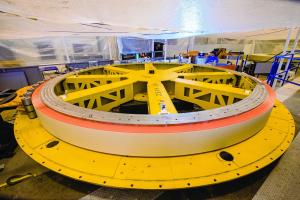

Six of nine completed

The European Domestic Agency is responsible for the fabrication of nine pre-compression rings (three top, three bottom and three spare). The first five have been successfully tested and delivered.

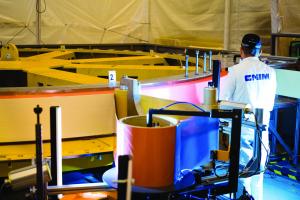

The first manufacturing steps take place at Exel Composites (Finland), where the fiberglass laminate used for the pre-compression rings is produced. The material is then delivered on spools (in lengths of 2.8 km) to CNIM in Toulon, France, where the team winds it along a helical circular trajectory and applies bonding tape between layers. Next comes curing at 65 °C, final machining and finally testing. The full process—now at maximum efficiency—takes a total of two months.