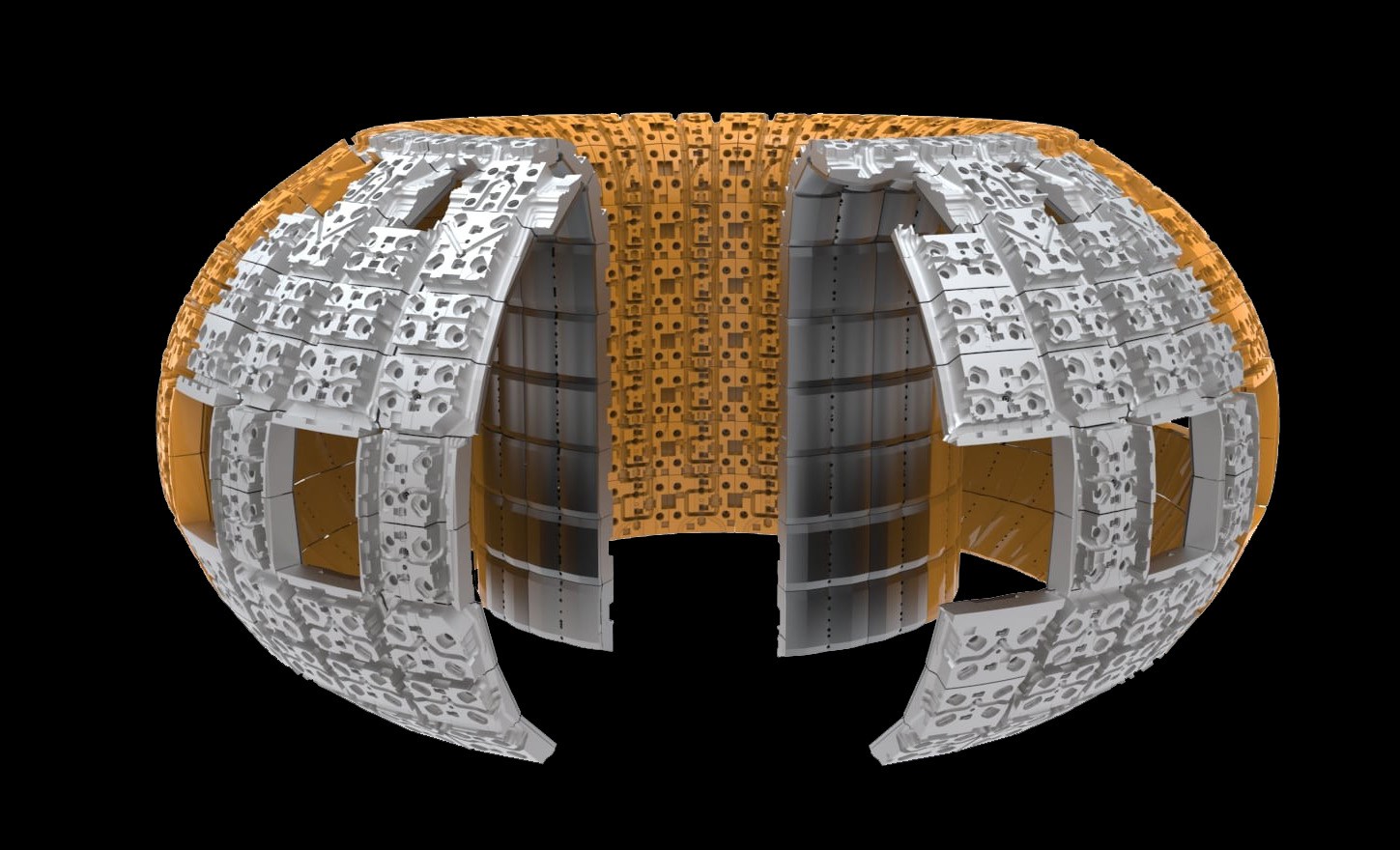

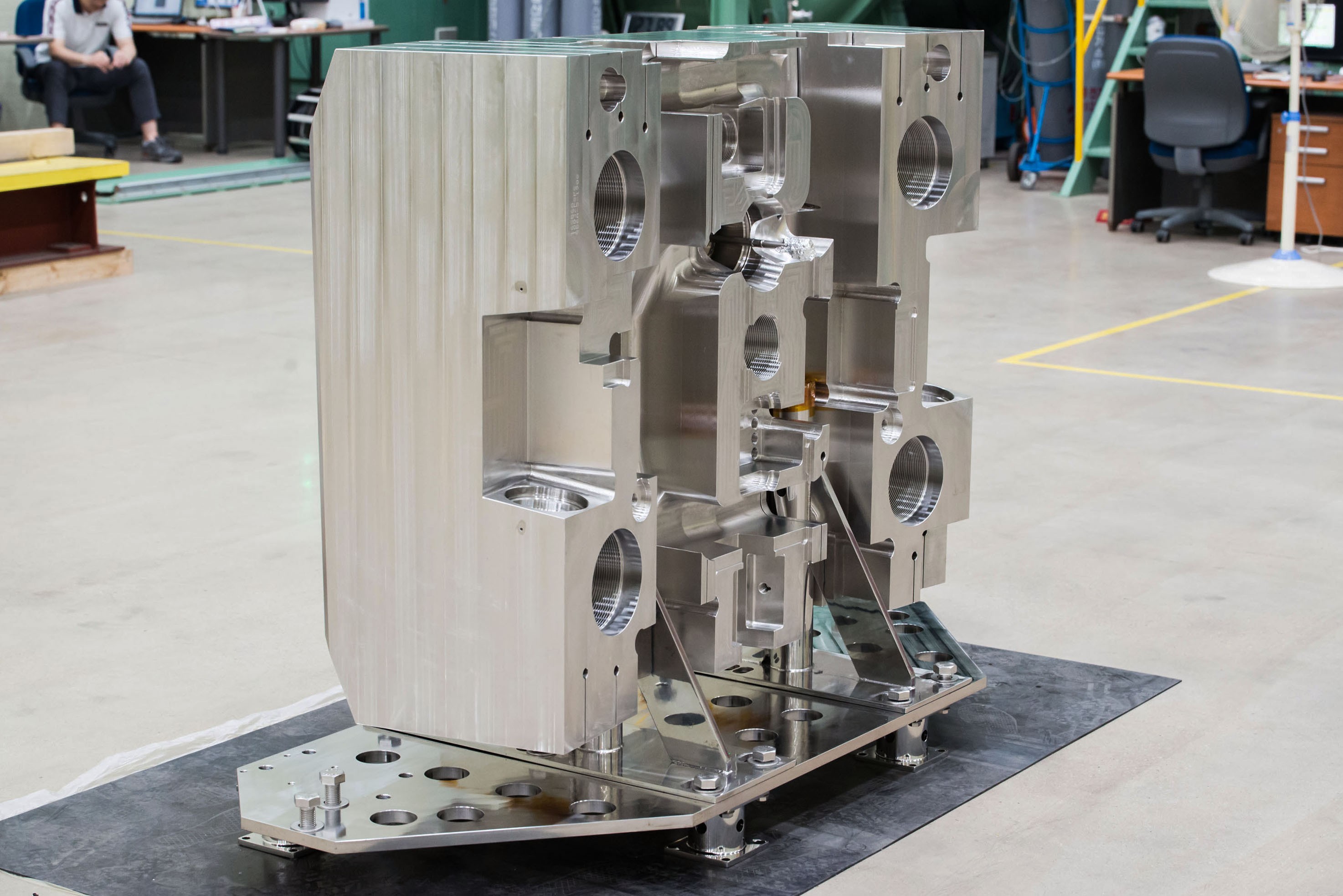

It all begins with a forged stainless-steel block weighing nine tonnes. As machining and deep-drilling operations commence, the rectangular block progressively loses heft and gains in complexity until, two years after entering the manufacturing line, the original piece of steel has been transformed into a highly complex component—a 2-metre-wide, 1.5-metre-tall, 50-centimetre-thick "shield block" weighing an average of 3 tonnes. In Korea and in China, where shield block procurement is underway, approximately 55 percent of fabrication is now complete.

"The dual mission of the shield blocks, their equipment, the many interfaces they integrate, and the extremely harsh environment to which they will be exposed explains their utter complexity, both in terms of internal cooling channels and outer geometry," says Fu Zhang, the ITER Technical Responsible Officer for the procurement who has been involved in shield block development since 2003. "Their integrity and efficiency, along with the functionality of the diagnostics equipment they accommodate, must be guaranteed despite conditions that combine ultra-high vacuum, nuclear irradiation, heat loads from the fusion reaction, and intense electromagnetic forces due to transient plasma events."

Added to these challenges are the more than one hundred design variations, which reflect the position of the individual shield block inside the vacuum vessel as well as the space requirements of interfacing systems such as plasma heating and diagnostics. "Executing the series production of such a demanding component is truly a world first. And we are succeeding!"

