Image of the week

How cable became a coil

25 Nov 2019

We saw it being born, in the form of spooled lengths of jacketed conductor; we saw it being wrapped in white fiberglass tape and slowly transformed into a "double pancake" from multiple turns of insulated coil. Finally, we watched as the pancakes were impregnated with epoxy resin to create a rigid assembly.

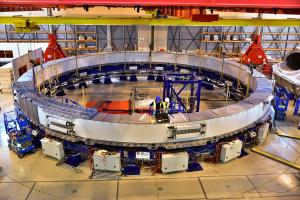

Preparing for vacuum pressure impregnation: the first sections of the mould (in grey) are being positioned on the winding pack. Poloidal field coil #5 (PF5), 17 metres in diameter, is the first coil produced by European Domestic Agency contractors in the winding facility on site. Winding began in April 2017.

Slowly, what was just jacketed conductor became a coil. Now, two and a half years after contractors to the European Domestic Agency began despooling operations, poloidal field coil #5 (PF5) has nearly reached the end of its fabrication process. In the photo above, the coil sits majestically on its supports as it is being prepared for vacuum pressure impregnation, an operation that will bond the insulation layers together and give the winding pack the necessary mechanical stiffness.

We'll have more on the ongoing works in the Poloidal Field Coil Winding Facility in an upcoming Newsline.