Third of the way there

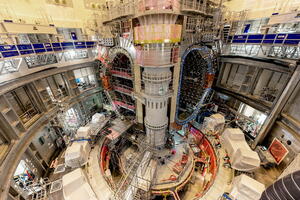

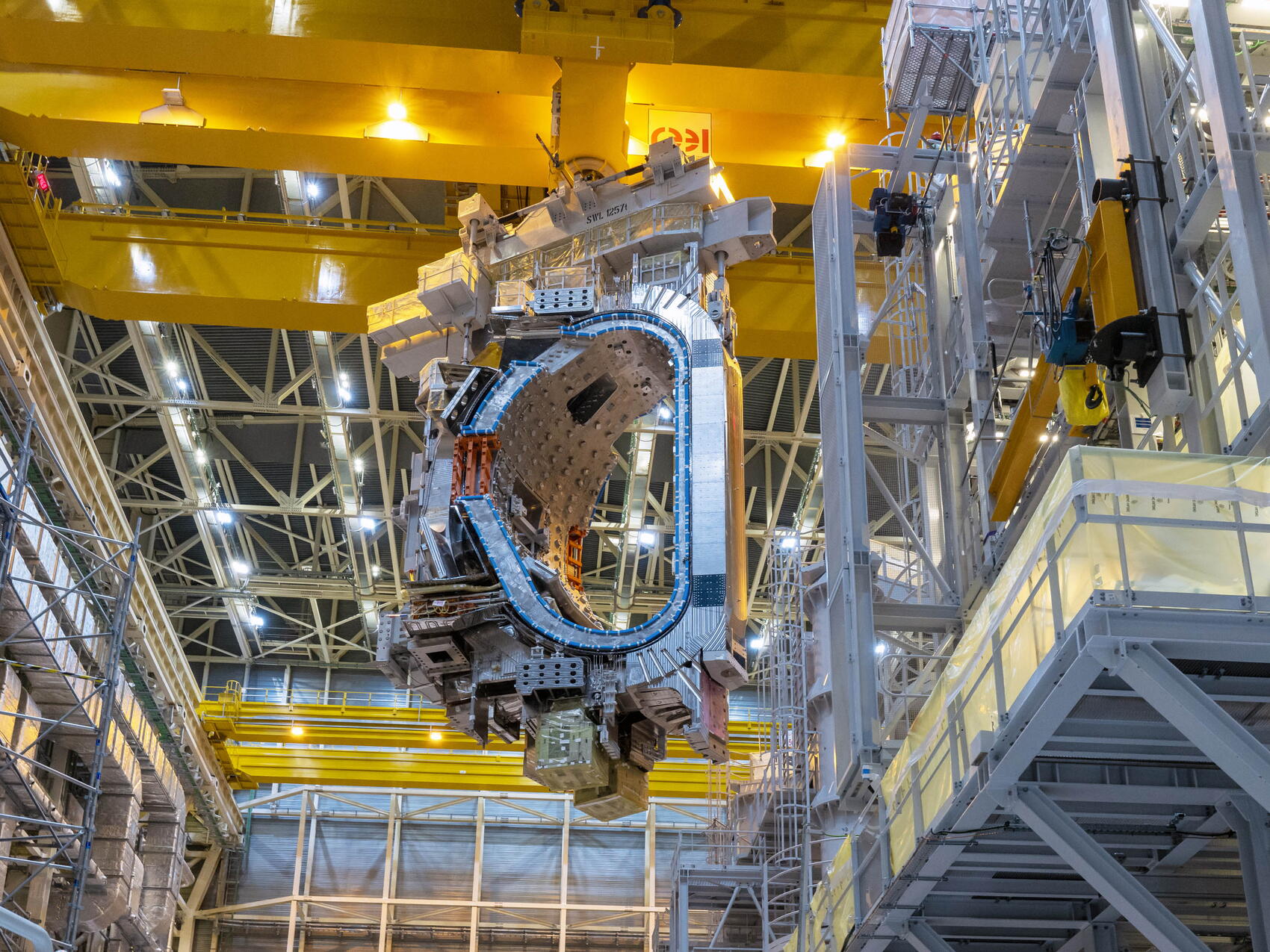

They say good things come in threes, and this was the certainly the case this week at ITER as the third sector module was successfully inserted into the tokamak pit.

The completion of the lifting operation for the almost 1,100-tonne component, which began on the afternoon of 24 November and ended on 25 November, means three of the vacuum vessel’s nine sector modules are now in place. Each sector module represents a 40° section of the plasma chamber and is composed of a vacuum vessel sector, its thermal shield, and two D-shaped superconducting magnets.

Sector module #7 and sector module #6 were placed earlier this year, but the operation for sector module #5 was unique in a number of ways—it was the first European-built sector to be installed in the pit; it also presented some new technological challenges.