Last December in Guangzhou, China, a progress meeting was held at Dongfang Heavy Machinery, the main supplier for the Chinese shield block procurement. The work session—the 81st since 2013—brought together Fu Zhang, Frédéric Escourbiac (Deputy Head of ITER's Nuclear Technology Program), Ryan Hunt (Leader of the ITER Blanket Project) and representatives from the Chinese Domestic Agency and the Southwestern Institute of Physics (SWIP), which provides technical support. It was the first in-person progress meeting since pandemic-imposed restrictions in international travel.

"This long-delayed in-person meeting really made a difference," says Fu. "After four years of virtual exchanges, we were able to really reconnect with our colleagues and the personal interactions made it much easier to understand one another." What the ITER team saw at the Dongfang Heavy Machinery facility was most impressive: "A forest of shield blocks at different levels of manufacturing maturity, which we could examine and touch," says Escourbiac. "It provided a tremendous boost in motivation. The components looked like ready to be shipped and installed."

Had the team gone to EM Korea Co Ltd, where the Korean shield blocks are manufactured, or to Vitzrotech Ltd where they are tested, the feeling would have been the same. A little more than one decade after the Procurement Arrangements were signed in April 2013, series manufacturing of the first-of-a-kind components has now reached full capacity in both Korea and China. Out of a total of 220 shield blocks each, the first batch from Korea (90 units) should be delivered to ITER by mid-2025 followed half-a-year later by the first batch from China (106 units).