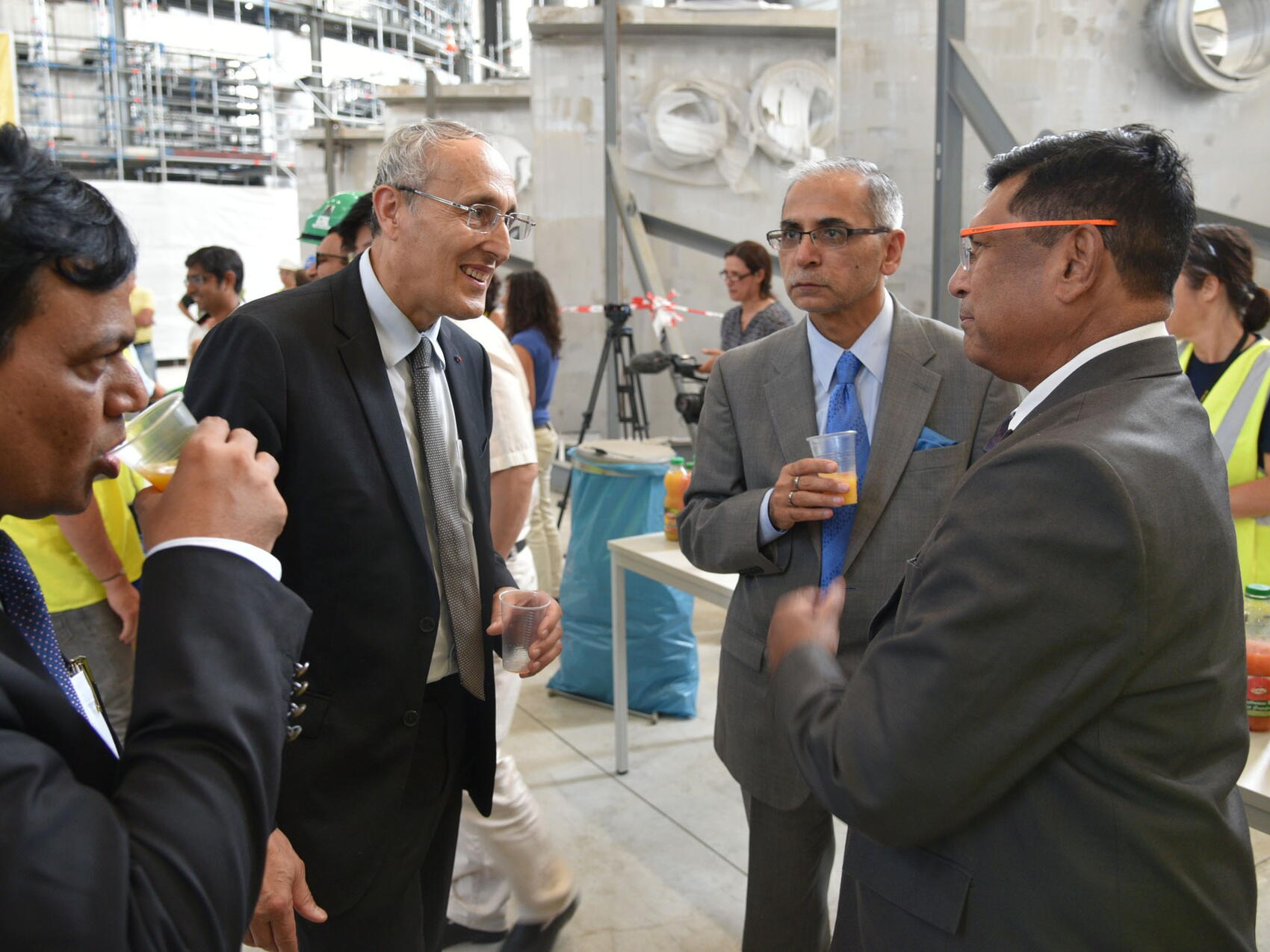

In the Cryostat Workshop, where the India-procured component is assembled and welded, ITER Director-General Bernard Bigot, India's Ambassador to France Vinay Mohan Kwatra, and the former chairman of the Atomic Energy Commission of India, Anil Kakodkar, symbolically smashed a bottle of French champagne on a large chunk of steel representing the ITER cryostat.

The ceremony marked an important milestone in the fabrication of this strategic component: two sections—the base and lower cylinder—are now completed and fully accepted by the ITER Organization, the upper cylinder is being assembled and aligned prior to welding, and half a world away, in the manufacturer's facility, the last segment of the "top lid" is being finalized.

The ITER cryostat is essential to the ITER machine, providing structural support and also acting as a thermos to insulate the Tokamak's magnetic system, at cryogenic temperature, from the warmth of the outside environment.

It is the largest vacuum vessel ever built—30 metres high, 30 metres in diameter, for a pump volume of 8,500 cubic metres. It is also a highly complex structure which must remain absolutely leak tight despite hundreds of "penetrations" that give passage to thousands of feedthroughs and lines for cryogenics, water, electrical power, diagnostics systems, and more.

In his address to the assembled guests, ITER Director-General Bernard Bigot retraced the "formidable technological, industrial and human venture" that the manufacturing of such a unique object represents. "Designing, manufacturing, delivering, assembling and welding this one-of-a kind component has proved a huge challenge for everyone involved."

And everyone involved was there, either in person or through video conference from India: the ITER cryostat team; representatives of ITER India, which is responsible for the procurement of the cryostat; industrial giant Larsen & Toubro Ltd, in charge of forging and machining the elements of the cryostat at its Hazira facility and assembling them on site; and finally the German company MAN Energy Solutions, subcontractor to Larsen & Toubro for on-site welding.