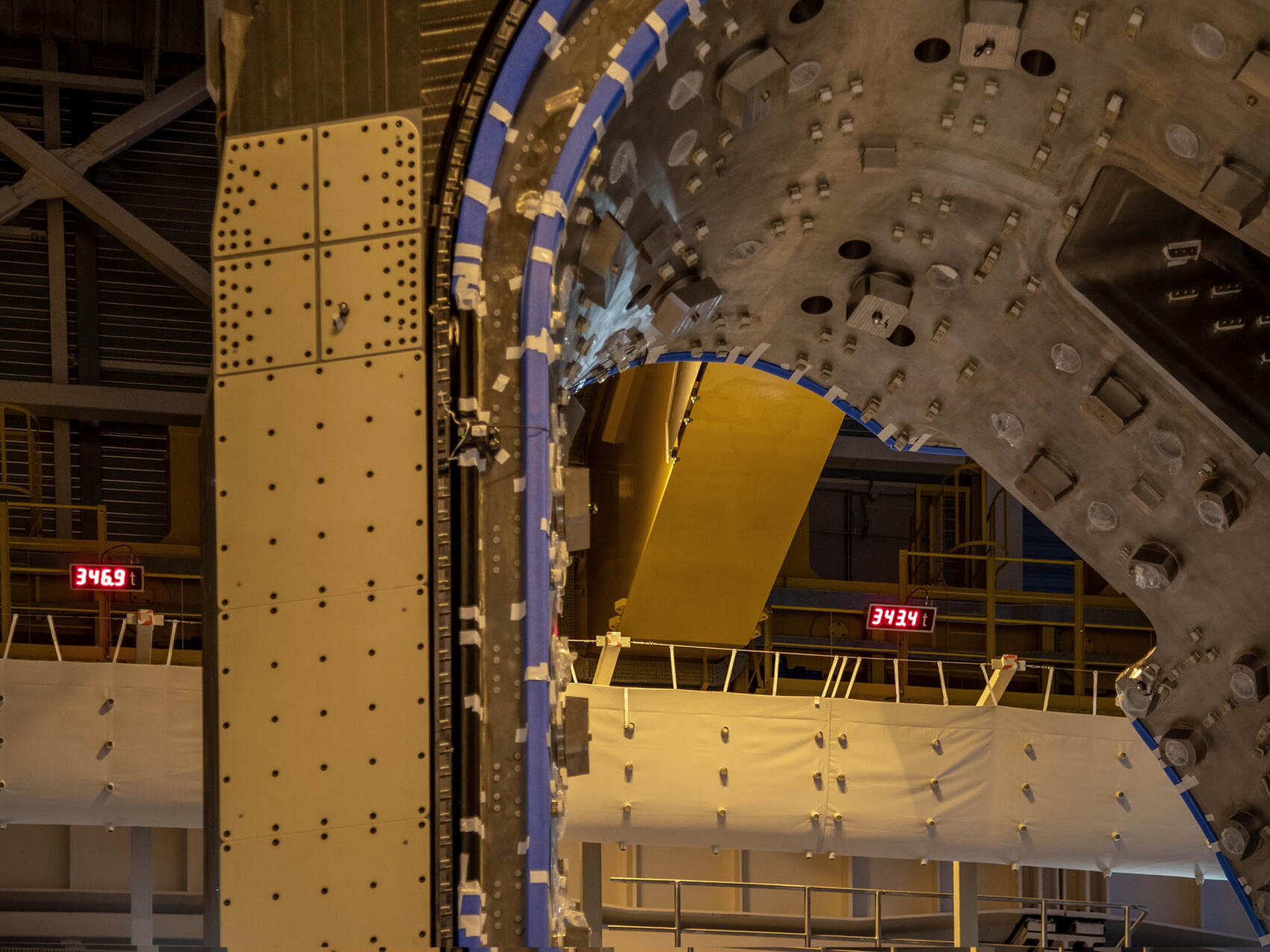

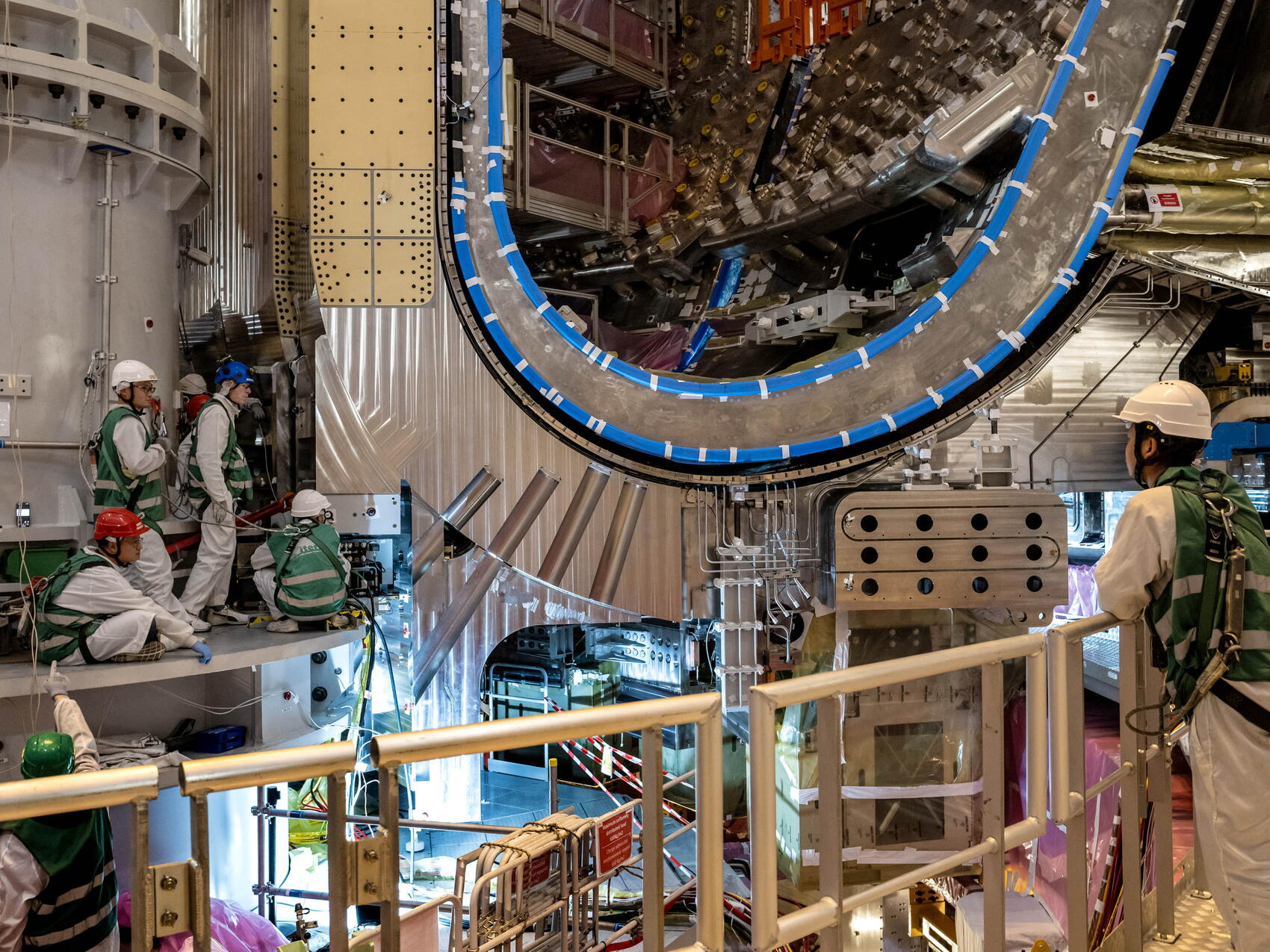

Challenge one was to reduce the offset when the module was lowered into the pit. In June, when module #6 was lowered into place beside module #7, an offset of 100 mm was left between the modules—a gap that was closed later. The objective for module #5 was to achieve tighter margins during installation to prepare for future operations when the pit is more crowded and little space remains. The team initially aimed for an offset of 50 mm between sector modules #6 and #5, but complications with the metrology systems opened a window of opportunity to try to be even more precise. Relying heavily on human observation, the team was able to land the module with approximately 10 mm of offset.

“It’s a big accomplishment,” says Mathieu Demeyere, the mechanical engineer at ITER who supervised the operation. “The team is tired but happy. It was a long night—with the modules so close to one another, we had a lot of decisions to make, but the experience was excellent preparation for future operations.”

The second challenge was to synchronize the lowering of the sector module with its vacuum vessel gravity support. Although nine are planned (for nine sector modules), the first gravity support was only installed last week, making sector module #5 the first test case. This meant that when sector module #5 was lowered the last few centimetres, the connection point of the gravity support had to be delicately angled to match with the interfacing component. The operation was successful and will be repeated for the next six sectors, while the two sectors already in place will have their gravity supports positioned retroactively.

With sector module #5 in place, Mathieu Demeyere and his team are now turning their attention to sector module #8, which is the next in line for installation in January 2026.

The sector module #5 lifting operation was closely observed by Jens Reich, ITER’s Machine Assembly Program Manager, who notes that efficiencies increase with every successful operation. “We’ve achieved a semi-industrial approach that is very important for vacuum vessel assembly and if it continues, we will complete sector installation on schedule in 2027.”